Summary of Contents for 10-100-D

Page 13: ...11 NOTES ...

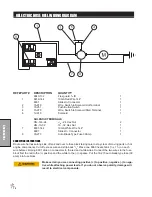

Page 14: ...12 Diagrams WIRING DIAGRAM ...

Page 16: ...14 Diagrams HYDRAULIC DIAGRAM ...

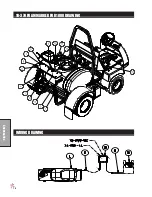

Page 18: ...16 Parts BODY FRAME DRAWING ...

Page 20: ...18 Parts NOSE CONE DRAWING ...

Page 22: ...20 Parts FRONT AXLE DRAWING ...

Page 24: ...22 Parts SEAT CONSOLE AND ROPS DRAWING ...

Page 26: ...24 Parts FUEL TANK DRAWING ...

Page 28: ...26 Parts OIL TANK OIL FILTER OIL COOLER DRAWING ...

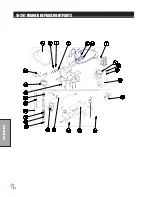

Page 30: ...28 Parts FOOT PEDAL LINKAGE DRAWING ...

Page 32: ...30 Parts PUMP DRAWING ...

Page 34: ...32 Parts ENGINE DRAWING ...

Page 36: ...34 Parts PARK BRAKE DRAWING ...

Page 38: ...36 Parts REAR AXLE DRAWING ...

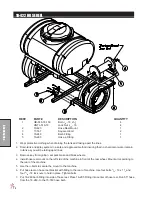

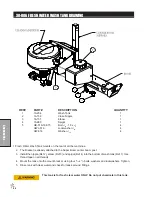

Page 40: ...38 Parts TANK DRAWING TURBO QUAD AGITATOR DRAWING ...

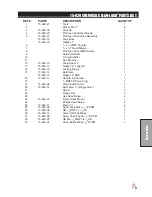

Page 42: ...40 Parts 10 576 ORBITROL DRAWING ...

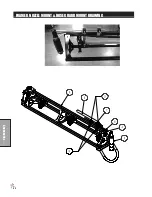

Page 56: ...54 Accessories 17 835 BOOM DRAWING ...

Page 70: ...68 Accessories 16 906 ELECTRIC HOSE REEL DRAWING ...

Page 72: ...70 Accessories 16 129 MANUAL HOSE REEL DRAWING ...

Page 78: ...76 Accessories 10 378 FOAM MARKER FOR 1000 DRAWING WIRING DRAWING ...

Page 80: ...78 Accessories 10 378 FOAM MARKER DRAWING ...

Page 82: ...80 Accessories FOAMER NOZZLE MOUNT HOSE GUARD MOUNT DRAWING ...

Page 84: ...82 Accessories 14 291 FOAMER REPLACEMENT PARTS ...

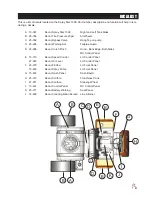

Page 90: ...88 Accessories 15 620 CHEMICAL CLEAN LOAD DRAWING ...