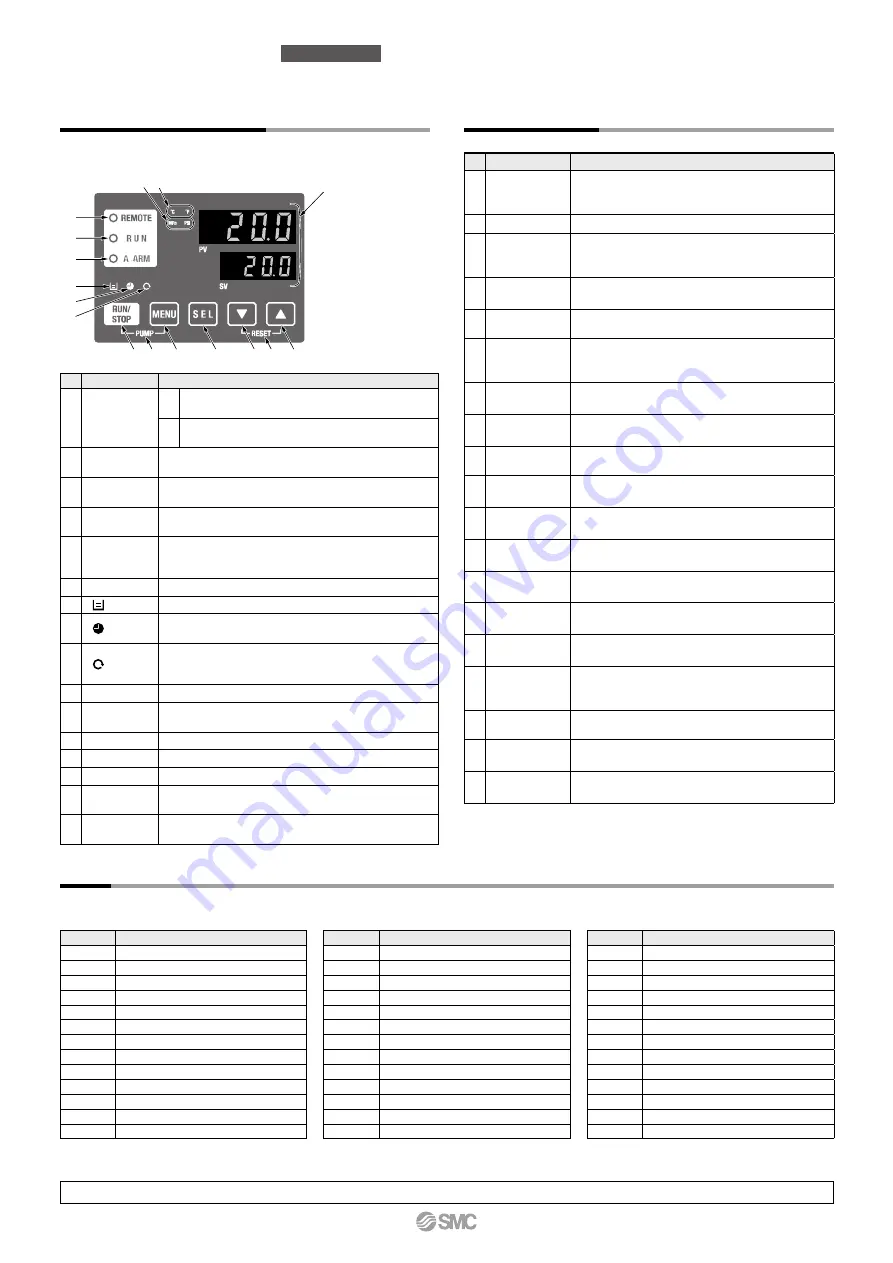

q

w

e

t

r

y

u

i

o

!0

!1

!2

!3

!4

!5

!6

Operation Display Panel

The basic operation of this unit is controlled through the

operation display panel on the front of the product.

Alarm

This unit has 39 types of alarms as standard, and displays each of them by its alarm code on the PV screen with the [ALARM] lamp ([LOW LEVEL] lamp) lit

up on the operation display panel. The alarm can be read out through communication.

Code

Alarm message

AL01

Low level in tank

AL02

High circulating fluid discharge temp.

AL03

Circulating fluid discharge temp. rise

AL04

Circulating fluid discharge temp. drop

AL05

High circulating fluid return temp.

AL08

Circulating fluid discharge pressure rise

AL09

Circulating fluid discharge pressure drop

AL10

High compressor intake temp.

AL11

Low compressor intake temp.

AL12

Low super heat temp.

