7

Maintenance

OPERATION

In excessive stony conditions reduce operating speed.

1. Attach Aer-8 to tow vehicle.

2. Fill ballast tank.

3. Check for any leaks before heading to

turf.

4. Lower Aer-8 into the ground so tine

penetrate the soil to desired depth.

5. Drive the tow vehicle at speeds that are

safe.

6. Do Not make sharp turns with the tines

in the ground. Lift Aer-8 out of the ground

when making sharp turns.

7. Compacted areas may have to be

aerated more than once.

8. When Aer-8 is not in use, remove jack

pins, extend legs to maximum exten-

sion, replace jack pins.

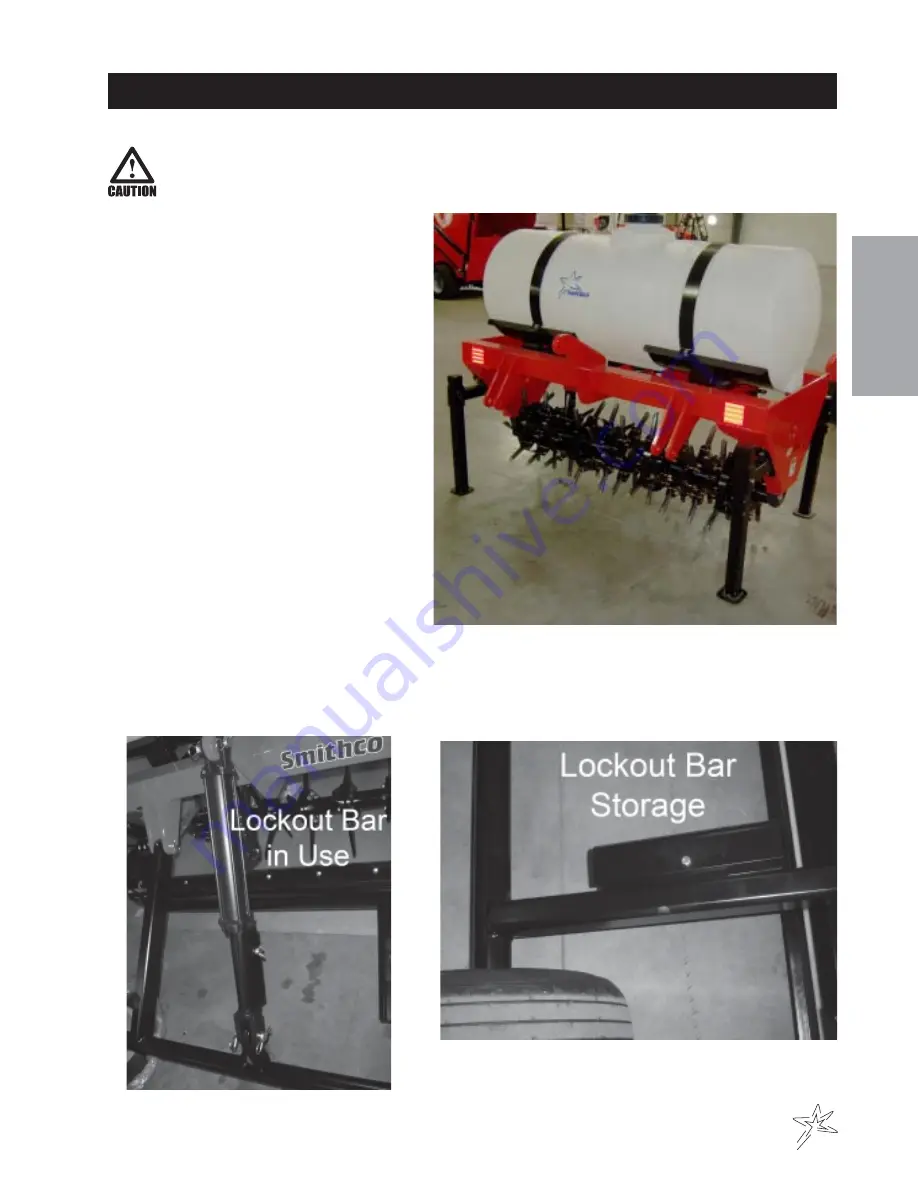

CYLINDER LOCKOUT BAR

There is a cylinder lockout attached to the rear pivot arm. This is a security guard used when the cylinder needs

to be extended for a long period of time, such as for maintenance. Placed over the cylinder rod when it is fully

extended and pin in place. When not in use return to rear pivot arm for storage.

Summary of Contents for AER 8 Series

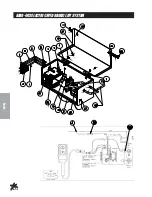

Page 16: ...14 Parts AER8 002ELECTRIC HYDRAULICLIFTSYSTEM...

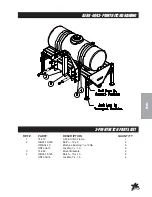

Page 18: ...16 Parts...

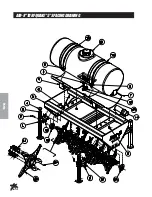

Page 20: ...18 Parts AER 8 TURFQUAKE 5 SPACINGDRAWING...

Page 22: ...20 Parts AER 8 TURFQUAKE 7 SPACINGDRAWING...

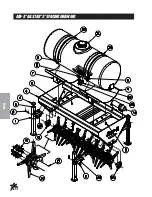

Page 24: ...22 Parts AER 8 ALLSTAR 5 SPACINGDRAWING...

Page 26: ...24 Parts AER 8 ALLSTAR 7 SPACINGDRAWING...

Page 28: ...26 Parts AER 8 AERFINE 3 SPACINGDRAWING...

Page 30: ...28 Parts AER 8 AERFINE 5 SPACINGDRAWING...

Page 32: ...30 Parts AER 8CORINGTINESDRAWING...

Page 34: ...32 Parts REARROLLERDRAWING...