-4-

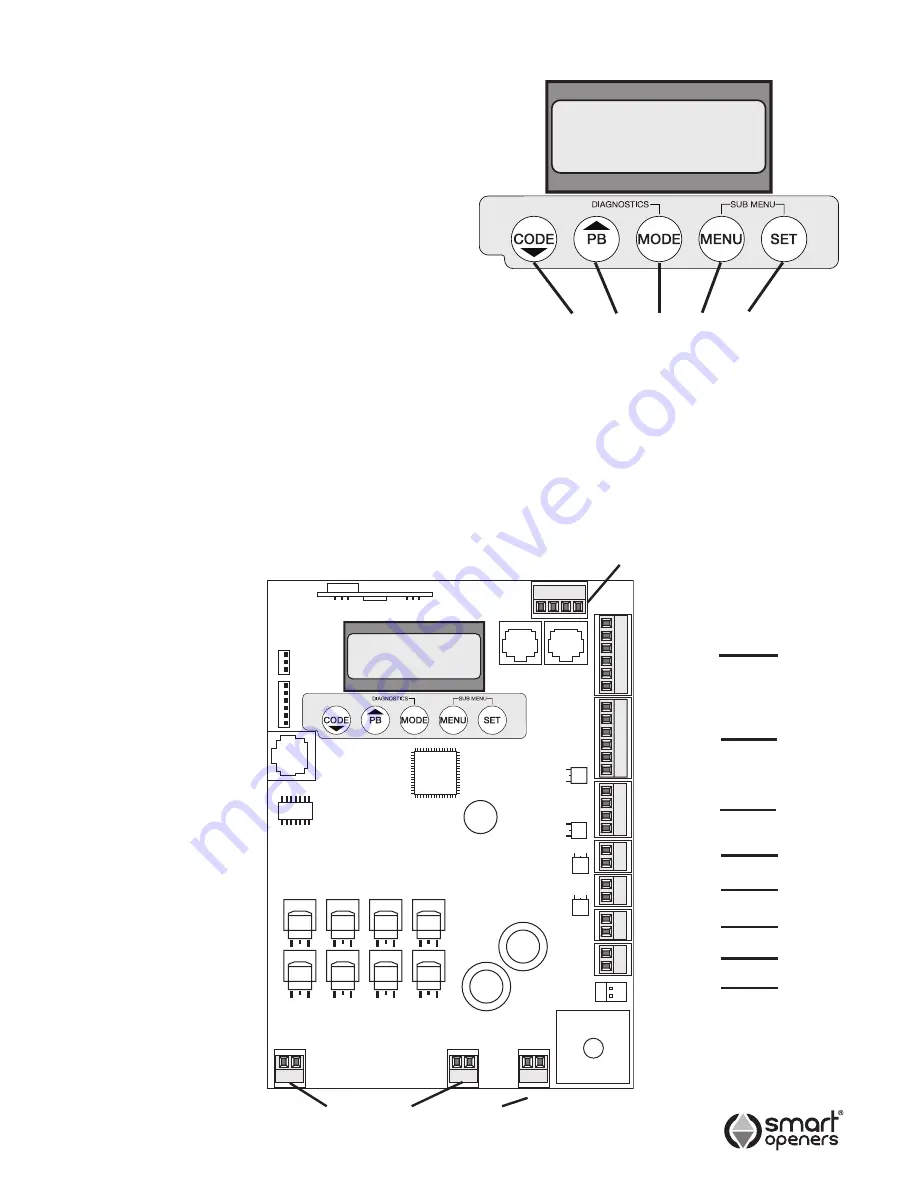

Operating Controls

1. CODE button - for coding transmitters.

2. P/B button - Open/Stop/Close.

3. MODE Button - Save setting and exit to normal

operation mode.

4. MENU Button - Function/Parameter select.

5. SET Button - Save changes and move to next

function.

Circuit Board Connectors

6. Connector for motor 1.

7. Connector for motor 2.

8. Connector for backup battery.

9 . Connector for encoders.

10. Connector for controlling inputs.

11. Connector for motor limits input.

12. Connector for photo beam.

13. Connector for pulse/magnetic lock.

14. Connector for DC flashing light or similar (5A max).

15. Connector for DC courtesy light or similar (5A max).

16. Connector for solar panel or external DC charger.

17. Connector for controller power from transformer.

1 2 3 4 5

6

7

8

Com

Push Btn

Pedestrian

Stop

Close

Open

M2 Open Limit

Com

M2 Close Limit

M1 Open Limit

Com

M1 Close Limit

Com

Photo Beam 2

Photo Beam 1

+24V

Lock +

Lock -

Activity 2 +

Activity 2 -

Activity 1 +

Activity 1 -

DC Charger -

DC C

24V AC

- Encoder 2 Encoder 1 +

Encoder 2 Encoder 1

Motor 1

Motor 2

24V Battery

Back Up

RS-232

Interface for site

maintenance

Smart Openers

SC Vx.xx

9

10

11

12

13

14

15

16

17

RF Receiver

© June 2009 Smart Openers Pty Ltd

Smart Openers

SC Vx.xx