-

7

-

3-3.

Mounting

Caution

①

Be certain to match the rod shaft center with the load and direction of movement when

connecting.

When not properly matched, problems may arise with the rod and body, and damage may be caused due to

friction on areas such as the inner body surface, bushings, rod surface, and seals.

②

When an external guide is used, connect the rod end and the load in such a way that there is no

interference at any point within the stroke.

③

Do not scratch or gouge the sliding portion of the cylinder body or the piston rod by striking it

with an object, or squeezing it.

The body bore is manufactured under precise tolerances. Thus, even a slight deformation could lead to a

malfunction.

Moreover, scratches or gouges, etc. in the piston rod may lead to damaged seals and cause air leakage.

④

Prevent the seizure of rotating parts.

Prevent the seizure of rotating parts (pins, etc.) by applying grease.

⑤

Do not use until you verify that the equipment can operate properly.

After mounting, repairs, or modification, etc., connect the air supply and electric power, and then confirm

proper mounting by means of appropriate function and leak tests.

⑥

Instruction manual

Install the preducts and operate them only after reading the instruction manual carefully and understanding its

contents. Also keep the manual where it can be referred to as necessary.

⑦

Set the mounting base suitable to large force given by the cylinder.

If the mounting base doesn’t have enough hardness, the human and the device may be damaged.

⑧

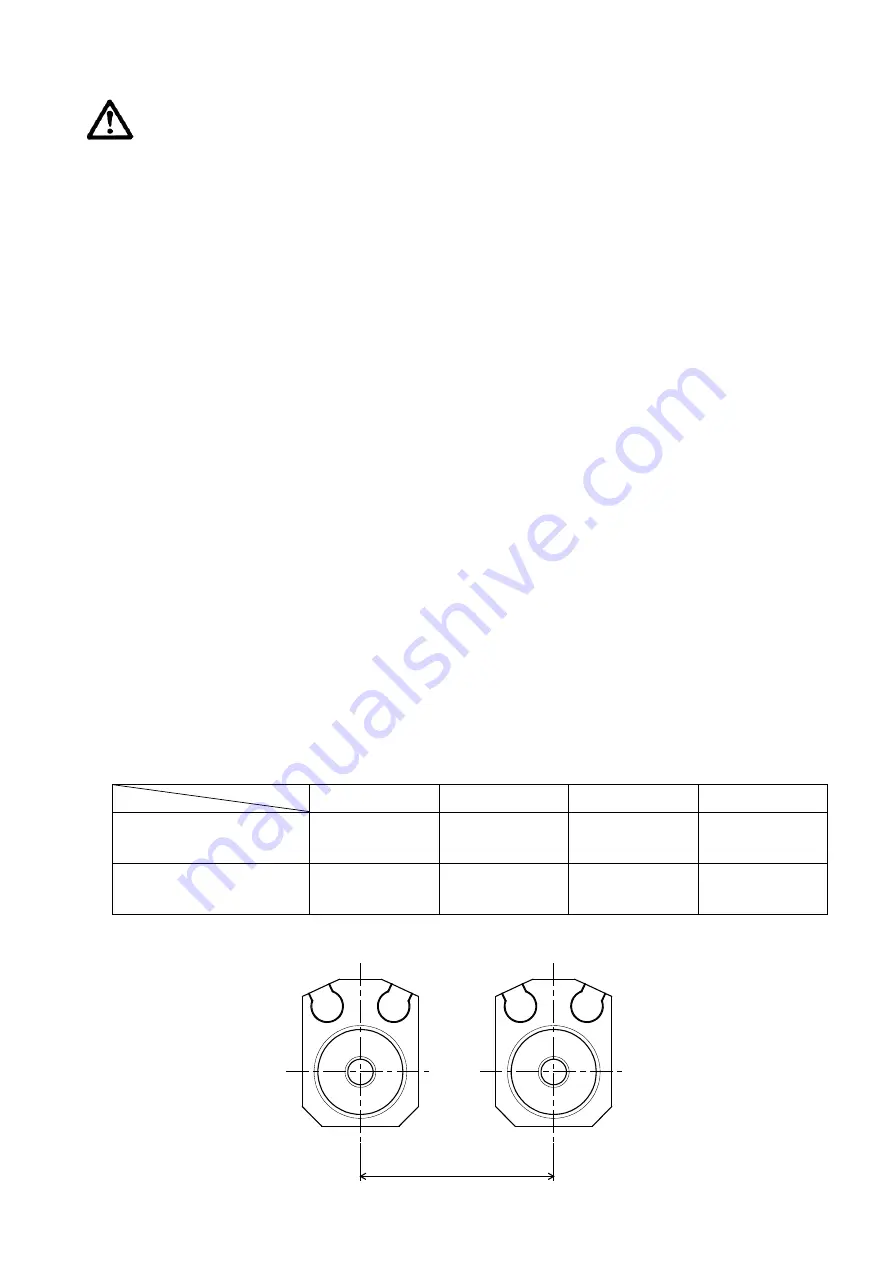

If auto switch cylinders are used in parallel keep the distance between cylinders in accordance

with the chart below.

(mm)

Φ

4

Φ

6

Φ

10

Φ

16

D-A9

□,

D-A9

□

V

―

20

25

30

D-M9

□,

D-M9

□

V

D-M9

□

W

,

D-M9

□

WV

25

25

30

35

Use caution not to use them, getting closer than the specified pitch.

Otherwise, it may cause auto switch to malfunction.

Mounting pitch