Accessories

109

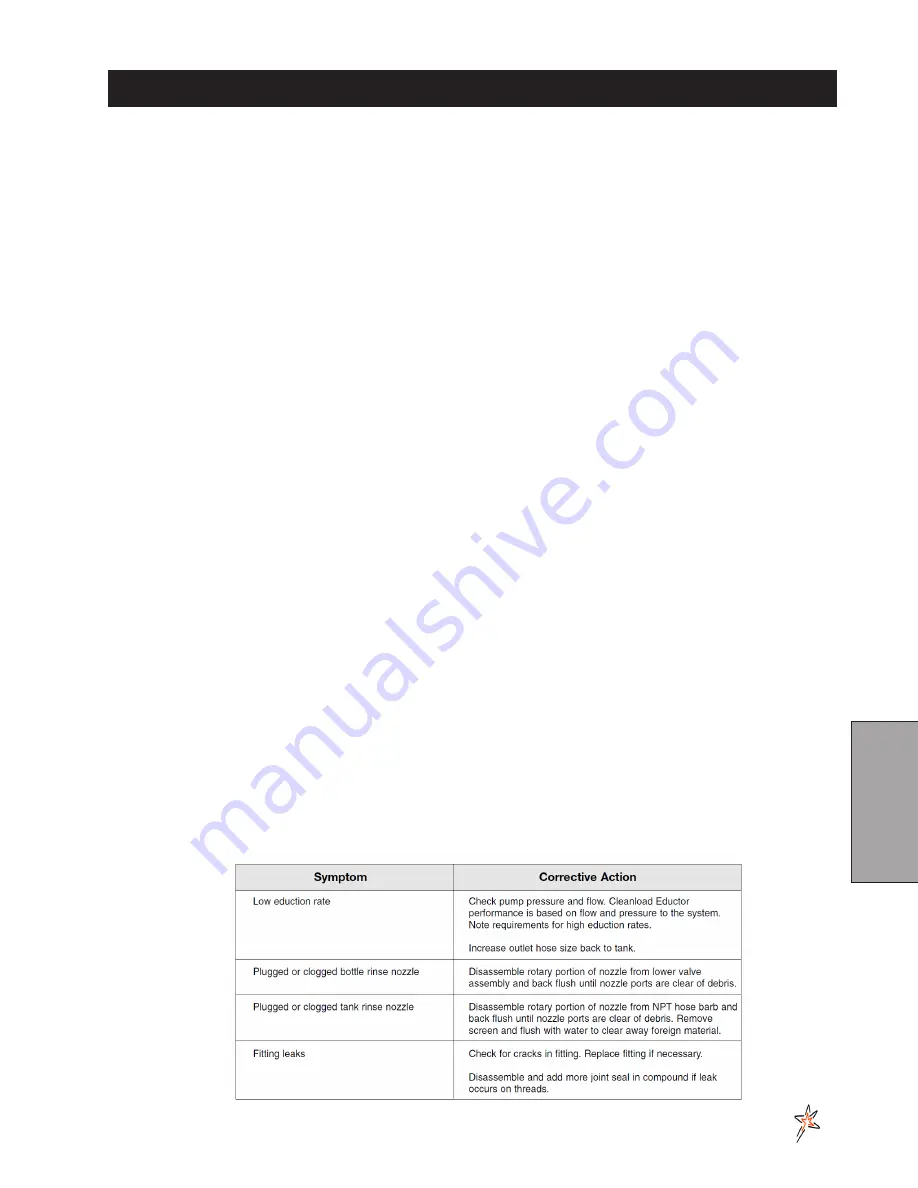

OPERATING INSTRUCTION

START-UP

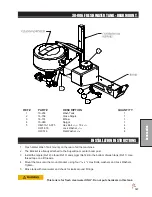

1. All Clean-load valves must be closed prior to starting: inlet ball valve, knife valve and hopper rinse ball valve.

2. Open lid to check for foreign objects which may hinder performance or contaminate the system.

3. Close and lock lid by turning cover clockwise.

4. Divert pump flow to Clean-load inlet line. A pressure of 30 PSI minimum and 150 PSI maximum must be used.

Highest pressures increase eduction rate and available wand suction.

5. Turn inlet ball valve on (yellow handle).

6. Open knife valve, located on the bottom of hopper, by pushing handle in (red handle).

7. Unlock and open lid slowly by turning cover counterclockwise.

LOADING LIQUID OR POWDERED CHEMICAL INTO HOPPER

8. Pour required amount of chemical into hopper. Avoid splashing liquids or powdered chemicals outside of hopper.

9. Rinse empty chemical containers if applicable. Place container opening over container rinse valve and press down.

This will activate the rinse valve and rinse container.

10. Rinse Clean-load hopper. Close and lock lid by turning cover clockwise. Release the safety locking band on the

hopper rinse ball valve and turn on for 20 seconds. Close ball valve and return locking band to locked position.

