HRX-OM-T004

Chapter 5 Simple communication protocol function

5.3

Setting and checking

HRS090 Series

5-6

4.

Select serial protocol from the table below with [

▲] key or [▼] key, and confirm by pressing

“SEL”.

Table 5.3-3

List of set values

Set values

Explanation

Initial value

(Default setting)

MODBUS protocol

○

Simple communication protocol

Simple communication protocol 2

1,

2

1 :

When the setting of the contact input 2 is “Remote signal”, “Simplified

communication

protocol 2” cannot be set.

2 : Refer to chapter 2.4 for remote setting when the communication mode is SERIAL and the

simple communication protocol 2 is selected as the serial protocol.

Communication specification

Setting and checking

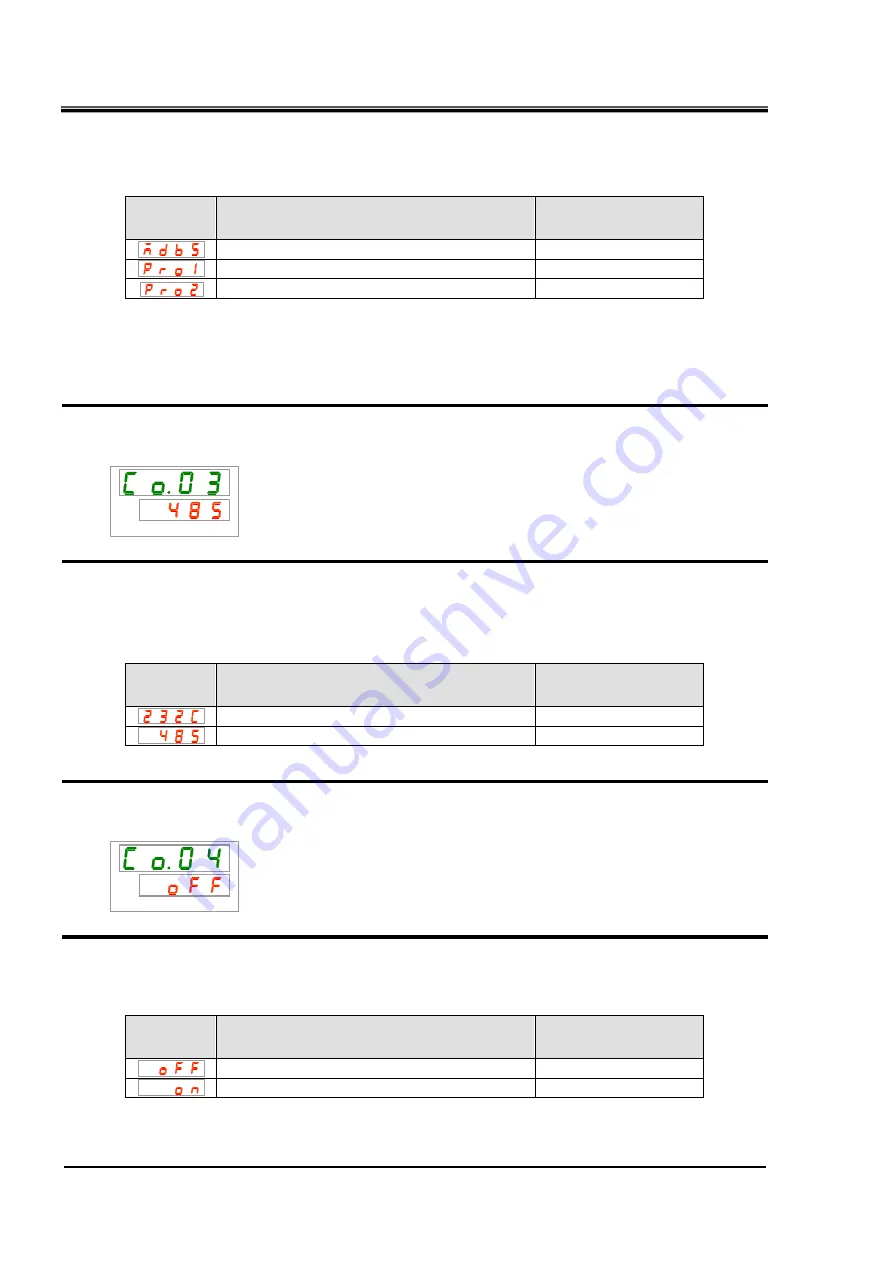

5.

Press the [SEL] key once.

The set screen of communication specification is displayed on the digital display.

6.

Select communication specification from the table below with [

▲] key or [▼] key, and

confirm by pressing “SEL”.

Table 5.3-4

List of set values

Set values

Explanation

Initial value

(Default setting)

RS-232C Standard

RS-485 Standard

○

RS-485 terminal

Setting and checking

7.

Press the [SEL] key once.

The set screen of RS-485 terminal is displayed on the digital display.

8.

Select RS-485 terminal from the table below with [

▲] key or [▼] key, and confirm by

pressing “SEL”.

Table 5.3-5

List of set values

Set values

Explanation

Initial value

(Default setting)

Without terminal

○

With terminal

PV

SV

PV

SV

Summary of Contents for HRS090 Series

Page 5: ...HRX OM T004 Contents HRS090 Series 6 3 2 Setting and checking 6 3 ...

Page 6: ......

Page 56: ......

Page 83: ......