AL13

High compressor discharge pressure

AL15

Refrigeration circuit pressure (high pressure side) drop

AL16

Refrigeration circuit pressure (low pressure side) rise

Code

Alarm message

AL17

Refrigeration circuit pressure (low pressure side) drop

AL18

Compressor running failure

AL19

Communication error

AL20

Memory error

AL21

DC line fuse cut

AL22

Circulating fluid discharge temp. sensor failure

AL23

Circulating fluid return temp. sensor failure

AL24

Compressor intake temp. sensor failure

AL25

Circulating fluid discharge pressure sensor failure

AL26

Compressor discharge pressure sensor failure

AL27

Compressor intake pressure sensor failure

AL28

Pump maintenance

AL29

Fan maintenance

List of Function

Code

Alarm message

AL30

Compressor maintenance

AL31

Contact input 1 signal detection

AL32

Contact input 2 signal detection

AL37

Compressor discharge temp. sensor failure

AL38

Compressor discharge temp. rise

AL40

Dustproof filter maintenance

AL41

Power stoppage

AL42

Compressor waiting

AL43

Fan failure

AL45

Compressor over current

AL47

Pump over current

AL50

Incorrect phase error

AL51

Phase board over current

No.

Description

Function

q

Digital display

(7-segment,

4 digits)

PV Displays the circulating fluid current discharge temperature

and pressure and alarm codes and other menu items (codes).

SV Displays the circulating fluid discharge temperature

and the set values of other menus.

w

[

°

C] [

°

F] lamp Equipped with a unit conversion function. Displays the

unit of displayed temperature (default setting:

°

C).

e

[MPa] [PSI]

lamp

Equipped with a unit conversion function. Displays the

unit of displayed pressure (default setting: MPa).

r

[REMOTE]

lamp

Enables remote operation (star t and stop) by

communication. Lights up during remote operation.

t

[RUN] lamp

Lights up when the product is started, and goes off when

it is stopped. Flashes during stand-by for stop or anti-

freezing function, or independent operation of the pump.

y

[ALARM] lamp Flashes with buzzer when alarm occurs.

u

[

] lamp

Lights up when the surface of the fluid level indicator falls below the L level.

i

[

] lamp

Equipped with a timer for start and stop. Lights up

when this function is operated.

o

[

] lamp

Equipped with a power failure auto-restart function, which

restarts the product automatically after stopped due to a

power failure. Lights up when this function is operated.

!0

[RUN/STOP] key Makes the product start or stop.

!1

[MENU] key

Shifts the main menu (display screen of circulating fluid discharge temperature

and pressure) and other menus (for monitoring and entry of set values).

!2

[SEL] key

Changes the item in menu and enters the set value.

!3

[

] key

Decreases the set value.

!4

[

] key

Increases the set value.

!5

[PUMP] key

Press the [MENU] and [RUN/STOP] keys simultaneously. The pump starts

running independently to make the product ready for start-up (release the air).

!6

[RESET] key Press the [

] and [

] keys simultaneously. The alarm

buzzer is stopped and the [ALARM] lamp is reset.

No.

Function

Outline

1 Main display

Displays the current and set temperature of the

circulating fluid, discharge pressure of the circulating

fluid. Changes the circulating fluid set temperature.

2 Alarm display menu Indicates alarm number when an alarm occurs.

3 Inspection

monitor menu

Product temperature, pressure and accumulated

operating time can be checked as daily inspection.

Use these for daily inspection.

4 Key-lock

Keys can be locked so that set values cannot be

changed by operator error.

5 Timer for operation

start/stop

Timer is used to set the operation start/stop.

6

Signal for the

completion of

preparation

A signal is output when the circulating fluid

temperature reaches the set temperature, when

using contact input/output and serial communication.

7 Offset function Use this function when there is a temperature offset between the

discharge temperature of the thermo-chiller and user’s equipment.

8 Reset after

power failure

Start operation automatically after the power supply

is turned on.

9 Key click

sound setting Operation panel key sound can be set on/off.

10 Changing

temp. unit

Temperature unit can be changed.

Centigrade (

°

C)

⇔

Fahrenheit (

°

F)

11 Changing

pressure unit

Pressure unit can be changed.

MPa

⇔

PSI

12 Data reset

Functions can be reset to the default settings

(settings when shipped from the factory).

13 Accumulation

time reset

Reset function when the pump, the fan or the compressor

is replaced. Reset the accumulated time here.

14 Anti-freezing

function

Circulating fluid is protected from freezing during winter

or at night. Set beforehand if there is a risk of freezing.

15 Warming-up

function

When circulating fluid temperature rising time at starting

needs shortening during winter or at night, set beforehand.

16

Anti-snow

coverage

function

If there will be a possibility of the snow coverage

due to the change of the installation environment

(season, weather), set beforehand.

17 Alarm buzzer

sound setting Alarm sound can be set to on/off.

18 Alarm

customizing

Operation during alarm condition and threshold

values can be changed depending on the alarm type.

19 Communication This function is used for contact input/output or

serial communication.

For details, refer to the Operation Manual. Please download it via our website, https://www.smcworld.com

3

HRS200

Series

Standard Type