8

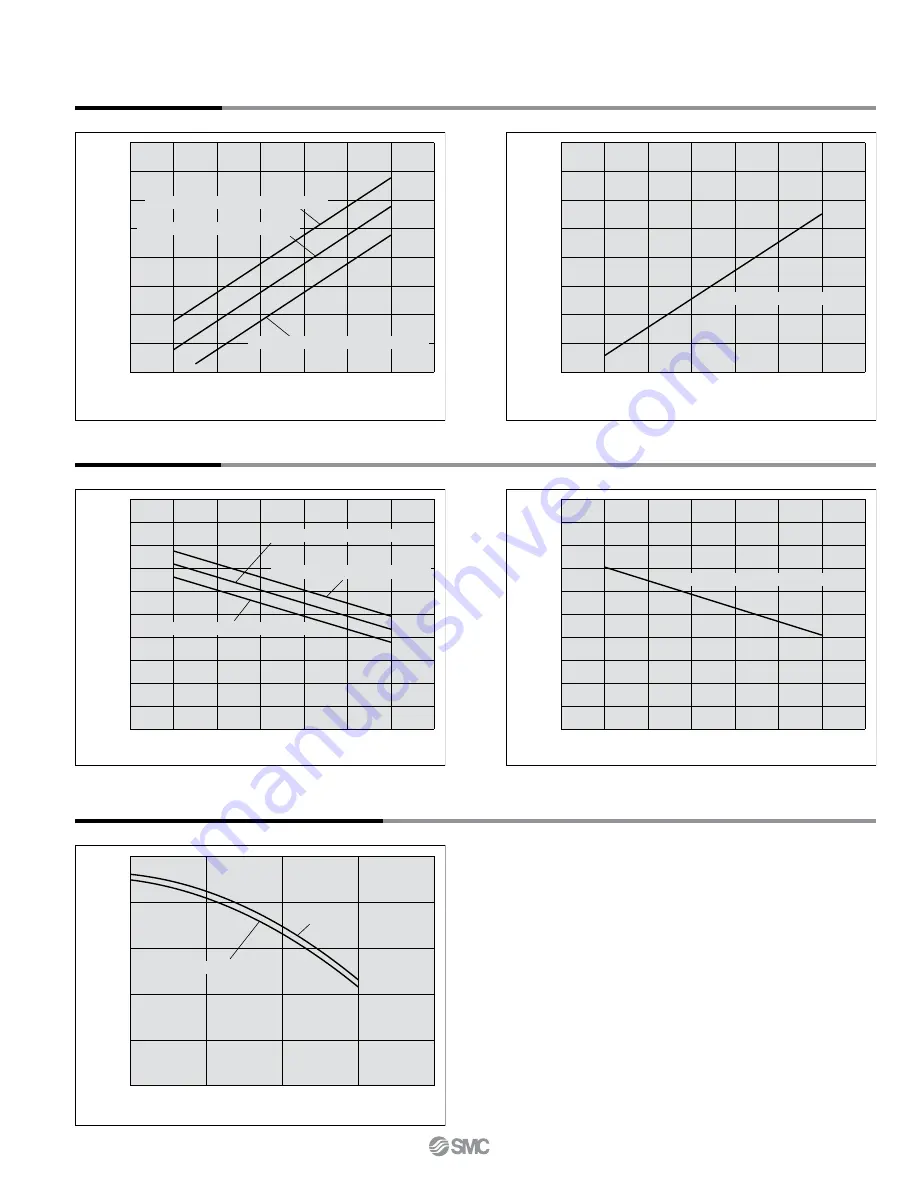

Model Selection

Series

HECR

800

700

600

500

400

300

200

100

0

0

50

[1]

68

[20]

86

[30]

104

[40]

122

[50]

140

[60]

158

[70]

Circulating fluid temperature °F [°C]

C

ooling capacity [W]

Circulating fluid: Water

Ambient temperature 59°F (15°C)

Ambient temperature 77°F (25°C)

Ambient temperature 95°F (35°F)

800

700

600

500

400

300

200

100

0

0

Circulating fluid temperature °F [°C]

C

ooling capacity [W]

Circulating fluid: Ethylene glycol 20%

Ambient temperature 77°F (25°C)

H

eating capacity [W]

1000

900

800

700

600

500

400

300

200

100

0

0

Circulating fluid: Water

Ambient temperature 59°F (15°C)

Ambient temperature 95°F (35°F)

H

eating capacity [W]

1000

900

800

700

600

500

400

300

200

100

0

0

Circulating fluid: Ethylene glycol 20%

Ambient temperature 77°F (25°C)

Circulating fluid: Water, Ethylene glycol

Circulating fluid flow rate gal/min [L/min]

Discharge pressure psi [MPa]

0.015

[0.10]

0.011

[0.08]

0

0

0.26 [1]

0.5 [2]

0.8 [3]

1.05 [4]

Ethylene glycol 20%

Water

Cooling Capacity

Pump Capacity (Thermo-con Outlet)

Heating Capacity

50

[1]

68

[20]

86

[30]

104

[40]

122

[50]

140

[60]

158

[70]

50

[1]

68

[20]

86

[30]

104

[40]

122

[50]

140

[60]

158

[70]

50

[1]

68

[20]

86

[30]

104

[40]

122

[50]

140

[60]

158

[70]

0.009

[0.06]

0.006

[0.04]

0.003

[0.02]

Ambient temperature 77°F (25°C)