Summary of Contents for 10-100-F

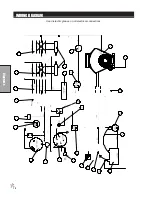

Page 12: ...10 Diagrams WIRING DIAGRAM Use dielectric grease on all electrical connections ...

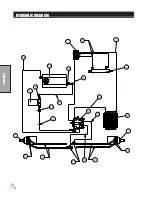

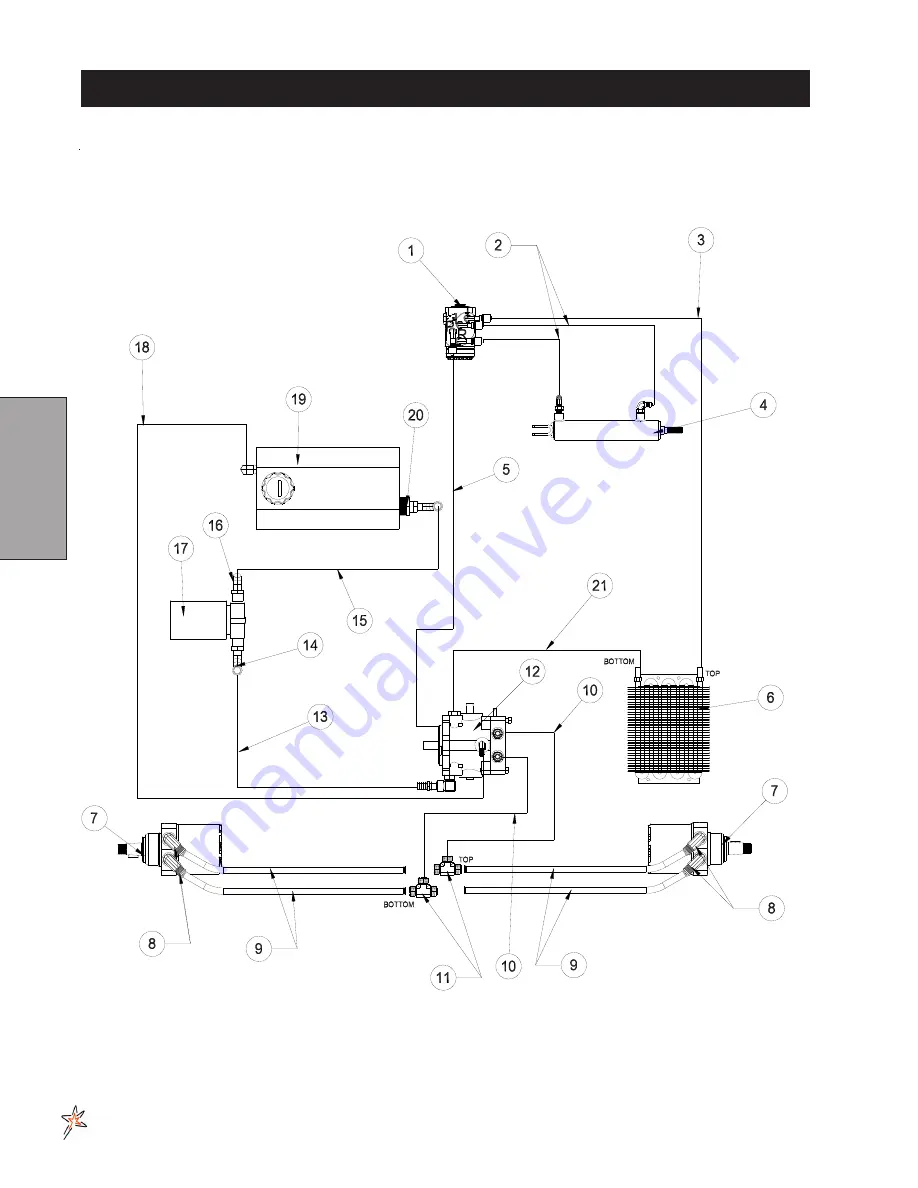

Page 14: ...12 Diagrams HYDRAULIC DIAGRAM ...

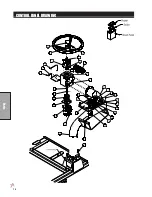

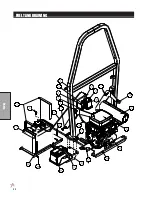

Page 16: ...14 Parts MAIN BODY DRAWING ...

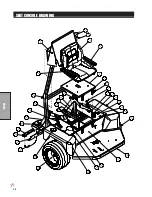

Page 18: ...16 Parts CONTROL PANEL DRAWING ...

Page 20: ...18 Parts FRONT AXLE DRAWING ...

Page 22: ...20 Parts SEAT CONSOLE DRAWING ...

Page 24: ...22 Parts FUEL TANK DRAWING ...

Page 26: ...24 Parts OIL TANK OIL FILTER OIL COOLER DRAWING ...

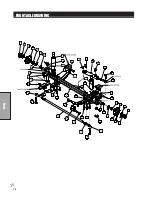

Page 28: ...26 Parts FOOT PEDAL LINKAGE DRAWING ...

Page 30: ...28 Parts PUMP DRAWING ...

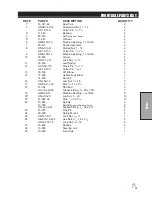

Page 32: ...30 Parts ENGINE AND SPRAY PUMP DRAWING ...

Page 34: ...32 Parts PARK BRAKE DRAWING ...

Page 36: ...34 Parts REAR AXLE DRAWING ...

Page 38: ...36 Parts TANK DRAWING TURBO QUAD AGITATOR DRAWING ...

Page 40: ...38 Parts 15 301 ORBITAL DRAWING ...

Page 42: ...40 Parts 45 373 DDC20 PISTON PUMP DRAWING ...

Page 54: ...52 Accessories CONTROL MOUNTS ...

Page 61: ...59 Accessories STAR COMMAND I WIRING 10 716 M ...

Page 66: ...64 Accessories 10 648 3 WAY MANUAL VALVE DRAWING ...

Page 71: ...69 Accessories NOTES ...

Page 72: ...70 Accessories 17 585 18 HD BOOM DRAWING ...

Page 74: ...72 Accessories 17 585 18 HD BOOM DRAWING ...

Page 80: ...78 Accessories 17 601 15 HD BOOM DRAWING ...

Page 82: ...80 Accessories 17 601 15 HD BOOM DRAWING ...

Page 92: ...90 Accessories 16 906 ELECTRIC HOSE REEL DRAWING ...

Page 104: ...102 Accessories FOAMER NOZZLE MOUNT DRAWING ...

Page 106: ...104 Accessories 14 291 FOAMER REPLACEMENT PARTS ...

Page 112: ...110 Accessories 10 417 CHEMICAL CLEAN LOAD TROUBLE SHOOTING ...

Page 114: ...112 Accessories 15 620 CHEMICAL CLEAN LOAD DRAWING ...