75

Accessories

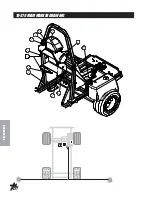

10-417 CHEMICAL CLEANLOAD

®

PART LIST

REF#

PART #

DESCRIPTION

QUANTITY

1

HB-38-16-300

Bolt

3

/

8

-16 x 3

1

HNTL-38-16

Flange Lock Nut

3

/

8

-16

1

2

15-816

Mount Bracket

1

3

HBFL-516-18-075

Flange Bolt

5

/

16

-18 x

3

/

4

4

HNFL-516-18

Flange Lock Nut

5

/

16

-18

4

4

15-620

Cleanload Eductor

1

5

18-116

Hose Clamps

4

6

16-156

90° Hose Barb

3

7

18-391

Reducer Coupling

1

8

16-972

Elbow

1

A

8897-80

Hose to Tee by Valve

1

B

8897-35

Hose to fitting on Back of Tank

1

1. Make sure all chemicals have been flushed out of spray system, as you will be disconnecting fittings from

the pump. Remember to use threaded tape on all new fitting connections.

2. Remove the 1

1

/

4

" plug from the tee on the outlet side of the

pump and install one Hose barb (16-156). Then tighten so

it points to the left side of the machine.

3. Install mounting brackets onto left side of center boom

between boom pivot and vertical boom support. Secure

with

3

/

8

x 3 bolt, flatwasher (top and bottom) and lock nut.

4. Bolt Cleanload assembly onto mounting bracket using four

flange bolts

5

/

16

-18 x

3

/

4

and flange nuts. Install 90° hose

barb (16-156) into inlet side of Cleanload (valve with yellow

handle) then tighten so it points forward and down.

5. Install one reducer coupling (18-391) and one 90° Hose

Barb (16-156) onto the outlet side of Cleanload. Tighten so

hose barb points forward and up.

6. Remove plug from top rear center of spray tank and discard. Install one hose barb (16-159) into tank fitting

and tighten.

7. Route 80" hose from the 90° hose barb on spray pump to the inlet side of the Cleanload and secure with

hose clamps (18-116).

8. Route 35" hose form 90° hose barb on outlet side on Cleanload to the hose barb on the top rear of the

tank.

9. Make sure all hardware, fittings, and clamps are tight. Add about 25 gallons of water to the spray tank.

Start Sprayer and circulate water through system and check for leaks.

10. Be sure to read start up and shutdown instructions for Cleanload assembly before using it with chemicals.

When working with chemicals always wear protective clothing, goggles and gloves.

Summary of Contents for 10-100-C

Page 10: ...8 Service END USER S SERVICE CHART Duplicate this page for routine use...

Page 13: ...NOTES...

Page 14: ...12 Diagrams WIRING DIAGRAM...

Page 16: ...14 Diagrams HYDRAULIC DIAGRAM...

Page 18: ...16 Parts BODY FRAME DRAWING...

Page 20: ...18 Parts NOSECONEDRAWING...

Page 22: ...20 Parts FRONTAXLEDRAWING...

Page 24: ...22 Parts SEATCONSOLEANDROPSDRAWING...

Page 26: ...24 Parts FUELTANKDRAWING...

Page 28: ...26 Parts OILTANK OILFILTER OILCOOLERDRAWING...

Page 30: ...28 Parts FOOTPEDALLINKAGE DRAWING...

Page 32: ...30 Parts ENGINE PUMPSANDEXHAUSTDRAWING...

Page 34: ...32 Parts PARKBRAKEANDREARAXLEDRAWING...

Page 36: ...34 Parts TANKDRAWING TURBO QUADAGITATORDRAWING...

Page 38: ...36 Parts 15 301ORBITROLDRAWING...

Page 40: ...38 Parts 10 117 HYDRAULIC PUMP DRAWING...

Page 42: ...40 Parts 16 998HYPROPUMPDRAWING...

Page 44: ...42 Parts 10 116WHEELMOTOR 14 0 CI DRAWING...

Page 50: ...48 Accessories 16 524 MOTORIZEDCONTROLVALVEDRAWING 15 737STRAINER...

Page 52: ...50 Accessories 17 575 SMITHCOSUPERBOOM...

Page 56: ...54 Accessories 16 906ELECTRICHOSEREELDRAWING...

Page 58: ...56 Accessories 16 129MANUALHOSEREELDRAWING...

Page 60: ...58 Accessories 10 422HOSEREELMOUNT FOR17 525 17 550BOOMS...

Page 62: ...60 Accessories 1008 RAVEN 440 HOSE REEL PLUMBING DRAWING...

Page 66: ...64 Accessories 10 378FOAMMARKERFOR1000DRAWING WIRINGDRAWING...

Page 68: ...66 Accessories 10 378FOAMMARKER DRAWING...

Page 70: ...68 Accessories FOAMER NOZZLEMOUNT HOSEGUARDMOUNTDRAWING...

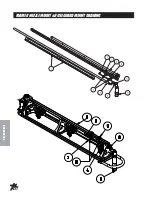

Page 78: ...76 Accessories 15 620CHEMICALCLEANLOAD DRAWING...