4

Service

MAINTENANCE

Before servicing or making adjustments to machine, stop engine and remove key from ignition.

Use all procedures and parts prescribed by the manufacturer's. Read the engine manual

before operation.

LUBRICATION

Use No. 2 General Purpose Lithium Base Grease and lubricate every 100 hours. The Sweep Star V62 has sev-

enteen grease fittings. All bearings are sealed bearings. When inserting grease, be careful not to ruin the seal, if

this happens, replace the bearing at once.

Be sure to wipe grease fitting clean before injecting grease. Give only one or two pumps of grease at each lubri-

cation.

REF#

LOCATION

1

One on all four castor wheels.

2

One on right and left hopper door arms.

3

One on each mounted bearing for reel shaft.

4

One on right and left deck lift arm.

5

one on all four castor wheel mount

brackets.

6

One on the jack stand.

7

Two on machine control panel

that go to the blower shaft

mounted bearing.

HYDRAULIC OIL

1. Use SAE 10W-40 API Service SJ or higher motor oil.

2. For proper warranty, change oil every 500 hours or annually, which ever is first and change the filter after

the first 50 hours, then every 250 hours thereafter.

3. The oil level should be 2" to 2

1

/

2

" from top of the tank when fluid is cold. Do not overfill.

4. After changing oil and/or filter, run the machine for a few minutes. Check oil level and for leaks.

5. Always use caution when filling hydraulic oil tank or checking level to keep system free of contaminants.

Check and service more frequently when operating in extremely cold, hot or dusty conditions.

6. If natural color of fluid is now black or smells burnt, it is possible that an overheating problem exists.

7. If fluid becomes milky, water contamination may be a problem.

8. If either of the above conditions happen, change oil and filter immediately after fluid is cool and find cause.

Take fluid level readings when system is cold.

9. In extreme temperatures you can use straight weight oil. We recommend SAE 30W API Service SJ or

higher when hot (above 90°F (33°C)) and SAE 10W API Service SJ or higher when cold (below 32°F (0°C))

ambient temperature. Use either motor oil or hydraulic oil, but do not mix.

10. Oil being added to the system must be the same as what is already in the tank.

Mark tank fill area as to

which type you put in.

Summary of Contents for 78-200

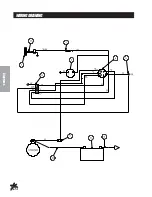

Page 14: ...12 Diagrams WIRINGDRAWING...

Page 16: ...14 Diagrams HYDRAULICDRAWING...

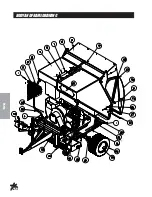

Page 18: ...16 Parts BODYANDFRAMEDRAWING...

Page 20: ...18 Parts ENGINEANDCONTROLSDRAWING...

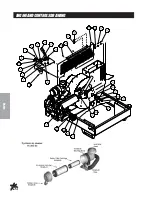

Page 22: ...20 Parts PULLEYANDPUMPDRAWING...

Page 24: ...22 Parts BLOWERANDVACUUMHOUSINGDRAWING...

Page 26: ...24 Parts FINGERREELDRAWING...

Page 28: ...26 Parts BRUSHREELDRAWING...

Page 30: ...28 Parts REEL HYDRAULICPUMPDRAWING...

Page 32: ...30 Parts HOPPERDRAWING...

Page 34: ...32 Parts HOPPERDRAWING...

Page 36: ...34 Parts 78 4152 BANKVALVEDRAWING...

Page 38: ...36 Parts REAR AXLE ELECTRIC BRAKE PARTS LIST...

Page 40: ...38 Accessories 78 201 REPLACEMENTBRUSHREELDRAWING 78 202REPLACEMENTFINGERREELDRAWING...

Page 42: ...40 Accessories 78 205REMOTEVACUUMHOSEDRAWING...

Page 44: ...42 Accessories 78 2045TH WHEELHITCHDRAWING Do not tow on public roads...

Page 46: ...44 Accessories 78 206CLEVISHITCHDRAWING...

Page 48: ...46 Accessories 78 209BALLHITCHDRAWING...

Page 50: ...48 Accessories 78 207HYDRAULICLIFTKITDRAWING...

Page 52: ...50 Accessories 78 4163 BANKHYDRAULICVALVEDRAWING...

Page 54: ...52 Accessories 78 208FILTERSYSTEMDRAWING...

Page 56: ...54 Accessories 78 210 78 211REELANDHYDRAULICPUMPDRAWING...

Page 58: ...56 Accessories 78 210NYLONBRUSHHEADDRAWING...

Page 60: ...58 Accessories 78 211RUBBERFINGERHEADDRAWING...

Page 62: ...60 NOTES...