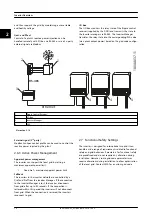

string combiner plus the length of the PV cables

included in the modules

•

The total length for the combined line is defined

as twice the physical distance between the string

combiner and the inverter

NOTICE

For the combined line, the maximum cable section

connectable to the inverter (95 mm

2

/ AWG 4/0) must be

addressed in the system design. If the calculated cable

section exceeds this limit, change the cable type, the

sub-plant size, or the location of the string combiners/

inverters.

Avoid looping the DC cables as they can act as an antenna

of radio-noise emitted by the inverter. Cables with positive

and negative polarity must be placed side by side with as

little space between them as possible. This also lowers the

induced voltage in case of lightning and reduces the risk

of damage.

4.2.2 Determining Sizing Factor for PV

Systems

When determining the PV system size factor, a specific

analysis is preferred, especially for large PV installations.

Local rules of thumb for choosing the sizing factor can be

determined, depending on local conditions, for example:

•

Local climate

•

Local legislation

•

System price level

To select the optimal configuration/sizing factor, an

investment analysis must be made. Large sizing factors

usually reduce specific investment costs (€/kWp) but could

have lower specific yield (kWh/kWp) due to derating losses

in the inverter (excessive DC power or overheating) and so,

lower income. Small sizing factors result in greater

investment costs. However, specific yield is potentially

greater due to little or no derating loss.

Installations in regions with frequent irradiation levels over

1,000 W/m

2

have lower levels of sizing factor than instal-

lations in regions with infrequent irradiance levels over

1000 W/m

2

. In particular, if high ambient temperatures are

not expected during the irradiance peaks.

A lower sizing factor must also be considered for tracking

systems, because they allow more frequent high irradiance

levels. In addition, derating due to overheating of the

inverter must be considered for tracking systems in hot

climates. This can also reduce the recommended sizing

factor further.

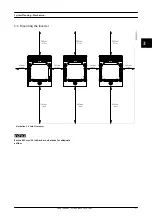

The MLX inverter supports different sizing factors,

depending on the number of modules per string and

number of strings per inverter.

Any configuration that observes the varying conditions for

different applications: the limits in

for short-circuit

current and open-circuit voltage will be considered as valid

and so covered by warranty.

4.2.3 Thin Film

The MLX inverter is a transformerless inverter without

booster and so the PV voltage is distributed symmetrically

to earth. Grounding of the minus pole is not allowed.

•

The use of transformerless inverters as MLX is

approved by many thin-film module manufac-

turers not requiring grounding of the minus pole

•

The MLX inverter is not compatible with thin-film

modules with a requirement of minus pole

grounding

NOTICE

It is important to get approval from the module

manufacturer before installing thin-film modules with

MLX inverters.

CAUTION

Module voltage during initial degradation can be higher

than the rated voltage in the data sheet. This must be

considered when designing the PV system, since

excessive DC voltage can damage the inverter. Module

current can also lie above the inverter current limit

during the initial degradation. In this case, the inverter

decreases the output power accordingly, resulting in

lower yield. Therefore, when designing, take inverter and

module specifications both before and after initial

degradation into consideration.

4.2.4 Internal Surge Overvoltage Protection

The MLX inverter includes high performance DIN-rail SPDs

in both AC (type II+III, according to IEC 61643-11) and DC

(type II) sides. The SPDs are easy to replace if damaged.

System Planning – Electrica...

22

L00410648-02_02 / Rev. date: 2014-10-03

4

4