15

Diagrams

HYDRAULIC PARTS LIST

REF#

PART#

DESCRIPTION

QUANTITY

1

10-187

Hydraulic Cylinder

1

14-273

Seal Kit

HCP-12-200

Clevis Pin

1

/

2

x 2

2

HP-18-100

Cotter Pin

1

/

8

x 1

2

2

73-012

Hydraulic Hose 186"

1

3

73-011

Hydraulic Hose 206"

1

4

18-169

Adapter

3

/

8

SAE

1

5

78-365

Adapter with Orfice

1

6

60-473

Oil Tank

1

13-747

Filler Breather

1

13-586-03

Neck

1

7

17-019

Male Elbow

1

8

18-190

Tee

1

9

23-142

Connector

1

10

8917-9

5

/

8

Suction Hose 9"

1

18-040

Hose Clamp

2

11

73-015

Hydraulic Hose 90"

1

12

73-017

Hydraulic Hose 53"

1

13

72-040

Hydraulic Cylinder

1

72-040-01

Seal Kit

14

23-184

Male Connector

2

15

72-075

Hydraulic Hose

1

16*

72-199

Hydraulic Motor

1

17

72-074

Hydraulic Hose

1

18

72-043

Quick Coupler

1

/

2

" Male End

2

19

72-046

Quick Coupler

1

/

2

" Female End

2

20*

78-413

Hydraulic Pump

1

21

23-006

Oil Filter

1

23-031

Replacement Filter

22

73-016

Hydraulic Hose 90"

1

23

73-013

Hydraulic Hose 118"

2

24

73-014

Hydraulic Hose 94"

1

25

78-416

Hydraulic 3-Bank Bank Valve

1

*

No other parts are replaceable for hydraulic motor or pump.

HYDRAULIC PRESSURES

Front

Rear

Pump Displacement

.90 in

3

/rev

.40 in

3

/rev

Pump Input Speed (up to)

4000 rpm

4000 rpm

Max. Operating Pressure

3600 psi

3600 psi

Max. Inlet Vacuum

10 in. Hg

10 in. Hg

Max. Case Pressure

80 psi

80 psi

Summary of Contents for 73-000-B

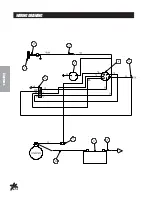

Page 14: ...12 Diagrams WIRINGDRAWING...

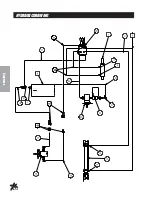

Page 16: ...14 Diagrams HYDRAULICDRAWING...

Page 18: ...16...