6

Service

MAINTENANCE

TIRE PRESSURE

Caution must be used when inflating a low tire to recommended pressure. Over inflating can cause tires to ex-

plode. All tires should be 20 psi (1.4bar). Improper inflation will reduce tire life considerably.

WHEEL MOUNTING PROCEDURE

1. Set park brake. Turn machine off and remove key.

2. Block wheel on opposite corner.

3. Loosen nuts slightly on wheel to be removed.

4. Jack up machine being careful not to damage underside of machine.

5. Place wheel on hub lining up bolt holes.

6. Torque to 64-74 ft/lb (87-100Nm) using a cross pattern. Retorque after first 10 hours and every 200 hours

thereafter.

7. Lower machine to ground and remove blocks and jack.

BATTERY

Batteries normally produce explosive gases which can cause personal injury. Do not allow flames, sparks or any

ignited object to come near the battery. When charging or working near battery, always shield your eyes and

always provide proper ventilation.

Battery cable should be disconnected before using “Fast Charge”.

Charge battery at 15 amps for 10 minutes or 7 amps for 30 minutes. Do not exceed the recommended charging

rate. If electrolyte starts boiling over, decrease charging.

Always remove grounded (-) battery clamp first and replace it last. Avoid hazards by:

1. Filling batteries in well-ventilated areas.

2. Wear eye protection and rubber gloves.

3. Avoid breathing fumes when electrolyte is added.

4. Avoid spilling or dripping electrolyte.

Battery Electrolyte is an acidic solution and should be handled with care. If electrolyte is

splashed on any part of your body, flush all contact areas immediately with liberal amounts

of water. Get medical attention immediately.

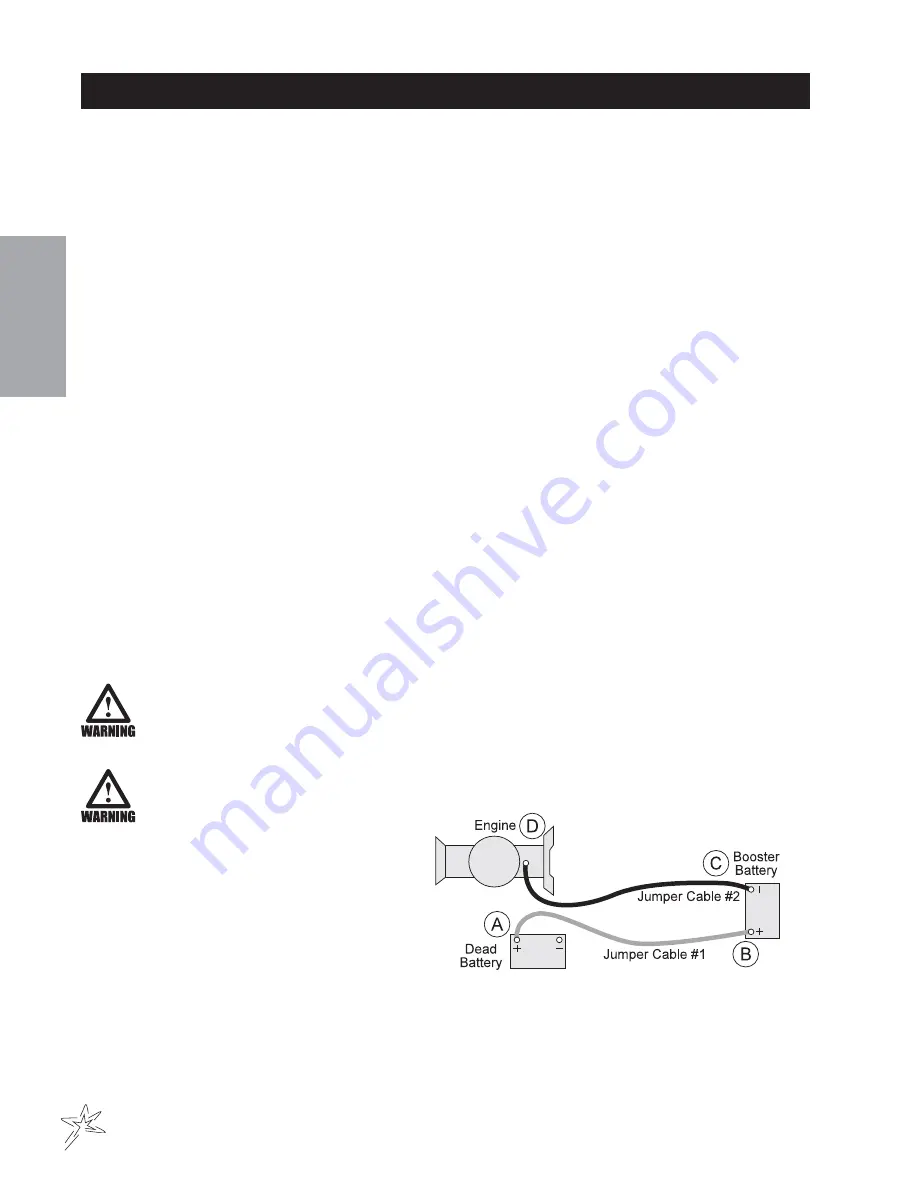

Use of booster battery and jumper

cables. Particular care should be

used when connecting a booster

battery. Use proper polarity in order

to prevent sparks.

