HRX-OM-R016

Chapter 5 Display and setting of various functions

HRS Series

5.5

Inspection monitor menu

5-11

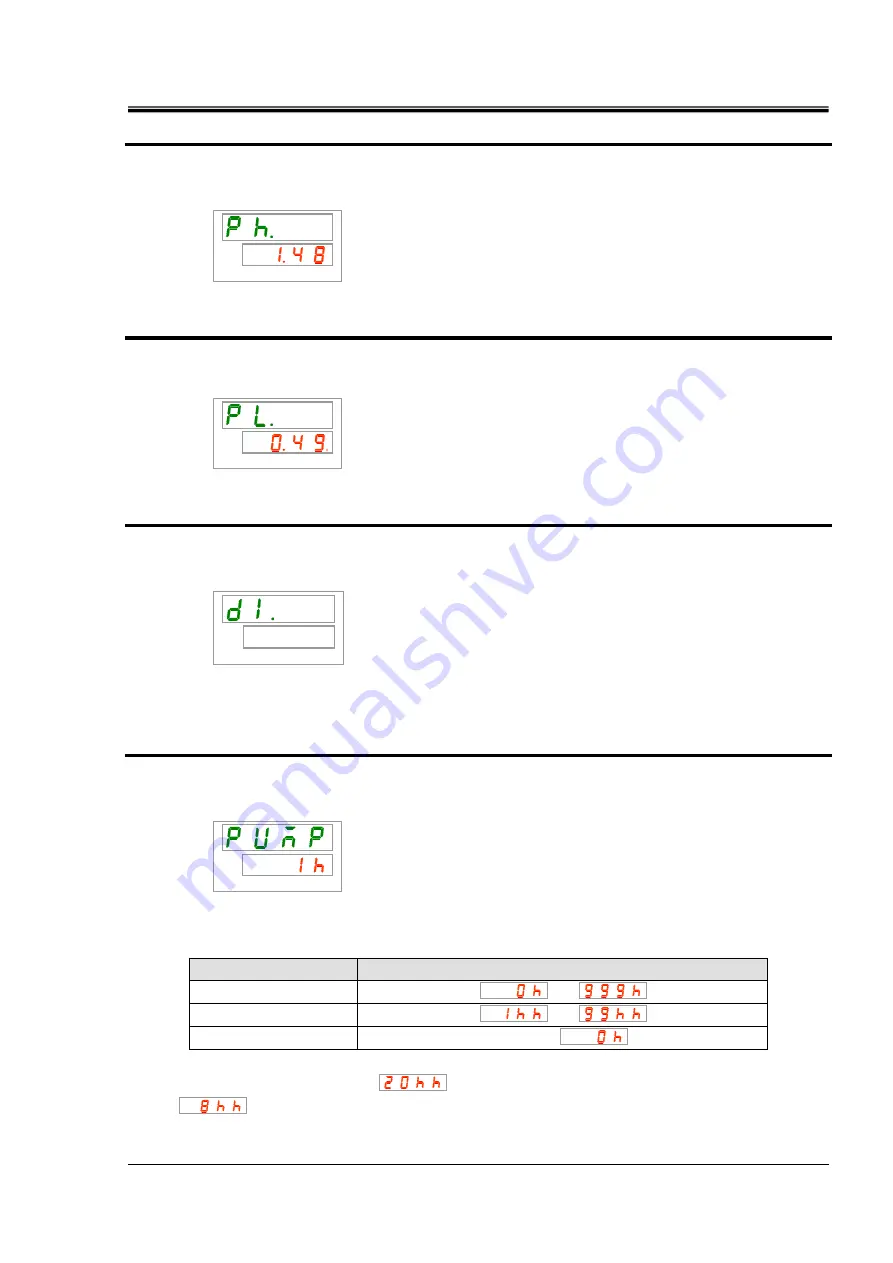

Check of the pressure of the higher pressure side of the refrigerant circuit

5.

Press the [SEL] key once.

The pressure of higher pressure refrigerant circuit is displayed on the digital display.

Displays the pressure of the higher pressure side of the refrigerant circuit.

Check of the pressure of the lower pressure side of the refrigerant circuit

6.

Press the [SEL] key once.

The pressure of lower pressure refrigerant circuit is displayed on the digital display.

Displays the pressure of the lower pressure side of the refrigerant circuit.

Check of the electric resistivity/conductivity

7.

Press the [SEL] key once.

The electric resistivity/conductivity is displayed on the digital display.

This function is available for customers who have purchased the electric

resistivity/conductivity sensor set which is a separately sold accessory. Refer to the

Operation Manual attached to these optional accessories for details.

Check of the accumulated operation time of the pump

8.

Press the [SEL] key once.

The accumulated operation time of the pump is displayed on the digital display.

Displays the accumulated operation time of the pump. Refer to the table below for the

display.

Table 5.5-2 List of time display

Cumulative time

Indicated value

0h to

999h

to

1,000h to 99,999h

to

100,000h

Return to

AL28 Pump maintenance alarm is generated when the accumulated operation time of the

pump reaches 20,000 hours (

) or more.

【

In the case Option T, 8,000 hours

(

) or more

】

For details, refer to Chapter 7

Alarm indication and trouble shooting

PV

SV

PV

SV

PV

SV

PV

SV