- 10 -

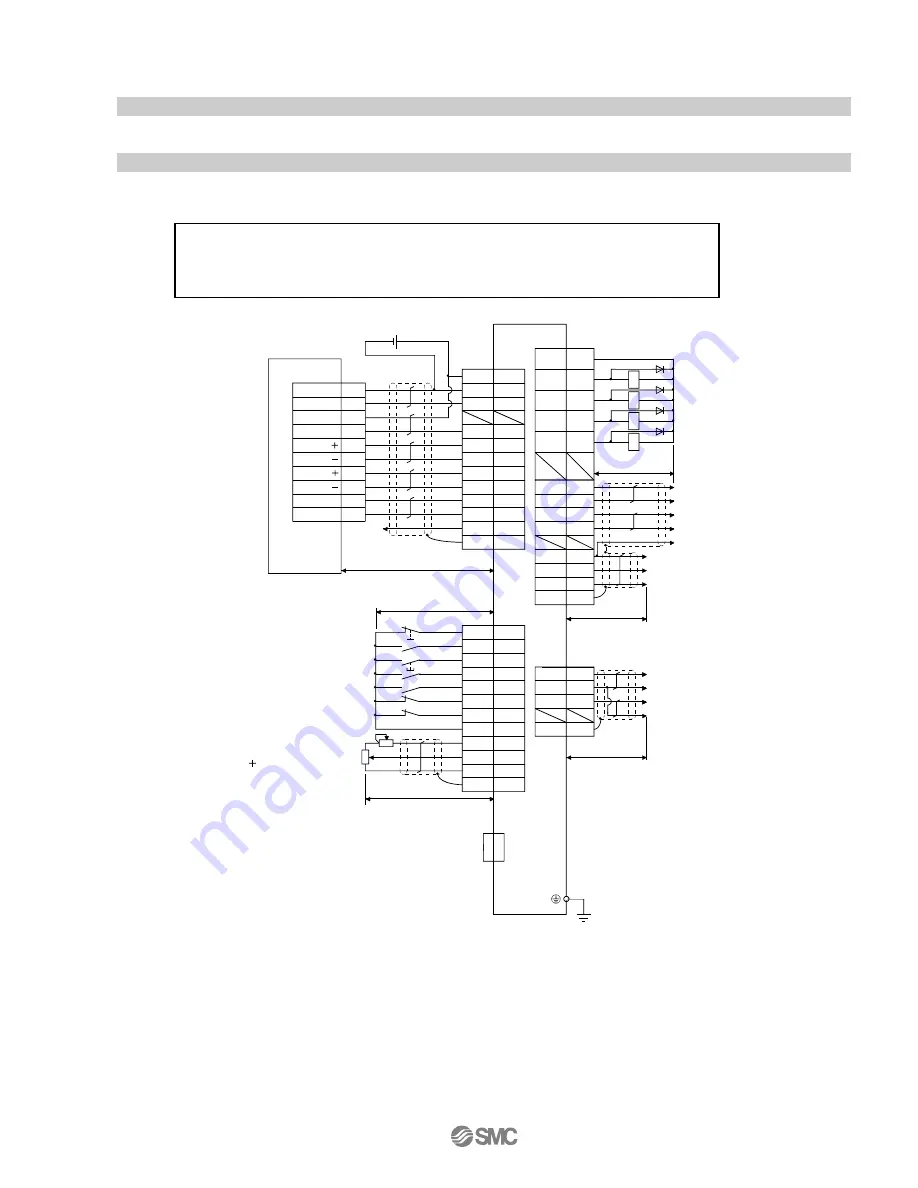

3.2 I/O signal connection for each mode

The example of connecting driver's I/O signal is shown.

3.2.1 Position control mode (Sink I/O interfaces)

(1) Connection example

A connection example of the position control mode is shown below. Connect wires if necessary.

(Note 12)

Plate

Plate

Servo amplifier

3

1

2

(Note 7)

CN6

(Note 2)

Trouble (Note 6)

Zero speed detection

Limiting torque

Encoder A-phase pulse

(differential line driver)

21

DICOM

48

ALM

23

ZSP

25

TLC

24

INP

4

LA

5

LAR

6

LB

7

LBR

34

LG

33

OP

1

P15R

SD

10m max.

2m max.

Encoder B-phase pulse

(differential line driver)

Control common

Encoder Z-phase pulse

(open collector)

(Note 7)

CN1

LG

DICOM

10m max. (Note 8)

41

20

46

49

10

11

35

9

3

36

CLEARCOM

12

15

16

14

13

11

CLEAR

RDYCOM

READY

PULSE F

PULSE F

PG0

PG0 COM

PULSE R

PULSE R

18

10

17

9

DOCOM

CR

RD

PP

PG

NP

NG

LZ

LZR

8

(Note 11)

(Note 7)

CN1

QD75D

Positioning module

24VDC

In-position

(Note 4, 12)

Control common

SD

RA1

RA2

RA3

RA4

Plate

(Note 1)

2m max.

10m max.

Upper limit setting

42

15

19

17

18

43

44

47

1

27

SD

EMG

SON

RES

PC

TL

LSP

LSN

DOCOM

P15R

TLA

LG

28

(Note 7)

CN1

Emergency stop

Servo-on

Reset

Proportion control

External torque limit selection

Forward rotation stroke end

Reverse rotation stroke end

(Note 3, 5)

(Note 5)

(Note 10)

USB cable

(option)

(Note 9)

MR Configurator

CN5

Analog torque limit

10V/max. torque

Personal

computer

(Note 12)

Plate

MO1

LG

MO2

SD

2m max.

Analog monitor 1

Analog monitor 2

Refer to

“LECSB Operation Manual”, section 3.2 for wiring details.

Refer to

“

LECSB Operation Manual (

Simplified Edition)”, section 3.2.1 (2) and (3) for input/output signal details.

This is the wiring example using PLC of Mitsubishi Electric (QD75D) used for

position control mode.

(Connection example of the differential receiver system)

Refer to the operation manual of LECSB and the technical data and the

operation manual of PLC and positioning unit.

Driver

Controller