Summary of Contents for Spray Star 3180

Page 11: ...9 Service END USER SERVICE CHART Duplicate this page for routine use...

Page 13: ...11 Service NOTES E...

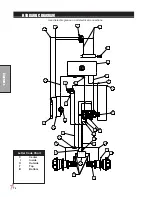

Page 18: ...16 Diagrams BODY FRAME DRAWING...

Page 20: ...18 Parts NOSE CONE DRAWING...

Page 22: ...20 Parts NOSE CONE DRAWING...

Page 24: ...22 Parts LINKAGE DRAWING...

Page 26: ...24 Parts FRONT AXLE DRAWING...

Page 28: ...26 Parts OIL AND FUEL TANK DRAWING...

Page 30: ...28 Parts SEAT PANEL DRAWING...

Page 32: ...30 Parts ENGINE AND PUMPS DRAWING...

Page 34: ...32 Parts ENGINE AND PUMPS DRAWING...

Page 36: ...34 Parts COOLER AND EXHAUST DRAWING...

Page 38: ...36 Parts TANK DRAWING...

Page 40: ...38 Parts TURBO QUAD AGITATOR DRAWING...

Page 42: ...40 Parts 15 301 ORBITROL DRAWING...

Page 44: ...42 Parts 16 998 HYPRO PUMP DRAWING...

Page 46: ...44 Parts 30 102 EATON PUMP DRAWING...

Page 48: ...46 Parts 30 102 EATON PUMP DRAWING...

Page 50: ...48 Parts 30 101 EATON MOTOR DRAWING...

Page 52: ...50 Parts 76 197 EATON GEAR PUMP DRAWING...

Page 54: ...52 Accessories 3182 PLUMBING DRAWING RAVEN 440...

Page 56: ...54 Accessories 3184 PLUMBING DRAWING RAVEN 203...

Page 58: ...56 Accessories 3185 3186 PLUMBING DRAWING ENVIZIO PRO II SHARP SHOOTER...

Page 60: ...58 Accessories 3187 3188 PLUMBING DRAWING RAVEN 400 SHARPSHOOTER...

Page 62: ...60 Accessories 3187 3188 PLUMBING DRAWING RAVEN 400 SHARPSHOOTER...

Page 64: ...62 Accessories CONTROLS 3182 SYSTEM DRAWING RAVEN 440...

Page 66: ...64 Accessories CONTROLS 3184 SYSTEM DRAWING RAVEN 203...

Page 68: ...66 Accessories WIRING 3185 3186 SYSTEM ENVIZIO PRO II SHARP SHOOTER...

Page 70: ...68 Accessories WIRING 3187 3188 SYSTEM RAVEN 440 SHARP SHOOTER...

Page 74: ...72 Accessories 15 743 MANIFOLD VALVE DRAWING...

Page 76: ...74 Accessories 17 580 20 HEAVY BOOM...

Page 78: ...76 Accessories 17 580 20 BOOM DRAWING...

Page 80: ...78 Accessories 17 585 18 HEAVY BOOM...

Page 82: ...80 Accessories 17 585 18 HEAVY BOOM...

Page 86: ...84 Accessories 30 010 ELECTRIC HOSE REEL DRAWING...

Page 90: ...88 Accessories HOSE REEL MOUNT DRAWING...

Page 92: ...90 Accessories 30 004 FOAM MARKER DRAWING WIRING DRAWING...

Page 94: ...92 Accessories 30 004 FOAM MARKER DRAWING...

Page 96: ...94 Accessories FOAMER NOZZLE MOUNT HOSE GUARD MOUNT DRAWING...

Page 99: ...97 Accessories NOTES...

Page 102: ...100 Accessories 30 006 FRESH WATER TANK DRAWING...

Page 106: ...104 Accessories 15 620 CHEMICAL CLEAN LOAD PARTS DRAWING...