6

Ser

vice

MAINTENANCE

BATTERY

Batteries normally produce explosive gases which can cause personal injury. Do not allow flames, sparks or

any ignited object to come near the battery. When charging or working near battery, always shield your eyes

and always provide proper ventilation.

Battery cable should be disconnected before using “Fast Charge”.

Charge battery at 15 amps for 10 minutes or 7 amps for 30 minutes. Do not exceed the recommended

charging rate. If electrolyte starts boiling over, decrease charging.

Always remove grounded (-) battery clamp first and replace it last. Avoid hazards by:

1. Filling batteries in well-ventilated areas.

2. Wear eye protection and rubber gloves.

3. Avoid breathing fumes when electrolyte is added.

4. Avoid spilling or dripping electrolyte.

Battery Electrolyte is an acidic solution and should be handled with care. If electrolyte is

splashed on any part of your body, flush all contact areas immediately with liberal amounts

of water. Get medical attention immediately.

Use of booster battery and jumper cables. Particular care should be used when connecting a

booster battery. Use proper polarity in order to prevent sparks.

TO JUMP START (NEGATIVE GROUNDED BATTERY):

1. Shield eyes.

2. Connect ends of one cable to positive (+) termi-

nals of each battery, first (A) then (B).

3. Connect one end of other cable to negative (-)

terminal of "good" battery (C).

4. Connect other end of cable (D) to engine block

on unit being started (NOT to negative (-) termi-

nal of battery)

To prevent damage to other electrical components on

unit being started, make certain that engine is at idle

speed before disconnecting jumper cables.

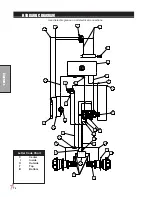

WHEEL CREEP

WHEEL CREEP

"Creep" is when the engine is running and hydrostatic transmission is in neutral,

but due to inadequate alignment, wheels still move. Do the following procedure

to stop this motion.

1. Lift up and support machine so rear wheels are off the ground and can

turn freely.

2. In the engine compartment, the hydrostatic pump is on the right side. The

shift arm (D) is on top of the pump The idler arm (B) has a bearing that

rides in the vee of the shift arm. Loosen bolt (A).

3. With engine running, move bearing (B) so it centers on the shift arm (D)

and 'wheel creep' stops.

4. Tighten all fasteners and test by using foot pedal linkage to see that

'creep' is removed.

5. Turn engine off and lower machine.

Summary of Contents for Spray Star 3180

Page 11: ...9 Service END USER SERVICE CHART Duplicate this page for routine use...

Page 13: ...11 Service NOTES E...

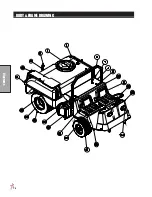

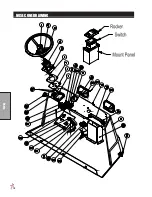

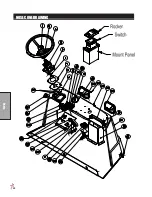

Page 18: ...16 Diagrams BODY FRAME DRAWING...

Page 20: ...18 Parts NOSE CONE DRAWING...

Page 22: ...20 Parts NOSE CONE DRAWING...

Page 24: ...22 Parts LINKAGE DRAWING...

Page 26: ...24 Parts FRONT AXLE DRAWING...

Page 28: ...26 Parts OIL AND FUEL TANK DRAWING...

Page 30: ...28 Parts SEAT PANEL DRAWING...

Page 32: ...30 Parts ENGINE AND PUMPS DRAWING...

Page 34: ...32 Parts ENGINE AND PUMPS DRAWING...

Page 36: ...34 Parts COOLER AND EXHAUST DRAWING...

Page 38: ...36 Parts TANK DRAWING...

Page 40: ...38 Parts TURBO QUAD AGITATOR DRAWING...

Page 42: ...40 Parts 15 301 ORBITROL DRAWING...

Page 44: ...42 Parts 16 998 HYPRO PUMP DRAWING...

Page 46: ...44 Parts 30 102 EATON PUMP DRAWING...

Page 48: ...46 Parts 30 102 EATON PUMP DRAWING...

Page 50: ...48 Parts 30 101 EATON MOTOR DRAWING...

Page 52: ...50 Parts 76 197 EATON GEAR PUMP DRAWING...

Page 54: ...52 Accessories 3182 PLUMBING DRAWING RAVEN 440...

Page 56: ...54 Accessories 3184 PLUMBING DRAWING RAVEN 203...

Page 58: ...56 Accessories 3185 3186 PLUMBING DRAWING ENVIZIO PRO II SHARP SHOOTER...

Page 60: ...58 Accessories 3187 3188 PLUMBING DRAWING RAVEN 400 SHARPSHOOTER...

Page 62: ...60 Accessories 3187 3188 PLUMBING DRAWING RAVEN 400 SHARPSHOOTER...

Page 64: ...62 Accessories CONTROLS 3182 SYSTEM DRAWING RAVEN 440...

Page 66: ...64 Accessories CONTROLS 3184 SYSTEM DRAWING RAVEN 203...

Page 68: ...66 Accessories WIRING 3185 3186 SYSTEM ENVIZIO PRO II SHARP SHOOTER...

Page 70: ...68 Accessories WIRING 3187 3188 SYSTEM RAVEN 440 SHARP SHOOTER...

Page 74: ...72 Accessories 15 743 MANIFOLD VALVE DRAWING...

Page 76: ...74 Accessories 17 580 20 HEAVY BOOM...

Page 78: ...76 Accessories 17 580 20 BOOM DRAWING...

Page 80: ...78 Accessories 17 585 18 HEAVY BOOM...

Page 82: ...80 Accessories 17 585 18 HEAVY BOOM...

Page 86: ...84 Accessories 30 010 ELECTRIC HOSE REEL DRAWING...

Page 90: ...88 Accessories HOSE REEL MOUNT DRAWING...

Page 92: ...90 Accessories 30 004 FOAM MARKER DRAWING WIRING DRAWING...

Page 94: ...92 Accessories 30 004 FOAM MARKER DRAWING...

Page 96: ...94 Accessories FOAMER NOZZLE MOUNT HOSE GUARD MOUNT DRAWING...

Page 99: ...97 Accessories NOTES...

Page 102: ...100 Accessories 30 006 FRESH WATER TANK DRAWING...

Page 106: ...104 Accessories 15 620 CHEMICAL CLEAN LOAD PARTS DRAWING...