3.1 Power connection

The swing is required to connect two cores wires, which requires very low voltage that no

professinally trained personnel is required in installation; however, the users are advised to read

the installtion manual carefully before going for it. After getting to know all accessories and

their positions, suggest starting from cable conduit arrangement to prevent the cables from being

broken or damaged.

3.2 Notes for Power Connection

A. The installation of power supply cable to the motor should be carried out by a qualified

professional electrician.

B. The power supply cable of the motor should be equipped with short circuit protection and

leakage protection. Please make sure to shut off the power before going installtion or maintenance.

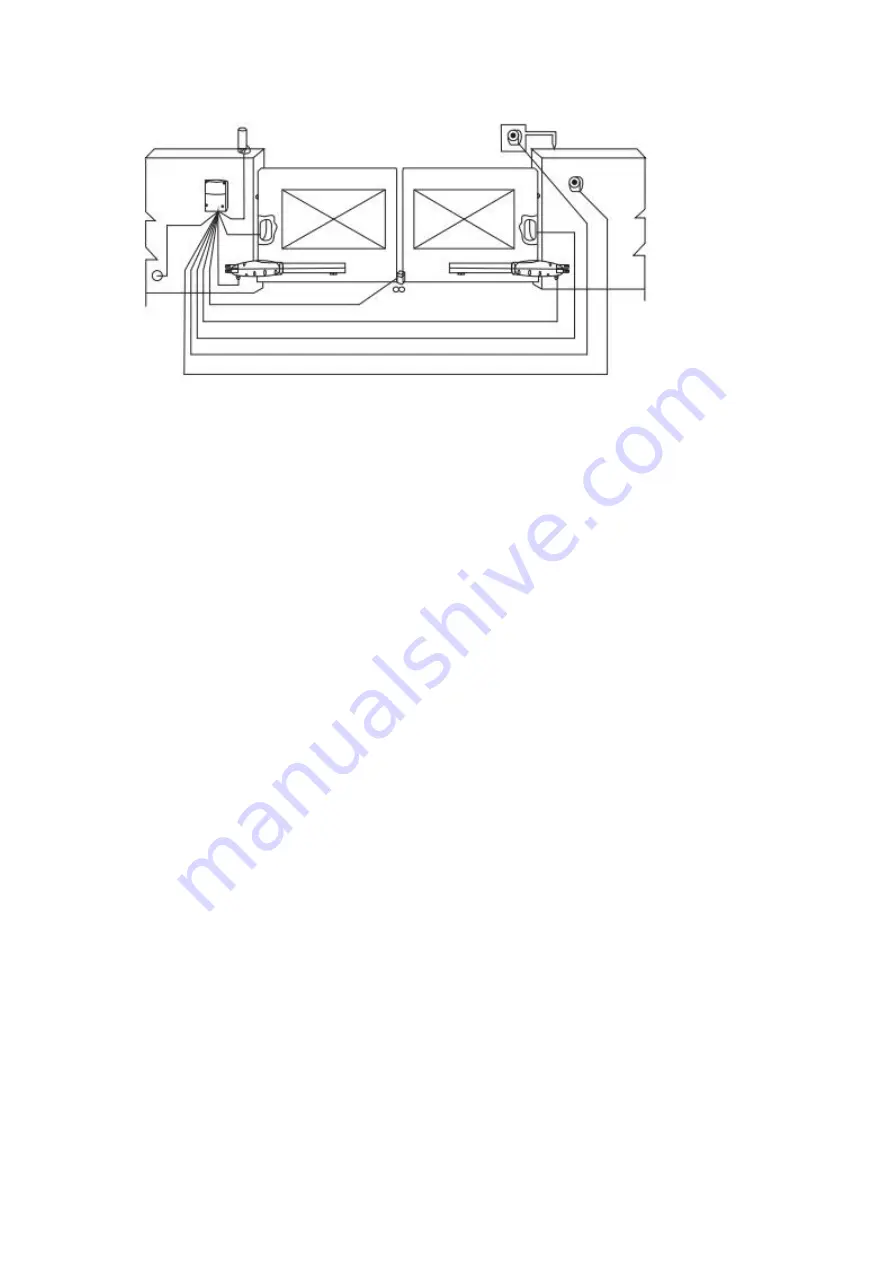

4. Installation

4.1 Preparation for Motor Installation

The gate motor is not applicable to a gate which is ineffcient or unsafe, neither to solve the defects

due to incorrect installation nor poor maintenance.

Check the following items before going for installtion:

1) Make sure the weight and dimension of the gate conform to the operation range of the gate

motor. Don’t use the gate mootr if the gate specifications do not meet the requirements.

2) Make sure the gate structure conform to the criteria of automatic operation and force

regulations.

3) Make sure there is no serious friction existing in the opening or closing travel of the gate

leaves.

4) Make sure the gate is at horizontal level that the gate will not move aside at any position.

5) Make sure the gate can bear the impact of the motor torque when it is installed on any hole of

the bracket which the surface is sufficiently sturdy.