8

Maintenance

MAINTENANCE

Before servicing or making adjustments to machine, stop engine on tow vehicle and remove key

from ignition. Securely prop Aer-8 on jack stands.

Use all procedures and parts prescribed by the manufacturer.

Before operating this machine, become familiar with all controls and functions of this unit and the tow vehicle.

Also complete all maintenance requirements and read all safety warnings. By knowing both machines thor-

oughly, how it operates and by doing the prescribed maintenance steps, you can expect relatively trouble-free

operation for years to come.

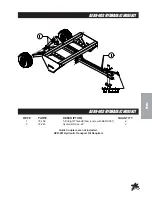

TOW VEHICLE

You will need a heavy duty vehicle with 4 wheel brakes and 3-point hitch. 3-point is standard on Aer-8 Aerifier.

Transport Frame Assembly requires a clevis hitch and a

3

/

4

diameter by 4" pin with some type of lock. Tow

vehicle must be capable of 825 lb tongue weight.

DAILY CHECKLIST

1. Check engine oil level in tow vehicle. Add as needed. DO NOT OVERFILL.

2. Check aerifier for loose or missing nuts, bolts, screws, etc., and tighten or replace as needed..

3. Check that all tines are in good condition.

4. Grease bearings daily after each use.

If transport frame assembly in installed:

5. Check hydraulic hoses for any leaks or loose connections.

6. Check tire pressure. 20 psi (1.4 bar)

7. Check electrical system for loose connections or frayed wiring, including battery cables. Replace any

faulty equipment or tighten if loose.

OPERATION SAFETY

1. Before operation check to see that reel is rotating properly.

2. 3-point lift arms of tow vehicle must not be locked, but in floating position.

3. Always lift tines completely out of the soil before making sharp turns.

4. Do not aerate during extended periods of dry periods without irrigation.

5. When not in use, remove the jack pin and extend the legs to maximum extension, reinsert the jack pin

and secure with a clip. Always use jack stands for safe storage.

LUBRICATION

Use No. 2 General Purpose Lithium Base Grease and lubricate DAILY. The Aerifier has 2 grease fittings, one

on each pillow block on each side of the reel. When inserting grease, be careful not to ruin the seal, if this hap-

pens, replace the seal at once. Be sure to wipe grease fitting clean before injecting grease. Give only one or two

pumps of grease at each lubrication.

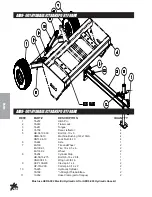

Summary of Contents for AER 8 Aerifier

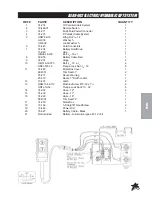

Page 16: ...14 Parts AER8 002ELECTRIC HYDRAULICLIFTSYSTEM...

Page 18: ...16 Parts...

Page 20: ...18 Parts AER 8 TURFQUAKE 5 SPACINGDRAWING...

Page 22: ...20 Parts AER 8 TURFQUAKE 7 SPACINGDRAWING...

Page 24: ...22 Parts AER 8 ALLSTAR 5 SPACINGDRAWING...

Page 26: ...24 Parts AER 8 ALLSTAR 7 SPACINGDRAWING...

Page 28: ...26 Parts AER 8 AERFINE 3 SPACINGDRAWING...

Page 30: ...28 Parts AER 8 AERFINE 5 SPACINGDRAWING...

Page 32: ...30 Parts AER 8CORINGTINESDRAWING...

Page 34: ...32 Parts REARROLLERDRAWING...