4

Service

MAINTENANCE

Before servicing or making adjustments to machine, stop engine and remove key from ignition.

Use all procedures and parts prescribed by the manufacturer's. Read the engine manual.

LUBRICATION

Use No. 2 General purpose Lithium Base Grease and lubricate every 100 hours. The Super Star X-treme has

seven grease fittings. Two on the rake lift, one on the shift arm, one on the speed boss arm, one on the speed

boss relay, one on the attachment lift cylinder rod end adn one on the foot pedal.

AIR CLEANER ON ENGINE

1. Unhook clips on both sides of cover and remove cover.

2. Carefully slide pre-cleaner of cartridge. To service pre-cleaner, wash in liquid detergent and water. Squeeze

dry in clean cloth. Saturate in engine oil. Squeeze in clean absorbent cloth to remove excess oil. Replace

if very dirty or damaged.

3. Remove knob and plate. Carefully remove cartridge to prevent debris form entering carburetor. To service

cartridge, clean by tapping gently on flat surface. Do not oil cartridge. Replace if very dirty or damaged.

Do not use petroleum solvents, e.g.., kerosene, which will cause cartridge to deteriorate. Do

not use pressurized air to clean cartridge. Pressurized air can damage cartridge.

4. Reinstall cartridge, plate and knob.

5. Reassemble pre-cleaner on cartridge.

6. Replace cover and reattach clips to body.

REMOTE AIR CLEANER

1. Unclip the two clips, remove the cover and pull out the element.

2. To service, clean by tapping gently on flat surface. Do not oil. Replace if very dirty or damaged.

3. Clean out the inside of the body and cover.

4. Place the element into the body and put the cover back on.

TOWING

When it is necessary to move the Super Star X-treme without engine running, bypass valve built into hydrostatic

pump must be "open" by turning it counterclockwise. The valve is located on the right side of the pump. An

"open" valve allows fluid to pass through the wheels freely. When normal, driven, operation is desired, valve

should be "closed by turning it clockwise. Failure to "close" the valve with engine running means no power to

wheels. The machine can be moved for a short distance with the engine off, but we do not recommend this as a

standard procedure. When towing do not tow the machine faster than 2-3 MPH (3-5 km/h) because the drive

system may be damaged. The tires may lock up if the machine is towed too fast. If this occurs, stop towing the

machine. If the machine must be moved a considerable distance, transport it on a truck or trailer.

Summary of Contents for 43-000-B

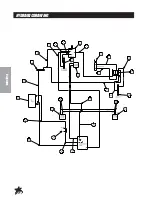

Page 16: ...14 Diagrams HYDRAULICDRAWING...

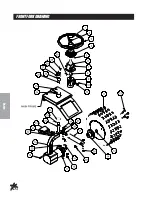

Page 18: ...16 Parts MAINFRAMECOMMONDRAWING...

Page 20: ...18 Parts FRONTFORKDRAWING...

Page 22: ...20 Parts LINKAGEDRAWING...

Page 24: ...22 Parts LINKAGEDRAWING...

Page 26: ...24 Parts GASTANKDRAWING...

Page 28: ...26 Parts OILTANKDRAWING...

Page 30: ...28 Parts ENGINEDRAWING...

Page 32: ...30 Parts ENGINEDRAWING...

Page 34: ...32 Parts Torque To 120 ft lbs 156Nm REARAXLEDRAWING...

Page 36: ...34 Parts RAKELIFTDRAWING...

Page 38: ...36 Parts 13 729 2 BANKHYDRAULICVALVEDRAWING...

Page 40: ...38 Parts 76 238FRONTWHEELMOTORDRAWING 14 5CI...

Page 42: ...40 Parts 13 615REARWHEELMOTOR 7 5C I DRAWING...

Page 44: ...42 Accessories 43 003 HYDRAULICSANDPLOWDRAWING HYDRAULICVALVEPLUMBINGDRAWING...

Page 46: ...44 Accessories 43 003 HYDRAULICSANDPLOWDRAWING HYDRAULICVALVEPLUMBINGDRAWING...

Page 48: ...46 Accessories 42 011 ABALUMINUMSANDPLOWDRAWING 42 011 SBSTEELSANDPLOWDRAWING...

Page 50: ...48 Accessories 42 13660 SANDPLOWDRAWING...

Page 52: ...50 Accessories 42 223ADJUSTABLEDISCEDGERDRAWING...

Page 54: ...52 Accessories 42 008SANDCULTIVATORDRAWING...

Page 56: ...54 Accessories 42 340SANDCULTIVATORWITHSPRINGTINESDRAWING...

Page 58: ...56 Accessories 42 341FIELDSCARIFIERWITHTINES ANDCASTORWHEELSDRAWING...

Page 60: ...58 Accessories 42 010CONSTRUCTIONLEVELINGBLADEDRAWING...

Page 62: ...60 Accessories 42 210GRADERBLADEDRAWING BLADECLIPDRAWING...

Page 64: ...62 Accessories 42 178INFIELDSCARIFIERWITHVERTICALBLADESDRAWING...

Page 66: ...64 Accessories 42 178SCARIFIERMOUNTINGDRAWING...

Page 68: ...66 Accessories 42 179INFIELDSCARIFIERWITHCHISELBLADESDRAWING...

Page 70: ...68 Accessories 42 179SCARIFIERMOUNTINGDRAWING...

Page 72: ...70 Accessories 42 285SCARIFIERWITHVERTICALBLADES...

Page 74: ...72 Accessories 42 285SCARIFIER WITHVERTICALBLADESMOUNTINGDRAWING...

Page 76: ...74 Accessories 42 02684 213CM STAINLESSSTEELTOURNAMENTRAKEDRAWING...

Page 78: ...76 Accessories 42 02684 213CM STAINLESSSTEELTOURNAMENTRAKEDRAWING...

Page 80: ...78 Accessories 42 12872 183CM STAINLESSSTEELTOURNAMENTRAKEDRAWING...

Page 82: ...80 Accessories 42 12872 183CM STAINLESSSTEELTOURNAMENTRAKEDRAWING...

Page 84: ...82 Accessories 13 438RAKEASSEMBLYWITHFINISHINGBLADESDRAWING...

Page 86: ...84 Accessories 13 684SANDRAKEBRUSHKITDRAWING HOLE LOCATION...

Page 88: ...86 Accessories 13 298FANRAKEATTACHMENTDRAWING 13 319FANRAKEKIT...

Page 90: ...88 Accessories 26 007PROFESSIONALINFIELDFINISHERDRAWING 42 185DRAGMATKITDRAWING...

Page 92: ...90 Accessories 43 002 FLEXACTIONFIELDFINISHERWITH BRUSHDRAWING...

Page 94: ...92 Accessories 43 002 FLEXACTIONFIELDFINISHERWITH BRUSHDRAWING...

Page 96: ...94 Accessories 26 008FLEXACTIONFIELDFINISHERDRAWING...

Page 98: ...96 Accessories 26 008FLEXACTIONFIELDFINISHERDRAWING...

Page 100: ...98 Accessories 43 043 FINISHINGBRUSHKITDRAWING HOLELOCATION...

Page 102: ...100 Accessories 42 582 GREEN STAR RBS SPIKER SET 3 DRAWING...

Page 104: ...102 Accessories 42 586GREENSTARRBSMAINFRAMEDRAWING...

Page 106: ...104 Reference NOTES...