9

Service

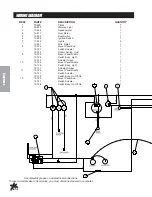

WHEEL CREEP

WHEEL CREEP

"Creep" is when the engine is running and hydrostatic transmission is in neutral, but due to inadequate align-

ment, wheels still move. Do the following procedure to stop this motion.

1. Lift up and support machine so rear wheels are off the

ground and can turn freely.

2. In the engine compartment, the hydrostatic transmission is

on the left side. The shift arm (D) is under the pump and

comes out the side. The idler arm (B) has a bearing that

runs in the notch of the shift arm. Loosen bolt (A).

3. With engine running, move bearing (B) so it centers on the

shift arm (D) and 'wheel creep' stops.

4. Tighten all fasteners and test by using foot pedal linkage to

see that 'creep' is removed.

5. Turn engine off and lower machine.

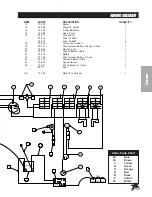

SPRAY PUMP WITH ELECTRIC CLUTCH BELT

Located to the right of the engine. Should have approximately

1

/

2

" (13mm) of deflection in the center of the top

strand. Loosen and tighten the

5

/

16

-18 x 1

1

/

4

set screw located on the foot of the pump mount.

PARK BRAKE

Turn knob clockwise on end of park brake to tighten. Turn it counter clockwise to loosen. If finer adjustment is

needed turn clevis on brake cable to adjust length of cable.

SPEED CALIBRATION NUMBERS

The speed calibration numbers for the Spray Star 1752 is 612.

STORAGE

If the engine will be out of service for two or more months, use the following storage procedure.

1. Clean the exterior surfaces of the engine.

2. Change the oil and filter while the engine is still warm from operation.

3. The fuel system must be completely emptied, or the gasoline must be treated with a stabilizer to prevent

deterioration.

If you choose to use a stabilizer, follow manufacturers recommendations, and add the correct amount for

the capacity of fuel system. Fill fuel tank with clean, fresh gasoline. Run engine for 2-3 minutes to get

stabilized fuel into carburetor. Close fuel shut-off valve when unit is being stored or transported.

To empty the system, drain fuel tank and carburetor, or run engine until tank and system are empty.

4. Remove the spark plugs. Add one tablespoon of engine oil into each spark plug hole. Install plugs, but do

not connect the plug leads. Crank the engine two or three revolutions.

5. Store machine in a clean, dry place.

Summary of Contents for 17-500

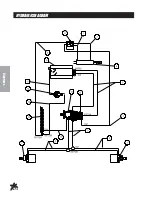

Page 14: ...12 Diagrams HYDRAULICDIAGRAM ...

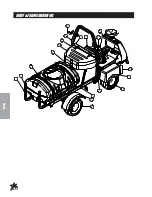

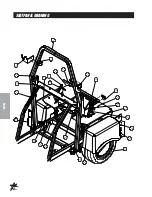

Page 16: ...14 Parts BODY FRAMEDRAWING ...

Page 18: ...16 Parts NOSE CONE DRAWING ...

Page 20: ...18 Parts NOSE CONE DRAWING ...

Page 22: ...20 Parts FRONT AXLE DRAWING ...

Page 24: ...22 Parts OILANDFUELTANKDRAWING ...

Page 26: ...24 Parts SEATPANEL DRAWING ...

Page 28: ...26 Parts ENGINE PUMPSANDEXHAUSTDRAWING ...

Page 30: ...28 Parts ENGINE PUMPSANDEXHAUSTDRAWING ...

Page 32: ...30 Parts SPRAYPUMPDRAWING ...

Page 34: ...32 Parts TANKDRAWING TURBO QUADAGITATORDRAWING ...

Page 36: ...34 Parts PARKBRAKEANDREARAXLEDRAWING ...

Page 38: ...36 Parts 15 301 ORBITROL DRAWING ...

Page 40: ...38 Parts 77 239 EATON HYDROSTATIC PUMP DRAWING DIESEL ...

Page 42: ...40 Parts 16 998 HYPRO PUMP DRAWING ...

Page 44: ...42 Accessories 1752D PLUMBING DRAWING RAVEN 440 ...

Page 46: ...44 Accessories 1754D PLUMBING DRAWING RAVEN 203 ...

Page 53: ...51 Accessories NOTES ...

Page 54: ...52 Accessories 17 503 20 SPRAY BOOM DRAWING ...

Page 56: ...54 Accessories 17 503 20 SPRAY BOOM DRAWING ...

Page 60: ...58 Accessories 15 493STAINLESSSTEEL18 AUTOBOOMDRAWING ...

Page 64: ...62 Accessories 17 525 HEAVYBOOM ...

Page 66: ...64 Accessories 17 55015 SMITHCOSUPERBOOM ...

Page 70: ...68 Accessories 16 906ELECTRICHOSEREELDRAWING ...

Page 74: ...72 Accessories 16 129MANUALHOSEREELDRAWING ...

Page 82: ...80 Accessories 17 505FOAMMARKERFOR1750DRAWING ...

Page 84: ...82 Accessories FOAMER NOZZLEMOUNT HOSEGUARDMOUNTDRAWING ...

Page 94: ...92 Accessories NOTES ...