Installation

65

EN

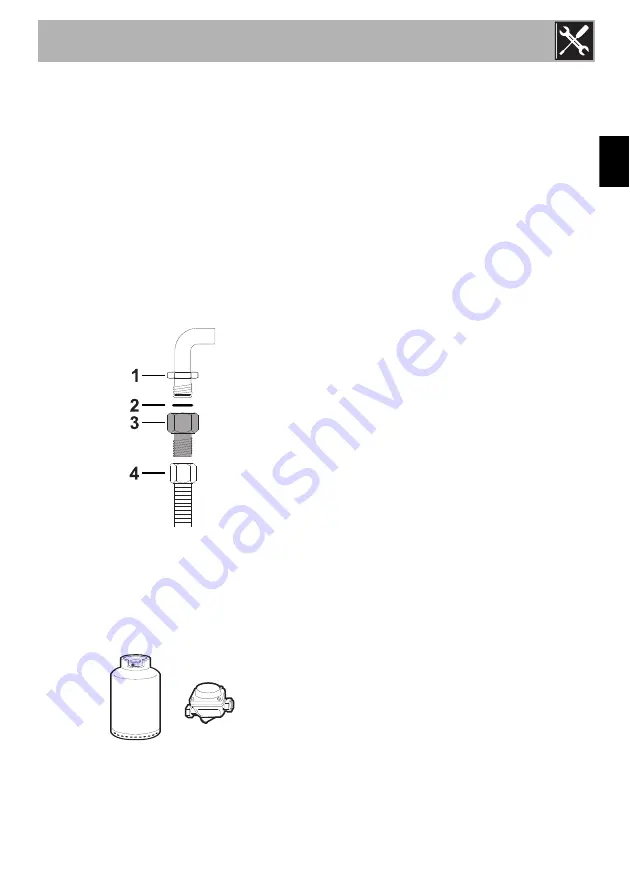

Connection with a flexible steel hose with

conical fitting

Make the connection to the gas mains

using a continuous wall flexible steel hose

whose specifications comply with the

applicable standard.

Carefully screw the hose connector

3

to the

appliance’s gas connector

1

(½” thread

ISO 228-1), placing the supplied seal

2

between them. Apply insulating material to

the thread of the connector

3

, and then

tighten the flexible steel hose

4

to the

connector

3

.

Connection to LPG

Use a pressure regulator and make the

connection on the gas cylinder following

the guidelines set out in the standards in

force.

The supply pressure must comply with the

values indicated in the table in “Gas types

and Countries”.

Room ventilation

The appliance should be installed in rooms

that have a permanent air supply in

accordance with the standards in force. The

room where the appliance is installed must

have enough air flow for the regular

combustion of gas and the necessary air

change in the room itself. The air vents,

protected by grilles, must be the right size to

comply with current regulations and

positioned so that no part of them is

obstructed, not even partially.

The room must be kept adequately

ventilated in order to eliminate the heat and

humidity produced by cooking: in

particular, after prolonged use, you are

recommended to open a window or to

increase the speed of any fans.

Extraction of the combustion products

The combustion products may be extracted

by means of hoods connected to a natural

draught chimney whose efficiency is certain

or via forced extraction. An efficient

extraction system requires precision

planning by a specialist qualified in this

area and must comply with the positions

and distances indicated by the applicable

standards.