5

Ser

vice

MAINTENANCE

ENGINE OIL

With strict emission control regulations now in effect, the CF-4 and CG-4 engine oils have been developed for

use with low sulfur fuels, for On-Highway vehicle engines. When Non-Road engines run on high sulfur fuel, it

is advisable to use a "CF or better" classification engine oil with Total Base Number (a minimum TBN of 10 is

recommended).

Check the engine oil before starting or more than 5 minutes after stopping the engine. If oil level is low, re-

move oil filler plug and add new oil to the prescribed level. Do not overfill. Engine oil should be MIL-L2104C

or have properties of API Classifications CD grades or higher. Change the type of Engine oil according to the

ambient temperature.

Starting Temperature Range Anticipated Before Next Oil Change

HYDRAULIC OIL

1. Use SAE 10W-40 API Service SJ or higher motor oil.

2. For proper warranty, change oil every 500 hours or annually, which ever is first.

3. Oil level should be 2-2½" (5-6.4cm) from top of the tank when fluid is cold. Do not overfill.

4. After changing oil, run the machine for a few minutes. Check oil level and for leaks.

5.

Always use extreme caution when filling hydraulic oil tank or checking level to keep system free of con

-

taminants.

Check and service more frequently when operating in extremely cold, hot or dusty conditions.

6. If the natural color of the fluid has become black or smells burnt, it is possible that an overheating prob

-

lem exists.

7. If fluid becomes milky, water contamination may be a problem.

8. If either of the above conditions happen, change oil immediately after fluid is cool and find the cause.

Take fluid level readings when the system is cold.

9. In extreme temperatures you can use straight weight oil. We recommend SAE 30W API Service SG

when hot (above 90°F (33°C)) and SAE 10W API Service SJ or higher when cold (below 32°F (0°C)

ambient temperature. Use either motor oil or hydraulic oil, but do not mix.

10. Oil being added to the system must be the same as what is already in the tank.

Mark the tank fill area

as to which type you put in.

TIRE PRESSURE

Caution must be used when inflating a low tire to recommended pressure. Over inflating can cause tires to

explode. Front tires should be 20 psi (1.4bar) and rear tires should be 30 psi (2.0bar). Improper inflation will

reduce tire life considerably.

Summary of Contents for Spray Star 3180

Page 11: ...9 Service END USER SERVICE CHART Duplicate this page for routine use...

Page 13: ...11 Service NOTES E...

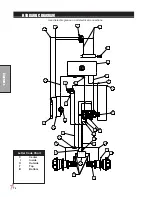

Page 18: ...16 Diagrams BODY FRAME DRAWING...

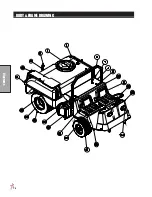

Page 20: ...18 Parts NOSE CONE DRAWING...

Page 22: ...20 Parts NOSE CONE DRAWING...

Page 24: ...22 Parts LINKAGE DRAWING...

Page 26: ...24 Parts FRONT AXLE DRAWING...

Page 28: ...26 Parts OIL AND FUEL TANK DRAWING...

Page 30: ...28 Parts SEAT PANEL DRAWING...

Page 32: ...30 Parts ENGINE AND PUMPS DRAWING...

Page 34: ...32 Parts ENGINE AND PUMPS DRAWING...

Page 36: ...34 Parts COOLER AND EXHAUST DRAWING...

Page 38: ...36 Parts TANK DRAWING...

Page 40: ...38 Parts TURBO QUAD AGITATOR DRAWING...

Page 42: ...40 Parts 15 301 ORBITROL DRAWING...

Page 44: ...42 Parts 16 998 HYPRO PUMP DRAWING...

Page 46: ...44 Parts 30 102 EATON PUMP DRAWING...

Page 48: ...46 Parts 30 102 EATON PUMP DRAWING...

Page 50: ...48 Parts 30 101 EATON MOTOR DRAWING...

Page 52: ...50 Parts 76 197 EATON GEAR PUMP DRAWING...

Page 54: ...52 Accessories 3182 PLUMBING DRAWING RAVEN 440...

Page 56: ...54 Accessories 3184 PLUMBING DRAWING RAVEN 203...

Page 58: ...56 Accessories 3185 3186 PLUMBING DRAWING ENVIZIO PRO II SHARP SHOOTER...

Page 60: ...58 Accessories 3187 3188 PLUMBING DRAWING RAVEN 400 SHARPSHOOTER...

Page 62: ...60 Accessories 3187 3188 PLUMBING DRAWING RAVEN 400 SHARPSHOOTER...

Page 64: ...62 Accessories CONTROLS 3182 SYSTEM DRAWING RAVEN 440...

Page 66: ...64 Accessories CONTROLS 3184 SYSTEM DRAWING RAVEN 203...

Page 68: ...66 Accessories WIRING 3185 3186 SYSTEM ENVIZIO PRO II SHARP SHOOTER...

Page 70: ...68 Accessories WIRING 3187 3188 SYSTEM RAVEN 440 SHARP SHOOTER...

Page 74: ...72 Accessories 15 743 MANIFOLD VALVE DRAWING...

Page 76: ...74 Accessories 17 580 20 HEAVY BOOM...

Page 78: ...76 Accessories 17 580 20 BOOM DRAWING...

Page 80: ...78 Accessories 17 585 18 HEAVY BOOM...

Page 82: ...80 Accessories 17 585 18 HEAVY BOOM...

Page 86: ...84 Accessories 30 010 ELECTRIC HOSE REEL DRAWING...

Page 90: ...88 Accessories HOSE REEL MOUNT DRAWING...

Page 92: ...90 Accessories 30 004 FOAM MARKER DRAWING WIRING DRAWING...

Page 94: ...92 Accessories 30 004 FOAM MARKER DRAWING...

Page 96: ...94 Accessories FOAMER NOZZLE MOUNT HOSE GUARD MOUNT DRAWING...

Page 99: ...97 Accessories NOTES...

Page 102: ...100 Accessories 30 006 FRESH WATER TANK DRAWING...

Page 106: ...104 Accessories 15 620 CHEMICAL CLEAN LOAD PARTS DRAWING...