Version 6.00

Date of editing: 16.09.2022 r.

Page 6 of 10

Installation manual

KTS

III.

INSTALLATION TECHNOLOGY

–

FLEXIBLE WALL

a.

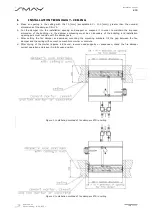

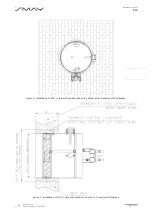

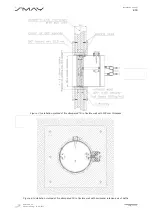

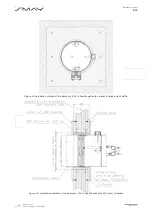

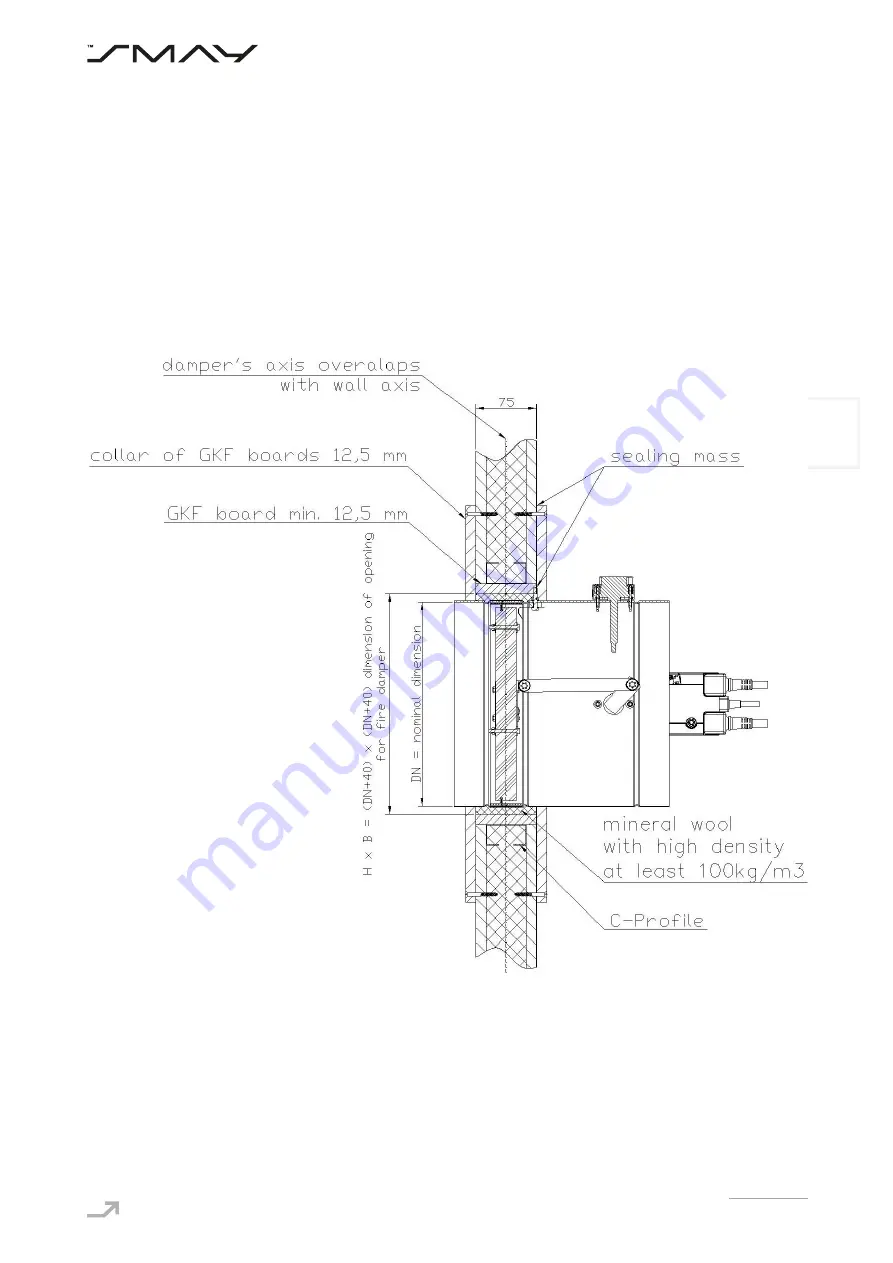

Make an opening in the wall with the 70 [mm] (acceptable 6

0 ÷

100 [mm]) greater than the nominal

dimensions of the fire damper: B=DN+70 and H=DN+70.

b.

Put the damper into the installation opening and support or suspend it in order to maintain the imposed

dimension of the building i.e. the damper embossing must be on boundary of the building, and installation

opening axis must coincide with fire damper axis.

c.

After setting the fire damper as described, fill the gap between the fire damper and the wall with non-flammable

mineral wool of high density, 100 kg/m

3

or more.

d.

Seal the place of filling with mineral wool using the sealing compounds: Hilti Firestop Coating CP 673,

Promastop-Coating, Promaseal-Mastic or Soudal Firesilicone B1 FR.

e.

Mount collar, both side of wall, made of GKF boards, 12,5 [mm] thick and DN+ 350 [mm] wide, using screws

(with the hole for the damper cutted out). For easy assembly, the collar can be made of two parts.

f.

After mounting the collar, remove the supports or suspensions, check the fire damper correct operation and

leave it in open position.

Figure 6. Installation of KTS in flexible wall construction with 75 [mm] thickness