Wersja 1.00

Data edycji: 16.09.2022 r.

Strona 19 z 35

Dokumentacja techniczno-ruchowa

KWP-P-E

7.2.

INSTALLATION TECHNOLOGY - CEILING

PROMAT self-supporting duct:

a.

Make an opening in the ceiling with the 100 [mm] (acceptable 80 ÷ 120 [mm]) greater than the nominal

dimensions of the fire damper = B+100 and H+100. In case of other dimensions than B+100 x H+100, adjust

dimensions of mounting brackets.

b.

Put the closed fire damper into the wall on the depth marked by undercuts on the damper body (dimension

60mm)

c.

After setting the fire damper as described, with use mounting brackets, fill the gap between the fire damper and

the wall with cement, cement-lime mortar, concrete or with use mineral wool with density greater than

100kg/m

3

(item 1).

d.

Mount the mounting brackets properly:

Side length up to 500 mm

–

1 pcs.

Side length from 500 to 800 mm

–

2 pcs.

e.

Make the duct with 50 mm thick PROMATECT-L500 panels (item 3).

f.

Make a band around the duct with 50 mm thick, 60 mm width PROMATECT-L500 panels (item 4).

g.

Make a band around the duct (under ceiling) with 20 mm thick, 200 mm width PROMATECT-H (item 5).

*This

band is required only when mineral wool was used to seal the damper in point 3.

h.

Make a connection between the duct and ceiling likewise the duct with the band using glue K84.

i.

Connect the sides of the channel and sides the band with use screws 4.2x90 - 4.8x120.

j.

Housing montage with actuator similarly as in the picture. Only the length of the mounting brackets will change.

Mount the mounting brackets to the ceiling using raw bolts.

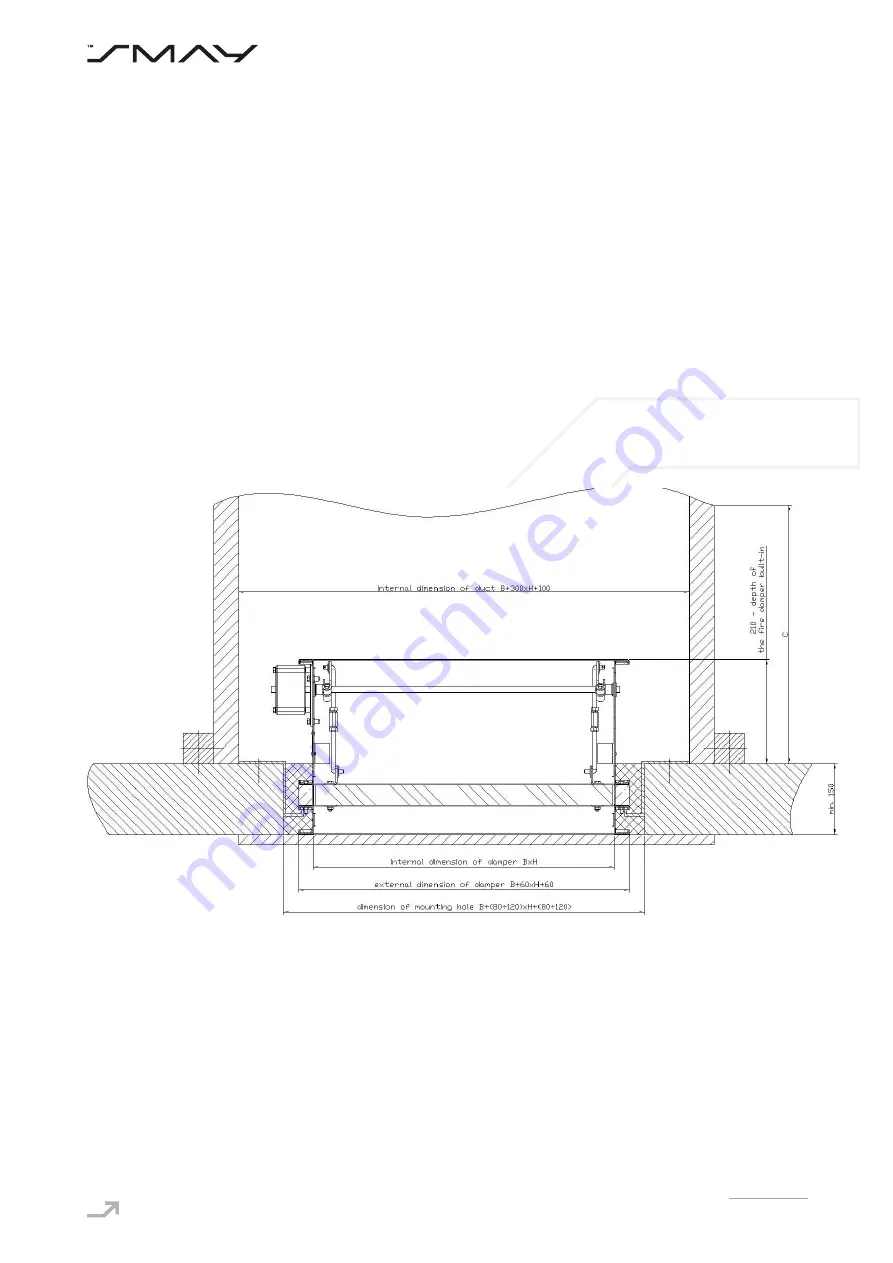

Figure 7. Installation method of fire dampers KWP-O in ceiling with a duct made of PROMAT boards with sealing of

mineral wool