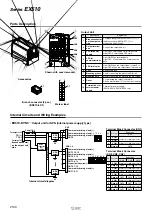

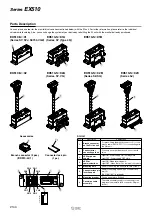

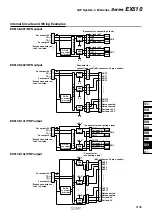

Series

EX510

Specific Product Precautions 1

Be sure to read before handling.

1. Do not drop, bump, or apply excessive im-

pact.

Otherwise, the unit can become damaged, malfunction, or fail

to function.

2. Hold the body while handling this product.

Otherwise, the unit can become damaged, malfunction, or fail

to function.

3. Observe the tightening torque range

Tightening outside of the allowable torque range will likely

damage the product.

4. Do not install a unit in a place where it can

be used as a scaffold.

Applying any excessive load such as stepping on the unit by

mistake or placing a foot on it, will cause it to break.

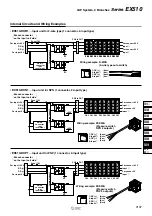

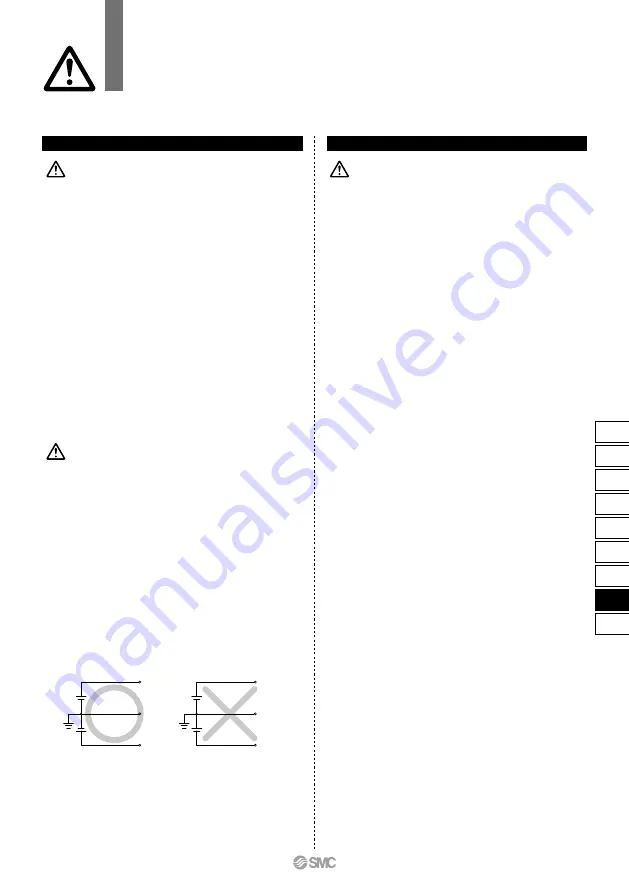

+24 V

0 V

+24 V

Power supply for

the input and for

the control unit

of the Gateway

Power supply

for output

+24 V

0 V

–24 V

Power supply for

the input and for

the control unit

of the Gateway

Power supply

for output

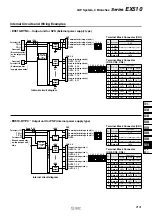

Design and Selection

1. Use within the allowable voltage range.

Using beyond the allowable voltage range is likely to cause the

units and connecting devices to be damaged or to malfunction.

2. Do not use beyond the specifications range.

Using beyond the specifications range is likely to cause a fire,

malfunction, or breakdown in the units and connecting

devices. Check the specifications before handling.

3. Establish a backup system beforehand,

which employs fail-safe concepts such as

multiple equipment and devices to prevent

breakage or malfunction of this product.

4. Provide an external emergency stop circuit

that will immediately stop an operation and

cut off the power supply.

5. When using for an interlock circuit:

• Provide a double interlock which is operated by another

system (such as mechanical protection function).

• Perform an inspection to check that it is working properly

because it can cause possible injuries.

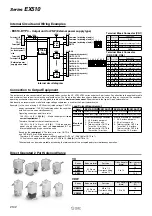

1. Keep the surrounding space free for mainte-

nace.

When designing a system, take into consideration the amount

of free space needed for performing maintenance.

2. When applicable to UL, use a Class 2 power

supply unit conforming to UL1310 for DC

power supply.

3. This product is one of the components to be

equipped into a final equipment. Confirm the

adaptability to the EMC directive as the

whole equipment by customers themselves.

4. The power supply for the Gateway unit

should be 0 V as the standard for both power

supply for outputs as well as inputs and for

the control unit of the Gateway.

Mounting

Warning

Caution

Caution

2151

EX12

EX140

EX180

EX260

EX250

EX600

EX500

EX510

PCA

EX

EX510