6

Service

MAINTENANCE

(CONTINUED)

BATTERY

Batteries normally produce explosive gases which can cause personal injury. Do not allow flames, sparks or any

ignited object to come near the battery. When charging or working near battery, always shield your eyes and

always provide proper ventilation.

Battery cable should be disconnected before using “Fast Charge”.

Charge battery at 15 amps for 10 minutes or 7 amps for 30 minutes. Do not exceed the recommended charging

rate. If electrolyte starts boiling over, decrease charging.

Always remove grounded (-) battery clamp first and replace it last. Avoid hazards by:

1. Filling batteries in well-ventilated areas.

2. Wear eye protection and rubber gloves.

3. Avoid breathing fumes when electrolyte is added.

4. Avoid spilling or dripping electrolyte.

Battery Electrolyte is an acidic solution and should be handled with care. If electrolyte is

splashed on any part of your body, flush all contact areas immediately with liberal amounts

of water. Get medical attention immediately.

JUMP STARTING

Use of booster battery and jumper cables. Particular care should be used when connecting a

booster battery. Use proper polarity in order to prevent sparks.

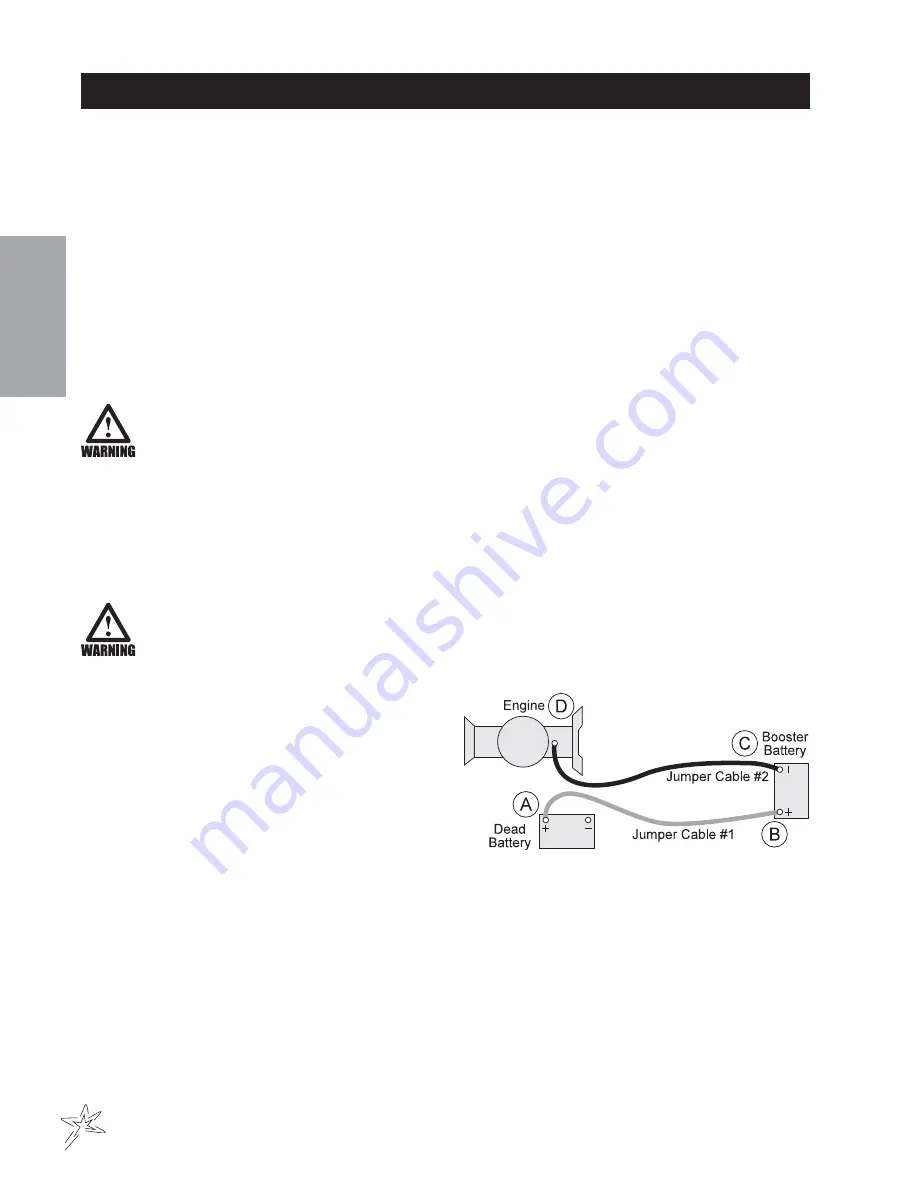

To jump start (negative grounded battery):

1. Shield eyes.

2. Connect ends of one cable to positive (+) termi-

nals of each battery, first (A) then (B).

3. Connect one end of other cable to negative (-)

terminal of "good" battery (C).

4. Connect other end of cable (D) to engine block on

unit being started (NOT to negative (-) terminal of

battery)

To prevent damage to other electrical components on

