81

Accessories

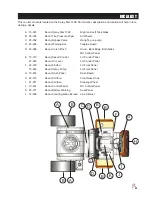

14-291 FOAMER REPLACEMENT PARTS

REF# PART#

DESCRIPTION

QUANTITY

1

14-291-01

Black Cover

1

2

14-291-08

White Fly Nut

1

3

14-291-09

Blue Fly Nut

1

4

14-284-10

Tubing Connector

1

5

14-291-17

M6 Tubing Connector

1

6

14-536

Compressor Complete

1

7

14-291-11

Diaphragm Replacement Kit

1

8

15-505-08

Brush Retainer

1

9

15-505-06

Brush

1

10

15-505-07

12V Electric Motor

1

11

15-511-02

Foam Sponge

1

12

14-284-02

Cap Assembly

1

13

14-291-02

Foamer Tank

1

14

14-291-04

Tank Brackets

2

15

15-510-01

Nozzle Mounting Rod

2

16

16-987

Foam Nozzle Mounting Kit

1

17

14-284-09

Foam Nozzle Reducer

2

18

15-511-09

Stainless Steel Screen

2

19

15-511-08

Long Foam Sponge

2

20

15-511

Foam Nozzle

2

21

15-511-07

Foam Nozzle Assembly

1

22

15-511-01

Foam Nozzle Sub Assembly

1

23

14-291-15

Shock Absorber

4

24

14-284-05

Extension Wire

1

25

14-291-05

Switch Box

1

15-506-02

Switch

1

Summary of Contents for 100684

Page 12: ...10 Diagrams WIRING DIAGRAM Use dielectric grease on all electrical connections ...

Page 14: ...12 Diagrams HYDRAULIC DIAGRAM ...

Page 16: ...14 Parts MAIN BODY DRAWING ...

Page 18: ...16 Parts CONTROL PANEL DRAWING ...

Page 20: ...18 Parts FRONT AXLE DRAWING ...

Page 22: ...20 Parts SEAT CONSOLE AND ROPS DRAWING ...

Page 24: ...22 Parts FUEL TANK DRAWING ...

Page 26: ...24 Parts OIL TANK OIL FILTER OIL COOLER DRAWING ...

Page 28: ...26 Parts FOOT PEDAL LINKAGE DRAWING ...

Page 30: ...28 Parts PUMP DRAWING ...

Page 32: ...30 Parts ENGINE AND SPRAY PUMP DRAWING ...

Page 34: ...32 Parts PARK BRAKE DRAWING ...

Page 36: ...34 Parts REAR AXLE DRAWING ...

Page 38: ...36 Parts TANK DRAWING TURBO QUAD AGITATOR DRAWING ...

Page 40: ...38 Parts 15 301 ORBITROL DRAWING ...

Page 42: ...40 Parts 45 373 DDC20 PISTON PUMP DRAWING ...

Page 53: ...51 Accessories NOTES ...

Page 54: ...52 Accessories 17 835 BOOM DRAWING ...

Page 65: ...63 Accessories NOTES ...

Page 68: ...66 Accessories 16 906 ELECTRIC HOSE REEL DRAWING ...

Page 70: ...68 Accessories 16 129 MANUAL HOSE REEL DRAWING ...

Page 80: ...78 Accessories FOAMER NOZZLE MOUNT HOSE GUARD MOUNT DRAWING ...

Page 82: ...80 Accessories 14 291 FOAMER REPLACEMENT PARTS ...

Page 88: ...86 Accessories 15 620 CHEMICAL CLEAN LOAD DRAWING ...