5

Pumping Technology

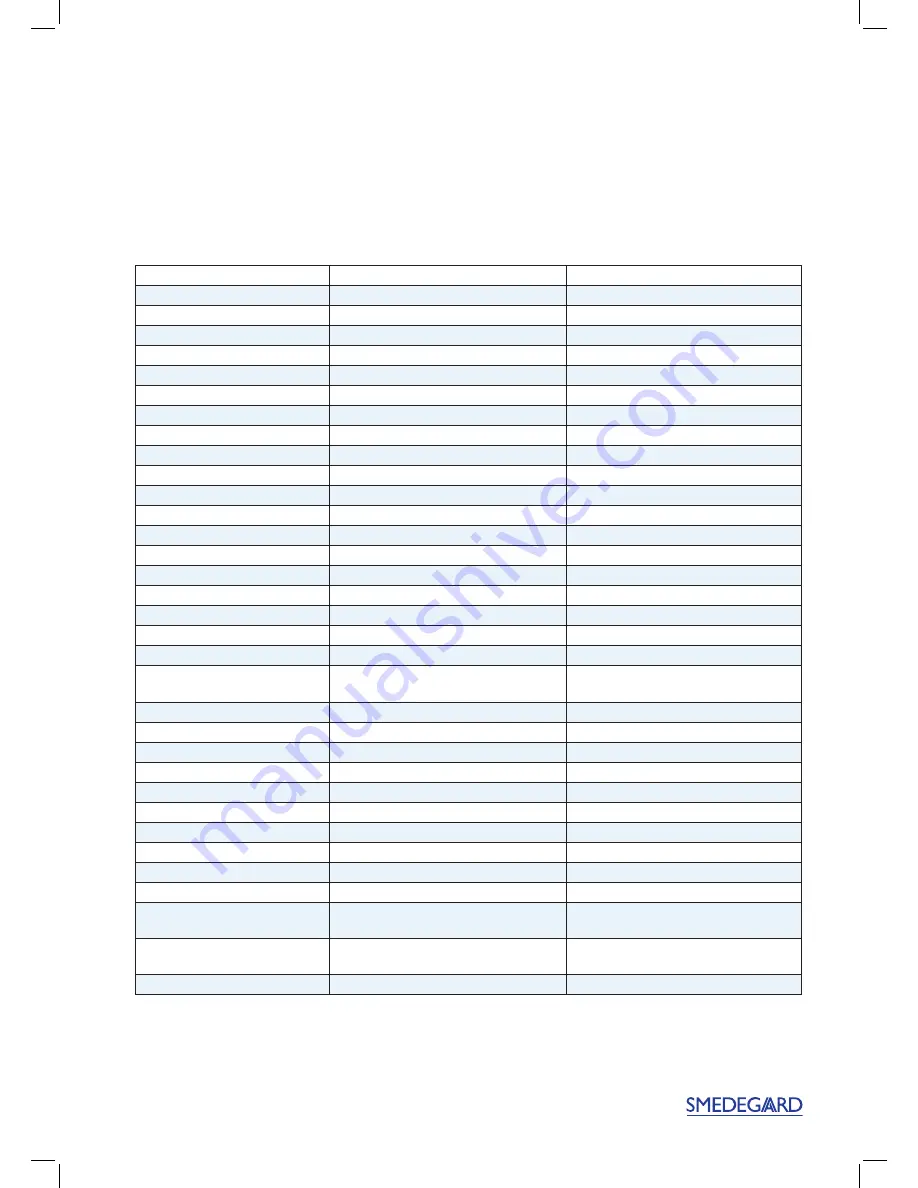

FAULT FINDING

Fault

Cause

Action

Motor does not start

Electrical supply isolated

Check motor terminals for correct voltage

Blown Fuses

Replace fuses and check current

Loose electrical connections

Tighten all electrical connections

Motor runs and then cuts out

Undersized wiring

Rewire with larger cable

Starter overload tripped

Check overload sizing with motor F.L.C

Incorrect motor links

Check motor links for star/delta

Pump failing to deliver

Not primed

Bleed pump of air

Suction valve not fully open

Open Valve

Foot valve not fully submerged (open circuits) Lower suction pipework

Air leaks in suction pipework

Recheck all joints

Wrong Rotation

Change Rotation (check wiring phases)

Foreign body in pump case

Clear obstruction

Pump leaking

Mechanical seal damaged

Replace seal

Casing “O” Ring damaged

Replace “O” ring

Pump unduly noisy

Pipework not supported correctly

Check pipe supports

Pipework causing undue strain on pump

casing

Resupport pipework or reinstall pipework

Cavitation (closed systems)

Increase static head

Cavitation (open systems)

Increase size of suction pipework

Insufficient flow

Incorrect rotation

Change rotation (check wiring phases)

Low voltage

Check Electrical supply

Air leaks in suction pipework

Recheck all joints

Valves not fully open

Open all valves

Partially clogged pump or pipework

Clear obstructions

Pump too small

Replace pump

Motor does not start but emits a

‘hum’

Foreign body in pump casing

Check motor is free to turn

1 phase motors, faulty capacitor

Pump will operate correctly if ‘spun’ but if it

fails to re-start, replace capacitor

3 phase motors, phase dropped

Check the supply phase