4

Ser

vice

MAINTENANCE

Before servicing or making adjustments to machine, stop engine and remove key from igni-

tion.

Use all procedures and parts prescribed by the manufacturer's. Read the engine manual

before operation.

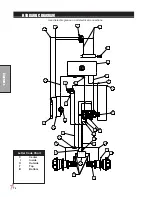

LUBRICATION

Use No. 2 General purpose lithium base grease and lubricate every 100 hours. The Spray Star 3180 has 7

grease fittings.

A. One on the rod end of hydraulic cylinder.

B. One on each the right and left spindles.

C. One on the center front pivot.

D. One on the idler arm.

E. One on each of the pedal relays.

ELECTRICAL CONNECTIONS

Use dielectric grease on all electrical connections.

AIR CLEANER ON ENGINE

Since the air cleaner on this engine is a dry type, never apply oil to it.

1. Open evacuator valve (see engine manual) once a week to remove large particles of dust and dirt.

2. Wipe the inside of the air cleaner with a cloth if it gets wet or dirty.

3. Avoid touching the element except when cleaning.

4. When dust adheres to the element, gently tap element on flat surface.

5. When carbon or oil adheres to the element clean according to engine manual.

6. Replace the element every year or every 6 months.

7. IMPORTANT - Make sure wing bolt for the element is tight enough. If it is loose, dust and dirt may be

sucked in, wearing down the cylinder liner and piston ring, resulting in poor power output.

Do not use petroleum solvents, e.g.., kerosene, which will cause cartridge to deteriorate. Do

not use pressurized air to clean cartridge. Pressurized air can damage cartridge.

FUEL

CHECK EMISSION REGULATIONS OF YOUR AREA

With Emission control now in effect diesel fuel specification type and sulfur content % (ppm) used must be in

compliant with all applicable emission regulations for the area in which the engine is operated.

Use of diesel fuel with sulfur content less than 0.10% (1000 ppm) is strongly recommended.

If high sulfur fuel is used, change oil and oil filters twice as often.

DO NOT USE Fuels that have sulfur content greater than 1.0% (10000 ppm).

Diesel fuels specified in EN 590 or ASTM D975 are recommended.

Since KUBOTA diesel engines of less than 56kW (75 hp) utilize EPA Tire 4 and Interim Tier 4 Standards, the

use of low sulfur fuel or ultra low sulfur fuel is mandatory for these engines, when operated in US EPA regu-

lated areas. Therefore, use No.2-D S500 or S15 diesel fuel as a alternative toe No. 2-D for ambient tempera-

tures below -10°C (14° F).

Summary of Contents for Spray Star 3180

Page 11: ...9 Service END USER SERVICE CHART Duplicate this page for routine use...

Page 13: ...11 Service NOTES E...

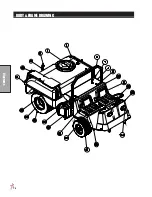

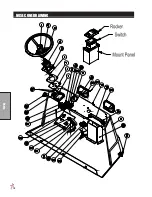

Page 18: ...16 Diagrams BODY FRAME DRAWING...

Page 20: ...18 Parts NOSE CONE DRAWING...

Page 22: ...20 Parts NOSE CONE DRAWING...

Page 24: ...22 Parts LINKAGE DRAWING...

Page 26: ...24 Parts FRONT AXLE DRAWING...

Page 28: ...26 Parts OIL AND FUEL TANK DRAWING...

Page 30: ...28 Parts SEAT PANEL DRAWING...

Page 32: ...30 Parts ENGINE AND PUMPS DRAWING...

Page 34: ...32 Parts ENGINE AND PUMPS DRAWING...

Page 36: ...34 Parts COOLER AND EXHAUST DRAWING...

Page 38: ...36 Parts TANK DRAWING...

Page 40: ...38 Parts TURBO QUAD AGITATOR DRAWING...

Page 42: ...40 Parts 15 301 ORBITROL DRAWING...

Page 44: ...42 Parts 16 998 HYPRO PUMP DRAWING...

Page 46: ...44 Parts 30 102 EATON PUMP DRAWING...

Page 48: ...46 Parts 30 102 EATON PUMP DRAWING...

Page 50: ...48 Parts 30 101 EATON MOTOR DRAWING...

Page 52: ...50 Parts 76 197 EATON GEAR PUMP DRAWING...

Page 54: ...52 Accessories 3182 PLUMBING DRAWING RAVEN 440...

Page 56: ...54 Accessories 3184 PLUMBING DRAWING RAVEN 203...

Page 58: ...56 Accessories 3185 3186 PLUMBING DRAWING ENVIZIO PRO II SHARP SHOOTER...

Page 60: ...58 Accessories 3187 3188 PLUMBING DRAWING RAVEN 400 SHARPSHOOTER...

Page 62: ...60 Accessories 3187 3188 PLUMBING DRAWING RAVEN 400 SHARPSHOOTER...

Page 64: ...62 Accessories CONTROLS 3182 SYSTEM DRAWING RAVEN 440...

Page 66: ...64 Accessories CONTROLS 3184 SYSTEM DRAWING RAVEN 203...

Page 68: ...66 Accessories WIRING 3185 3186 SYSTEM ENVIZIO PRO II SHARP SHOOTER...

Page 70: ...68 Accessories WIRING 3187 3188 SYSTEM RAVEN 440 SHARP SHOOTER...

Page 74: ...72 Accessories 15 743 MANIFOLD VALVE DRAWING...

Page 76: ...74 Accessories 17 580 20 HEAVY BOOM...

Page 78: ...76 Accessories 17 580 20 BOOM DRAWING...

Page 80: ...78 Accessories 17 585 18 HEAVY BOOM...

Page 82: ...80 Accessories 17 585 18 HEAVY BOOM...

Page 86: ...84 Accessories 30 010 ELECTRIC HOSE REEL DRAWING...

Page 90: ...88 Accessories HOSE REEL MOUNT DRAWING...

Page 92: ...90 Accessories 30 004 FOAM MARKER DRAWING WIRING DRAWING...

Page 94: ...92 Accessories 30 004 FOAM MARKER DRAWING...

Page 96: ...94 Accessories FOAMER NOZZLE MOUNT HOSE GUARD MOUNT DRAWING...

Page 99: ...97 Accessories NOTES...

Page 102: ...100 Accessories 30 006 FRESH WATER TANK DRAWING...

Page 106: ...104 Accessories 15 620 CHEMICAL CLEAN LOAD PARTS DRAWING...