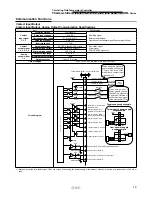

Built-in bypass circuit (

CH1: Oscillator

and

CH2: Optical system

)

(Standard)

With electric conductivity control (

CH2: Optical system

)

Particle filter set (Standard)

With casters and adjuster feet (Standard)

Removes foreign matter in

the circulating fluid

Bypass valve

CH2: Optical system

Bypass valve

CH1: Oscillator

Set control range: 0.5 to 45.0

μ

S/cm

The electric conductivity of the circulating fluid can be set with the touch panel arbitrarily.

PC

HRL

Remote

operation

switch

Output 1

Output 2

Output 3

Input 2

Input 1

User’s equipment

HRL

Outputs 4 to 6

HRL

Remote signal I/O through

serial communication

Remote operation is enabled (to start and stop

operation) through serial communication.

Alarm and operation status

(start, stop, etc.) signal output

The alarm and status generated in the product can be

output.

Remote operation signal input

One of the contact inputs is used for remote operation

and the other is used to monitor the flow of a flow

switch. This is where their alarm outputs are taken in.

Flow switch

Low flow switch

flow signal

Output examples

Output 1 : Operation status (start, stop, etc.)

Output 2 : Outputted when alarm

“FLT (operation stopped)” is generated

Output 3 : Outputted when alarm

“WRN (operation continues)” is generated

Outputs 4 to 6 : Assigned for specified type of signals

Ex. 1

Ex. 2

Ex. 3

•

Circulating fluid

temperature setting

•

Start and stop

•

Circulating fluid

discharge temperature

•

Circulating fluid discharge pressure

•

Run and stop status

•

Alarm information

•

Various setting information

•

Preparation completion status, etc.

Power for flow switches (24 VDC) can be

supplied by the thermo-chiller.

Serial communication (RS232C/RS485), contact I/Os (3 inputs and

6 outputs), and analog output (2 outputs) are equipped as standard.

This allows for communication with the user’s equipment and system

construction, depending on the application. A 24 VDC output can be also

provided and is available for use with flow switches (SMC’s PF3W, etc.).

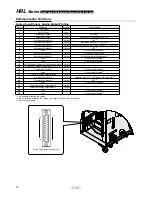

Adjuster foot

(for fixing)

Caster

(for moving)

Effective in preventing foreign

matter from entering the user’s

equipment

Set the electrical conductivity

to be set by the touch panel.

Communication functions

DI Built-in solenoid valve for control (Standard)

p. 16

Options in demand are standardized.

Communication

cable

Bypass

valve

Circulating fluid

return port

Bypass circuit

Inside of the chiller

Filter

Circulating fluid outlet

User’s

equipment

Transparent bowl

Easy to visually confirm

a dirty element

Bypass valve

Particle

filters

Fluid fill ports

Fluid level

indicators

Cable entry

Caster and

adjuster foot

Signal cable

entry

4

Circulating Fluid Temperature Controller

Thermo-chiller

Dual Channel Refrigerated Thermo-chiller for Lasers

HRL

Series