4 Information on Maintenance

SMA America, LLC

20

SCCP-US-WH-US_en-31

Maintenance Manual

4 Information on Maintenance

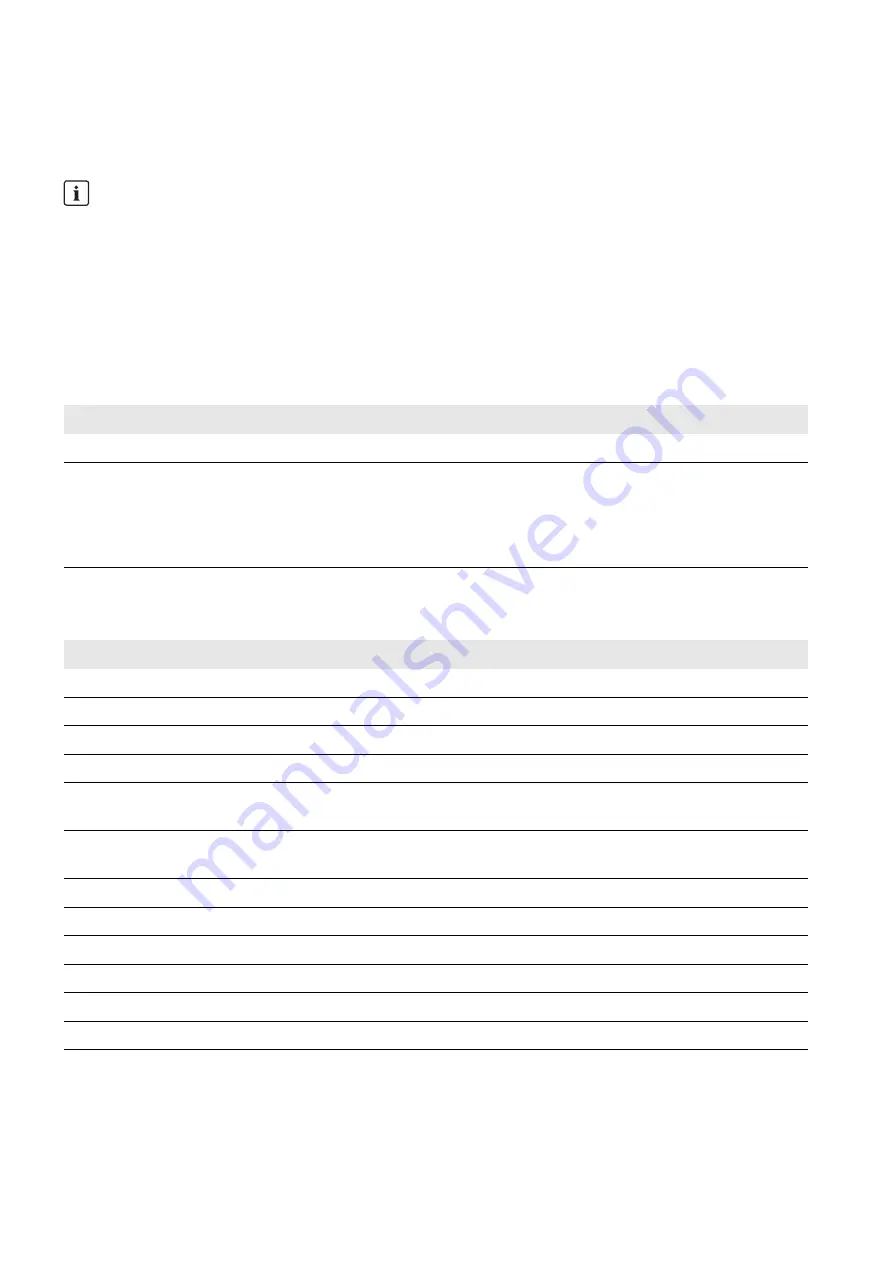

4.1 Maintenance Intervals

Maintenance under normal ambient conditions:

Preventive replacement intervals:

Shorter maintenance intervals in the event of adverse ambient conditions

The plant location and ambient conditions influence the maintenance intervals.

• If the inverter is installed in adverse ambient conditions, SMA recommends a monthly inspection in order to

determine the need for maintenance. The maintenance intervals are to be shortened depending on the

determined maintenance requirements. In particular, cleaning work and corrosion protection may be necessary

more frequently.

• Adherence to the maintenance intervals ensures trouble-free operation of the inverter (see the maintenance

report of the inverter).

Description

Interval

Maintenance

Every 24 months

AC circuit breaker

• Functional test*

• Cleaning*

• Checking the contact elements*

* See the manufacturer's maintenance manual of the AC circuit breaker

Every 24 months

Description

Interval

24 V Power Supply Units*

* Contact the SMA Service Line.

Every 10 years

24 V Buffer Modules

Every 10 years

Inverter Bridge Fan*

Every 12 years

Every 12 years

Integrated DC Switch motor actuated DC load-break

switches*

Every 15 years or 10,000 switching cycles,

whichever is sooner**

Integrated AC Disconnect GFDI / ABB High-Performance

After 100 trippings due to short circuit or after

7,000 switching cycles**

** The trippings and switching cycles are recorded as instantaneous values (see Section 5.1 "Reading the Replacement Interval Meter",

Remote Switch Unit of the GFDI*

After 7,000 switching cycles**

GFDI auxiliary signal contact*

Every 6 years

Cleaning Air Dict, Ventilation Grids and Air Inake

Regular

Surge arrester

If tripped

Key switch

In case of severe signs of wear

Label on the enclosure

If illegible, defective or not available

Summary of Contents for SC 500CP-US-10

Page 51: ......