TO JUMP START (NEGATIVE GROUNDED BATTERY):

1. Shield eyes.

2. Connect ends of one cable to positive (+)

terminals of each battery, first (A) then (B).

3. Connect one end of other cable to negative (-)

terminal of "good" battery (C).

4. Connect other end of cable (D) to engine block on unit being started (NOT to negative (-) terminal of

battery)

To prevent damage to other electrical components on unit being started, make certain that engine is at idle

speed before disconnecting jumper cables.

Summary of Contents for 175GD001

Page 14: ...12 Diagrams HYDRAULICDIAGRAM ...

Page 16: ...14 Parts BODY FRAMEDRAWING ...

Page 18: ...16 Parts NOSE CONE DRAWING ...

Page 20: ...18 Parts NOSE CONE DRAWING ...

Page 22: ...20 Parts FRONT AXLE DRAWING ...

Page 24: ...22 Parts OILANDFUELTANKDRAWING ...

Page 26: ...24 Parts SEATPANEL DRAWING ...

Page 28: ...26 Parts ENGINE PUMPSANDEXHAUSTDRAWING ...

Page 30: ...28 Parts ENGINE PUMPSANDEXHAUSTDRAWING ...

Page 32: ...30 Parts SPRAYPUMPDRAWING ...

Page 34: ...32 Parts TANKDRAWING TURBO QUADAGITATORDRAWING ...

Page 36: ...34 Parts PARKBRAKEANDREARAXLEDRAWING ...

Page 38: ...36 Parts 15 301 ORBITROL DRAWING ...

Page 40: ...38 Parts 77 239 EATON HYDROSTATIC PUMP DRAWING DIESEL ...

Page 42: ...40 Parts 16 998 HYPRO PUMP DRAWING ...

Page 44: ...42 Accessories 1752D PLUMBING DRAWING RAVEN 440 ...

Page 46: ...44 Accessories 1754DPLUMBINGDRAWING RAVEN203 ...

Page 48: ...46 Accessories CONTROLS 1752D SYSTEM DRAWING RAVEN 440 CONTROL11754DSYSTEMDRAWING RAVEN 203 ...

Page 50: ...48 Accessories 16 524 MOTORIZEDCONTROLVALVEDRAWING ...

Page 52: ...50 Accessories 15 743MSANIFOLDVALVEDRAWING ...

Page 56: ...54 Accessories 15 493STAINLESSSTEEL18 AUTOBOOMDRAWING ...

Page 58: ...56 Accessories 10 30018 TERRAINFOLLOWINGBOOMDRAWING ...

Page 60: ...58 Accessories 10 30018 TERRAINFOLLOWINGBOOMDRAWING ...

Page 62: ...60 Accessories 10 30018 TERRAINFOLLOWINGBOOMDRAWING ...

Page 64: ...62 Accessories 17 503 20 SPRAY BOOM DRAWING ...

Page 66: ...64 Accessories 17 503 20 SPRAY BOOM DRAWING ...

Page 68: ...66 Accessories 30 00320 TERRAINFOLLOWINGBOOMDRAWING ...

Page 70: ...68 Accessories 30 003 20 TERRAINFOLLOWINGBOOMDRAWING ...

Page 72: ...70 Accessories 30 003 20TERRAINFOLLOWINGBOOMDRAWING ...

Page 74: ...72 Accessories NOZZLEASSEMBLYDRAWING ...

Page 78: ...76 Accessories 17 521ELECTRICHOSEREELDRAWING ...

Page 80: ...78 Accessories ELECTRICHOSEREELWIRINGDIAGRAM ...

Page 82: ...80 Accessories 17 507HOSEREELDRAWING ...

Page 84: ...82 Accessories HOSEREELDRAWING ...

Page 86: ...84 Accessories 1752D RAVEN440 PLUMBING 1754D SSC 203 PLUMBING ...

Page 88: ...86 Accessories 17 505 FOAMMARKERFOR1750DRAWING WIRINGDRAWING ...

Page 90: ...88 Accessories 17 505FOAMMARKERFOR1750DRAWING ...

Page 92: ...90 Accessories FOAMER NOZZLEMOUNT HOSEGUARDMOUNTDRAWING ...

Page 94: ...92 Accessories FOAMMARKERDRAWING ...

Page 96: ...94 Accessories 15 505MOTORSUBASSEMBLYDRAWING ...

Page 98: ...96 Accessories 15 511FOAMNOZZLESUBASSEMBLYDRAWING ...

Page 100: ...98 Accessories 17 506FRESHWATERTANKDRAWING ...

Page 102: ...100 Accessories 14 515WATERMETERKIT GALLONS 15 618WATERMETERKIT LITERS ...

Page 104: ...102 Accessories 15 619CHEMICALCLEANLOADSAFEFILLSYSTEM ...

Page 108: ...106 Accessories NOTES ...