11. Open lid and inspect for chemical residue. Repeat step 10 as necessary.

12. Close knife valve by pulling red handle out towards you. Turn inlet (yellow handle) off.

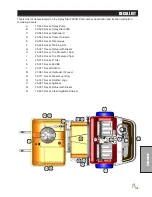

LOADING LIQUID AND/OR POWDERED CHEMICAL WITH SUCTION LANCE

Note: Lance suction is dependent upon eductor pressure and flow. For best results, use highest pressure avail

-

able up to 150 PSI maximum.

8. Insert lance body with o-ring into eductor until the o-ring is sealed.

9. Use the free end of the lance to pierce bag or container to vacuum powdered or liquid chemical.

10. Rinse lance. Place lance end into a clean container of water to rinse lance assembly.

11. Remove lance body from eductor and drain any remaining fluid into hopper.

12. Close knife valve (red handle). Turn inlet valve (yellow handle) off.

SHUTDOWN

1. Ensure that:

• All valves are closed. Be sure to close knife valve first. (Close by pulling red handle out towards you.)

• Chemical residue has been cleaned.

• Hopper lid is closed and locked by turning cover clockwise.

2. Divert pump flow back to normal operation.

Summary of Contents for 20-700-A

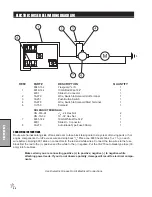

Page 16: ...14 Diagrams HYDRAULIC DIAGRAM Use dielectric grease on all electrical connections ...

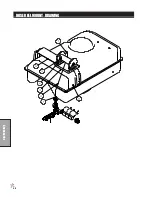

Page 18: ...16 Diagrams BODY FRAME DRAWING ...

Page 20: ...18 Parts NOSE CONE DRAWING ...

Page 22: ...20 Parts NOSE CONE DRAWING ...

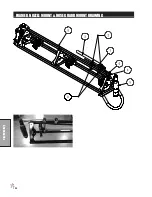

Page 24: ...22 Parts LINKAGE DRAWING ...

Page 26: ...24 Parts FRONT AXLE DRAWING ...

Page 28: ...26 Parts OIL AND FUEL TANK DRAWING ...

Page 30: ...28 Parts SEAT PANEL DRAWING ...

Page 32: ...30 Parts ENGINE AND PUMPS DRAWING ...

Page 34: ...32 Parts ENGINE AND PUMPS DRAWING ...

Page 36: ...34 Parts SPRAY PUMP DRAWING ...

Page 38: ...36 Parts REAR AXLE DRAWING ...

Page 40: ...38 Parts SPRAY TANK DRAWING ...

Page 42: ...40 Parts TURBO QUAD AGITATOR DRAWING ...

Page 44: ...42 Parts 15 301 ORBITOR DRAWING ...

Page 48: ...46 Parts 76 638 HYDROSTATIC PUMP DRAWING ...

Page 50: ...48 Parts 43 116 REAR WHEEL MOTOR DRAWING ...

Page 58: ...56 Accessories STAR COMMAND I II PLUMBING 15 818 75 Fitting O ring 15 817 50 Fitting O ring ...

Page 61: ...59 Accessories STAR COMMAND I WIRING 10 638 Fiberglass Cover 10 716 Dynajet Cover ...

Page 68: ...66 Accessories NOTES ...

Page 70: ...68 Accessories 17 580 20 HEAVY BOOM ...

Page 72: ...70 Accessories 17 580 20 BOOM DRAWING ...

Page 78: ...76 Accessories 17 585 18 HD BOOM DRAWING ...

Page 80: ...78 Accessories 17 585 18 HD BOOM DRAWING ...

Page 84: ...82 Accessories 17 601 15 HD BOOM DRAWING ...

Page 86: ...84 Accessories 17 601 15 HD BOOM DRAWING ...

Page 96: ...94 Accessories 30 010 ELECTRIC HOSE REEL DRAWING ...

Page 100: ...98 Accessories HOSE REEL MOUNT DRAWING ...

Page 102: ...100 Accessories 30 004 FOAM MARKER DRAWING WIRING DRAWING Spray Star 3180 Spray Star 2000 ...

Page 104: ...102 Accessories FOAMER NOZZLE MOUNT HOSE GUARD MOUNT DRAWING ...

Page 106: ...104 Accessories 14 291 FOAMER REPLACEMENT PARTS ...

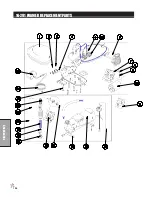

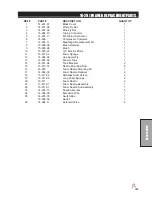

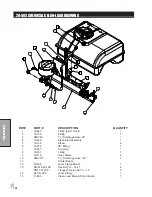

Page 112: ...110 Accessories 15 620 CHEMICAL CLEAN LOAD PARTS DRAWING ...

Page 116: ...114 Reference NOTES ...