Document No.ZL-OM01001

- 27 -

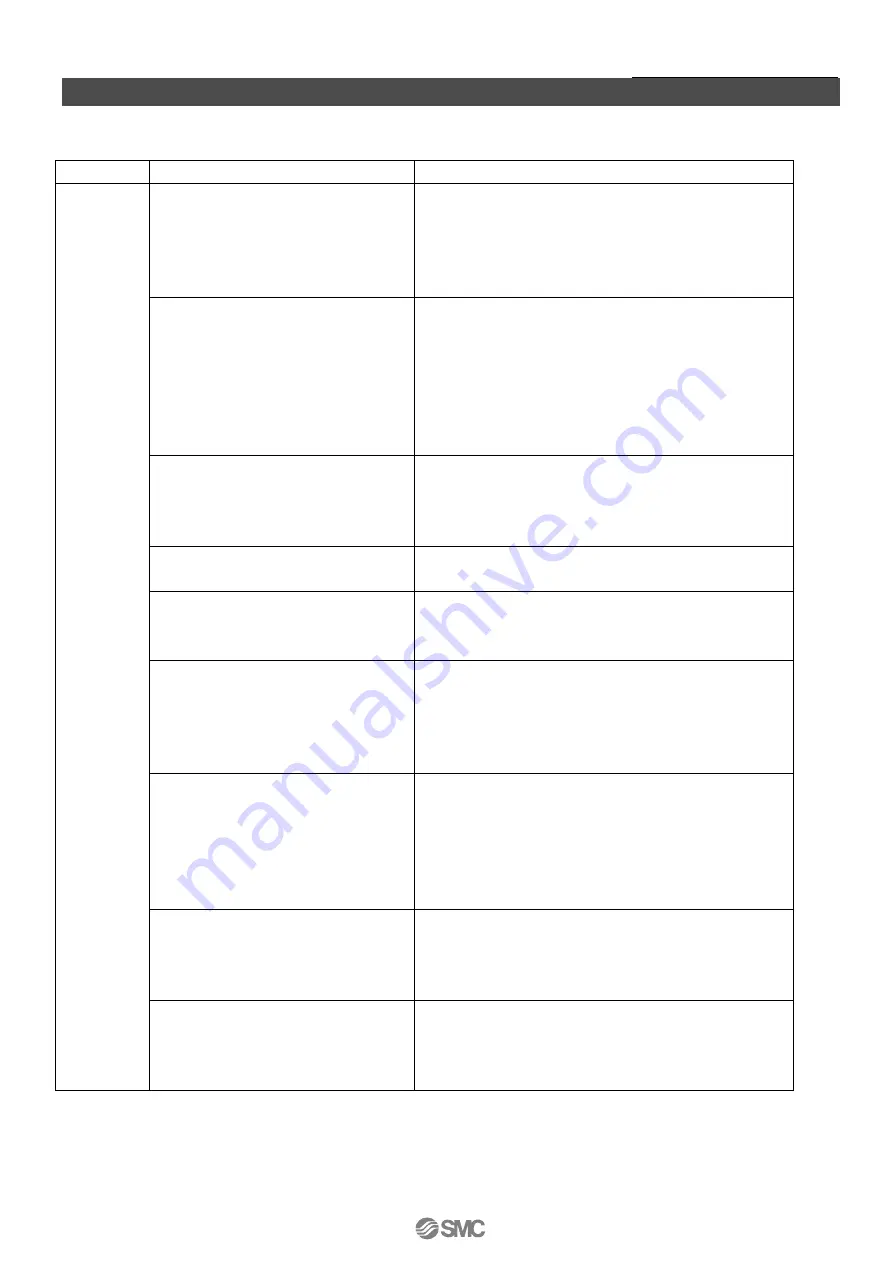

Troubleshooting

■

Problems when using ejector/ vacuum pump system and troubleshooting

Trouble

Cause

Countermeasures

Initial

adsorption

failure

(It fails to

adsorb

during the

trial run.)

The adsorption area is too small;

the adsorption force is not strong

enough compared with the weight

of the work piece and the force

applied during transfer.

Increase the lifting force.

→ Increase the pad diameter

→ Increase the number of pads.

Vacuum pressure is too small, due

to leakage at the adsorption part or

generation of a space between the

pad and the work piece due to

deformation of the work piece.

Reduce the vacuum leakage (by increasing the

vacuum pressure).

→ Change the pad configuration. Increase the

adsorption area.

→ Change the pad material (e.g. to a material that

fits the uneven surface).

→ If the workpiece is thin, change to a suitable pad.

Vacuum pressure is too small, due

to leakage of vacuum pressure

because of permeability of the work

piece.

Check the vacuum pressure and the suction flow.

→ Change to an ejector with larger suction flow.

Vacuum pressure is too small due

to leakage from the vacuum piping.

→ Repair vacuum leaking part.

Suction flow is too small.

(Ejector performance is not high

enough.)

→ Change to an ejector with larger suction flow.

Suction flow is too small because

the piping diameter is too small and

the length is too long, causing

restriction of suction flow from the

ejector.

→ Increase the piping diameter and decrease

length on the vacuum side.

Vacuum pressure and/or suction

flow are too small, because supply

pressure

to

the

ejector

is

insufficient.

→ Measure the supply pressure when the vacuum

is generated, and increase the supply pressure to

the standard supply pressure. Especially when more

than one product is operated at the same time in a

manifold, the supply air can be insufficient, causing

decrease of the supply pressure

.

Vacuum pressure and/or suction

flow are too small, due to clogging

of the nozzle and the diffuser.

→ Remove foreign matter and substances sticking

to it. (Needs to be repaired.)

Perform flushing and mount an air filter on the

supply side to prevent it happening again.

Supply valve malfunction.<0}

Measure the supply voltage to the solenoid valve.

→ Revise the electrical circuit, wiring and

connectors.

→ Use within the rated voltage range.