-13-

No.EX

※※

-OMU1021-A

■

Wiring

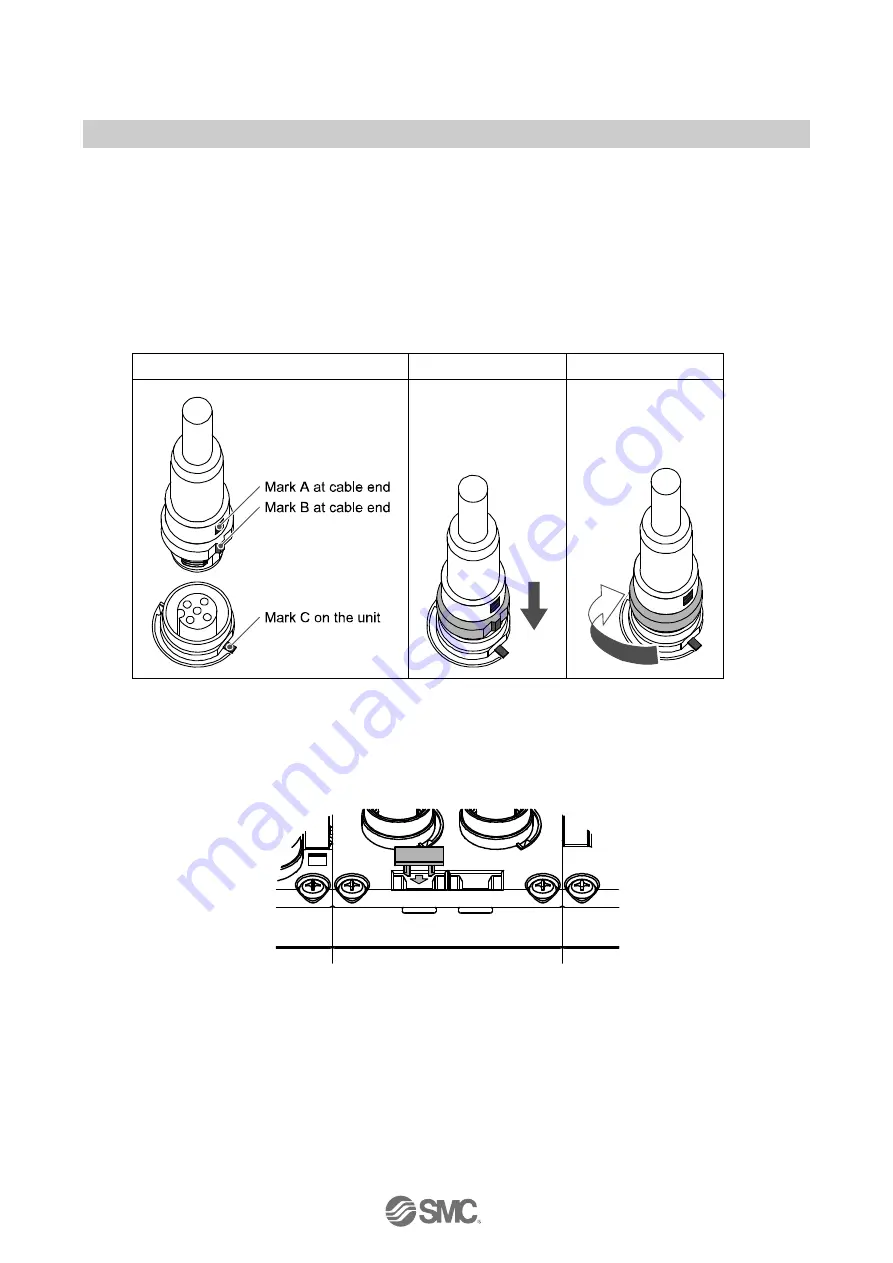

•Connect the M12 or M8 connector cable.

M12 connector is applicable for SPEEDCON connector.

SPEEDCON connector wiring method is explained

below.

(1) Align the mark B on the metal bracket of the cable side connector (plug/socket) with the mark A.

(2) Align the mark C on the unit and insert the connector into the unit vertically.

If they are not aligned, the connector cannot be joined properly.

(3) When the mark B of the connector has been turned 180 degrees (1/2 turn), wiring is completed.

Confirm that the connection is not loose. If turned too far, it will become hard to remove the connector.

(1)

(2)

(3)

•Mounting the marker

Signal name of the input or output devices and unit address can be written to the marker, and it can be

installed to each unit.

Mount the marker (EX600-ZT1) into the marker groove as required.