AirVerter

®

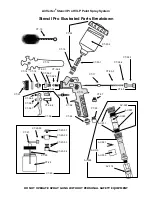

Stencil Pro HVLP Paint Spray System

DO NOT OPERATE SPRAY GUNS WITHOUT PERSONAL SAFETY EQUIPMENT

EQUIPMENT REQUIREMENTS

Air Compressor

Air compressors used with AirVerter

®

Spray Guns

must be able to HOLD a minimum of 40 PSI while

spraying.

Note

: Position a pressure gauge in

the air hose nearest the spray gun to be assured

of the PSI required to satisfactorily spray your

coating.

High Pressure Air Hose

A. Air hose lengths up to 50 feet

MUST

have an

I.D. of 3/8" including fittings.

B.

Air hose lengths greater than 50 feet

MUST

have an I.D. of 1/2" including fittings.

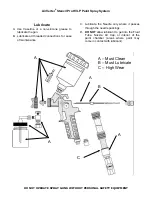

OPERATING INSTRUCTIONS

OPERATION:

Starting:

A. The Stencil Pro CT-100 Spray Gun operates

with the trigger controlling both the fluid flow

and air flow. The Stencil Pro Spray Gun may

be used with either an AirVerter

®

Inductor

Assembly between the gun and the

compressed air supply, or connected directly

to the compressed air supply.

Note: if

connecting directly to the air supply, gun inlet

pressure is limited to 43 PSI.

B.

Consult the

Needle, Nozzle and Air Cap

Selection Guide

to select the proper

combination for the coating and finish

quality desired.

Too much pressure will

create unnecessary overspray!

Before Spraying

A.

Follow the

Air and Paint Management

Guidelines

listed on the following page.

B. Before paint is poured into the cup,

make

certain paint is properly mixed

. This is

particularly true when mixing multi-component

paints. Use a paint shaker, rotary mixer, or

paint paddle to achieve a homogeneous

mixture. (

Hint:

Split your paint into two parts;

the top will be lighter and the bottom will be

heavier. Completely stir the bottom half of the

paint and slowly add small amounts of the top

half into the heavier bottom.)

C.

Strain your paint to remove impurities

. Use

a cone strainer or a 100-mesh nylon bag or

equivalent strainer.

D.

Thin your paint

according to the

manufacturer’s specifications.

E.

Ensure needle packings are properly

adjusted

. Needle packings are preset at the

factory to proper tension. However, use and

cleaning may alter this setting. To adjust

needle packings to proper tension:

1. With gun disconnected from air and fluid

sources, pull trigger to move the needle out

of the nozzle.

2. Adjust packing nut until needle is held in

the open position by tension from the

needle packings.

3.

Loosen packing nut approximately ¼ turn or

until needle returns to closed position.

Spraying

A. Gravity forces paint from the paint container

into the fluid chamber of the gun and out

through the nozzle where the flow of

atomizing air breaks the paint stream into tiny

particles, creating the spray.

1. Needle position controls the amount of

paint flowing through the fluid nozzle.

2. Trigger action controls needle position.

3. The Fluid Control Knob (CT-05-1) at the

rear of the spray gun controls trigger action.

Turning the knob to the right reduces the

fluid flow, turning it to the left increases the

flow.

B. Adjust the pattern by turning the Pattern

Control Knob (CT-07) on the side of the Spray

Gun.

1.

Round Pattern - used to draw fine lines with

the gun close to the work, for touch-up

work, camouflage patterns and painting

surfaces in difficult to reach places distant

from the spray gun. This pattern is

achieved by turning the Pattern Control

Knob clockwise

Summary of Contents for AirVerter Stencil Pro CT-100

Page 12: ......