2

Introduction

SAFE PRACTICES

1. It is your responsibility to read this manual and all publications associated with this machine.

2. Never allow anyone to operate or service the machine or its optional equipment without proper training

and instructions. Never allow minors to operate any equipment.

3. Learn the proper use of the machine, the location and purpose of all the controls and gauges before you

operate the equipment. Working with unfamiliar equipment can lead to accidents.

4. Wear all the necessary protective clothing and personal safety devises to protect your head, eyes, ears,

hands and feet. Operate the machine only in daylight or in good artificial light.

5. Inspect the area where the equipment will be used. Pick up all debris you can find before operating.

Beware of overhead obstructions and underground obstacles. Stay alert for hidden hazards.

6. Never operate equipment that is not in perfect working order or without decals, guards, shields, or other

protective devices in place.

7. Never disconnect or bypass any switch.

8. Carbon monoxide in the exhaust fumes can be fatal when inhaled, never operate a machine without

proper ventilation.

9. Fuel is highly flammable, handle with care.

10. Keep engine clean. Allow the engine to cool before storing and always remove the ignition key.

11. Disengage all drives and set park brake before starting the engine.

12. Never use your hands to search for oil leaks. Hydraulic fluid under pressure can penetrate the skin and

cause serious injury.

13. This machine demands your attention. To prevent loss of control or tipping of the vehicle:

A. Use extra caution in backing up the vehicle. Ensure area is clear.

B. Do not stop or start suddenly on any slope.

C. Reduce speed on slopes and in sharp turns. Use caution when changing directions on slopes.

D. Stay alert for holes in the terrain and other hidden hazards.

14. Before leaving operator’s position:

A. Disengage all drives.

B. Set park brake.

C. Shut engine off and remove the ignition key.

D. If engine has to run to perform any maintenance keep hands, feet, clothing and all other parts of

body away from moving parts.

15. Keep hands, feet and clothing away from moving parts. Wait for all movement to stop before you clean,

adjust or service the machine.

16. Keep the area of operation clear of all bystanders.

17. Never carry passengers.

18. Stop engine before making repairs/adjustments or checking/adding oil to the crankcase.

19. Use parts and materials supplied by

Smithco

only. Do not modify any function or part.

20. Use caution when booms are down as they extend out beyond the center line of the machine.

21. The tank is a confined space, take precaution.

These machines are intended for professional maintenance on golf courses, sports turf, and any other

area maintained turf and related trails, paths and lots. No guaranty as to the suitability for any task is

expressed or implied.

Summary of Contents for 10-100-C

Page 10: ...8 Service END USER S SERVICE CHART Duplicate this page for routine use...

Page 13: ...NOTES...

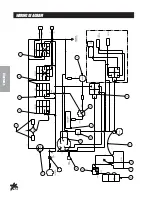

Page 14: ...12 Diagrams WIRING DIAGRAM...

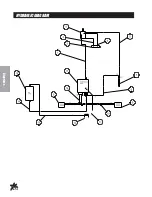

Page 16: ...14 Diagrams HYDRAULIC DIAGRAM...

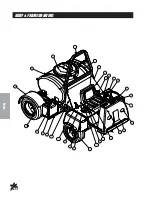

Page 18: ...16 Parts BODY FRAME DRAWING...

Page 20: ...18 Parts NOSECONEDRAWING...

Page 22: ...20 Parts FRONTAXLEDRAWING...

Page 24: ...22 Parts SEATCONSOLEANDROPSDRAWING...

Page 26: ...24 Parts FUELTANKDRAWING...

Page 28: ...26 Parts OILTANK OILFILTER OILCOOLERDRAWING...

Page 30: ...28 Parts FOOTPEDALLINKAGE DRAWING...

Page 32: ...30 Parts ENGINE PUMPSANDEXHAUSTDRAWING...

Page 34: ...32 Parts PARKBRAKEANDREARAXLEDRAWING...

Page 36: ...34 Parts TANKDRAWING TURBO QUADAGITATORDRAWING...

Page 38: ...36 Parts 15 301ORBITROLDRAWING...

Page 40: ...38 Parts 10 117 HYDRAULIC PUMP DRAWING...

Page 42: ...40 Parts 16 998HYPROPUMPDRAWING...

Page 44: ...42 Parts 10 116WHEELMOTOR 14 0 CI DRAWING...

Page 50: ...48 Accessories 16 524 MOTORIZEDCONTROLVALVEDRAWING 15 737STRAINER...

Page 52: ...50 Accessories 17 575 SMITHCOSUPERBOOM...

Page 56: ...54 Accessories 16 906ELECTRICHOSEREELDRAWING...

Page 58: ...56 Accessories 16 129MANUALHOSEREELDRAWING...

Page 60: ...58 Accessories 10 422HOSEREELMOUNT FOR17 525 17 550BOOMS...

Page 62: ...60 Accessories 1008 RAVEN 440 HOSE REEL PLUMBING DRAWING...

Page 66: ...64 Accessories 10 378FOAMMARKERFOR1000DRAWING WIRINGDRAWING...

Page 68: ...66 Accessories 10 378FOAMMARKER DRAWING...

Page 70: ...68 Accessories FOAMER NOZZLEMOUNT HOSEGUARDMOUNTDRAWING...

Page 78: ...76 Accessories 15 620CHEMICALCLEANLOAD DRAWING...