3

Pumping Technology

INSTALLATION

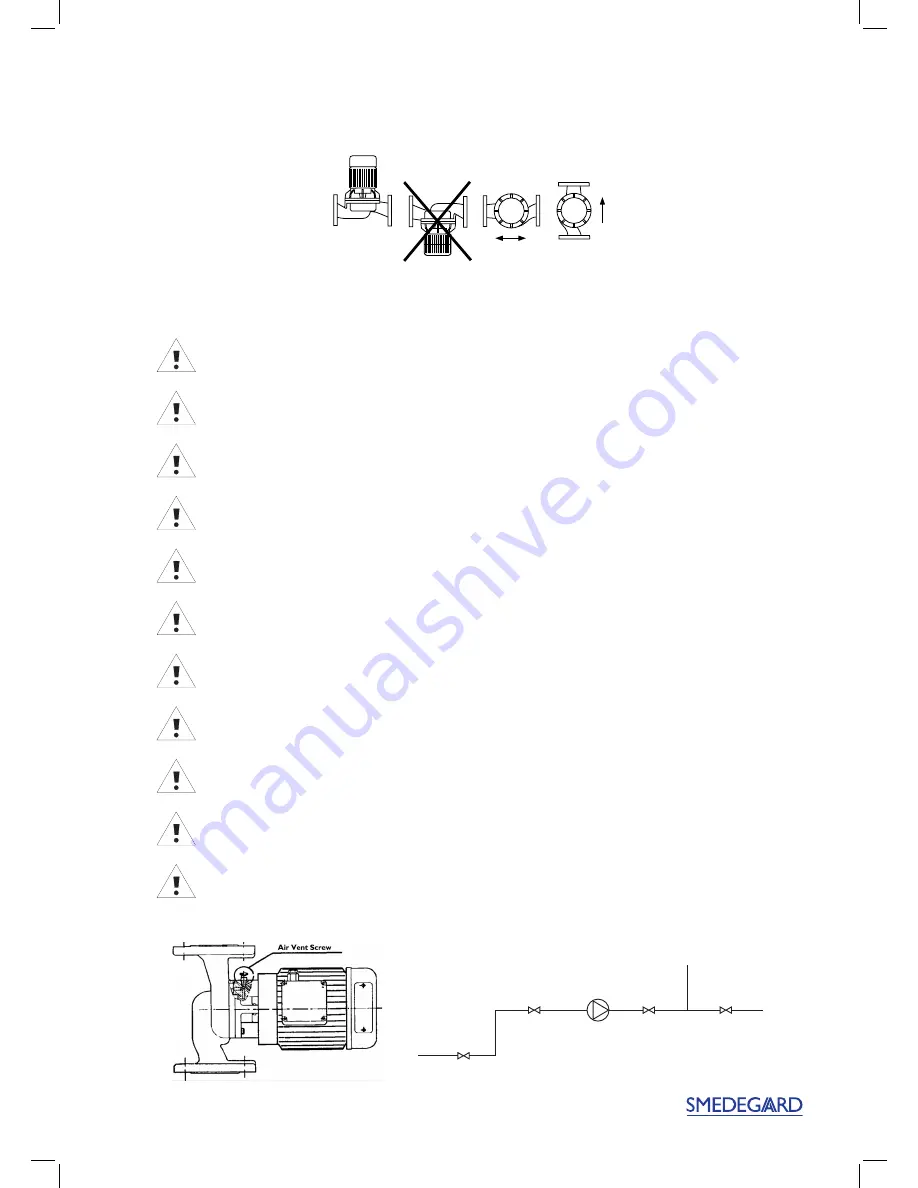

The pump can be installed with the pump shaft vertical or horizontal (see Fig.1). Direction of flow

through the pump casing is indicated by an arrow.

Fig. 1

Closed

Open

Filler Pipe

Closed

Open

Fig. 2

If the head is mounted in the horizontal position then rotate the head to ensure the air vent is at the top.

See Fig 2.

Ensure pipework alignment is correct and the pump and pipework is adequately supported. Sharp bends

should be avoided adjacent to the pump.

If pump is mounted in vertical pipework, flow should be upwards. If flow is downwards (not

recommended) it must be ensured that no air is able to collect in the pump body.

Pumps should never be allowed to operate for a long period in a closed valve condition.

To avoid accumulation of impurities in the pump, ensure that it is not mounted at the lowest point in a

system.

It is recommended that isolating valves are fitted on either side of the pump.

The system should always be thoroughly flushed out to clear any solder, steel wool, plaster or any other

foreign matter that may be lodged in the pump.

To avoid this risk of the accumulation of air within the pump body the pump should not be situated at the

highest point of the system. This may be critical in the case of HWS (bronze) pumps.

Twin headed pumps fitted into horizontal pipework and with horizontal motor shaft, then fit an automatic

air vent into the top casing.

Where provided, the threaded tappings in the base of the pump are for the attachment of a foot plate

for floor mounting and are not designed for the purpose of wall mounting. Where the pump is to be

mounted with the head in a horizontal position, the weight of the pump must be taken into consideration

so as to avoid the risk of the failure of the fixings and the consequential danger of damage or injury.