unit being started, make certain that engine is at idle speed before disconnecting jumper cables.

Summary of Contents for 78-200

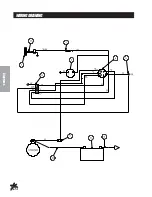

Page 14: ...12 Diagrams WIRINGDRAWING...

Page 16: ...14 Diagrams HYDRAULICDRAWING...

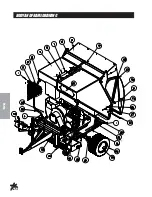

Page 18: ...16 Parts BODYANDFRAMEDRAWING...

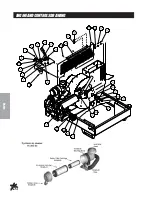

Page 20: ...18 Parts ENGINEANDCONTROLSDRAWING...

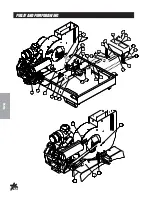

Page 22: ...20 Parts PULLEYANDPUMPDRAWING...

Page 24: ...22 Parts BLOWERANDVACUUMHOUSINGDRAWING...

Page 26: ...24 Parts FINGERREELDRAWING...

Page 28: ...26 Parts BRUSHREELDRAWING...

Page 30: ...28 Parts REEL HYDRAULICPUMPDRAWING...

Page 32: ...30 Parts HOPPERDRAWING...

Page 34: ...32 Parts HOPPERDRAWING...

Page 36: ...34 Parts 78 4152 BANKVALVEDRAWING...

Page 38: ...36 Parts REAR AXLE ELECTRIC BRAKE PARTS LIST...

Page 40: ...38 Accessories 78 201 REPLACEMENTBRUSHREELDRAWING 78 202REPLACEMENTFINGERREELDRAWING...

Page 42: ...40 Accessories 78 205REMOTEVACUUMHOSEDRAWING...

Page 44: ...42 Accessories 78 2045TH WHEELHITCHDRAWING Do not tow on public roads...

Page 46: ...44 Accessories 78 206CLEVISHITCHDRAWING...

Page 48: ...46 Accessories 78 209BALLHITCHDRAWING...

Page 50: ...48 Accessories 78 207HYDRAULICLIFTKITDRAWING...

Page 52: ...50 Accessories 78 4163 BANKHYDRAULICVALVEDRAWING...

Page 54: ...52 Accessories 78 208FILTERSYSTEMDRAWING...

Page 56: ...54 Accessories 78 210 78 211REELANDHYDRAULICPUMPDRAWING...

Page 58: ...56 Accessories 78 210NYLONBRUSHHEADDRAWING...

Page 60: ...58 Accessories 78 211RUBBERFINGERHEADDRAWING...

Page 62: ...60 NOTES...