7

Ser

vice

OVERLOADING DEBRIS HOPPER AND WEAR ON VACUUM HOUSING

MAXIMUM LOAD CAPACITY

There are decals on each side of the hopper to indicate the maximum depth of aeration cores. The maximum

depth for aeration cores in the hopper is 40" (101 cm). The maximum depth of sand and dirt in hopper is 20"

(50cm).

Overloading will cause damage that is not covered by the warranty.

OVERLOADING DEBRIS HOPPER

Smithco Vacs are designed to carry the following maximum loads:

78-500 Turf Vac

860 lbs. (400 kg)

PLEASE NOTE THE FOLLOWING:

1. Loads heavier than that will damage the unit.

2. Such damage is not covered by warranty.

3. Overloading is particularly easy when collecting aerifier cores.

4. The hopper on the VAC is large in order to hold 4 cubic yards of thatch, grass clippings, leaves and

trash.

5. They

will not

hold 4 cubic yards of aerifier cores.

6. The maximum depth (in the debris hopper) of aerifier cores is:

78-500 Turf Vac

40 in. (101 cm)

VACUUM HOUSING WEAR

Smithco Vacs are fitted with a wear resistant liner in the vacuum housing. This will provide additional housing

life. Be sure the following points are explained to the user:

1. The vacuum housing and impeller must be cleaned each time the unit is used so the housing liner is

inspected daily. Only Smithco Vacs provide a clean out/inspection port for easy inspection and cleaning.

2. When bare steel is visible at any point in the housing lining, the lining must be replaced. It is expected

the liner will wear and be replaced. It is a vast improvement over competitive units with no liners.

3. Replacement of the liner or the vacuum housing due to wear is normal and is not covered by warranty.

4. Collection of aerifier cores causes extreme wear on the liner (and if unchecked, on the housing).

5. Caution users that, while Smithco Vacs do an excellent job collecting cores, the lining (and the housing)

will wear quickly in such use.

RUBBERIZED BOOT

The rubberized boot between main unit and sweeper head is subject to wear and damage from debris. Unless

defective, replacement of this boot is not covered by warranty.

Summary of Contents for 78-500

Page 14: ...12 Diagrams WIRING DRAWING ...

Page 16: ...14 Parts BODY AND FRAME DRAWING ...

Page 18: ...16 Parts ENGINE AND GUARDS DRAWING ...

Page 20: ...18 Parts TENSIONER PULLEY DRAWING ...

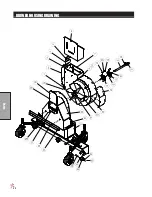

Page 22: ...20 Parts BLOWER HOUSING DRAWING ...

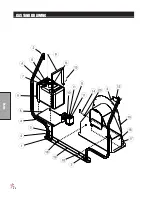

Page 24: ...22 Parts GAS TANK DRAWING ...

Page 26: ...24 Parts VACUUM HEAD DRAWING ...

Page 28: ...26 Parts HOPPER DRAWING ...

Page 30: ...28 Parts TAILGATE DRAWING ...

Page 32: ...30 Parts REAR AXLE PARTS LIST ...