8

Introduction

PARTS MANUALS AVAILABLE ONLINE AT smithco.com

SETUP

The Spray Star 5200 arrives from

Smithco

setup and ready for service. Depending on freight conditions bat-

tery installed.

The spray system is normally shipped attached to the 5200 Prime Mover. If a spray system is to be fitted to a

Prime Mover by a dealer or factory, assemble and attach the components in accordance with the parts draw-

ings in the

Spray Star 5200 Parts/Service Manual.

1. Check the tire pressure. The front tires and rear tires are

30 psi (2.0 bar).

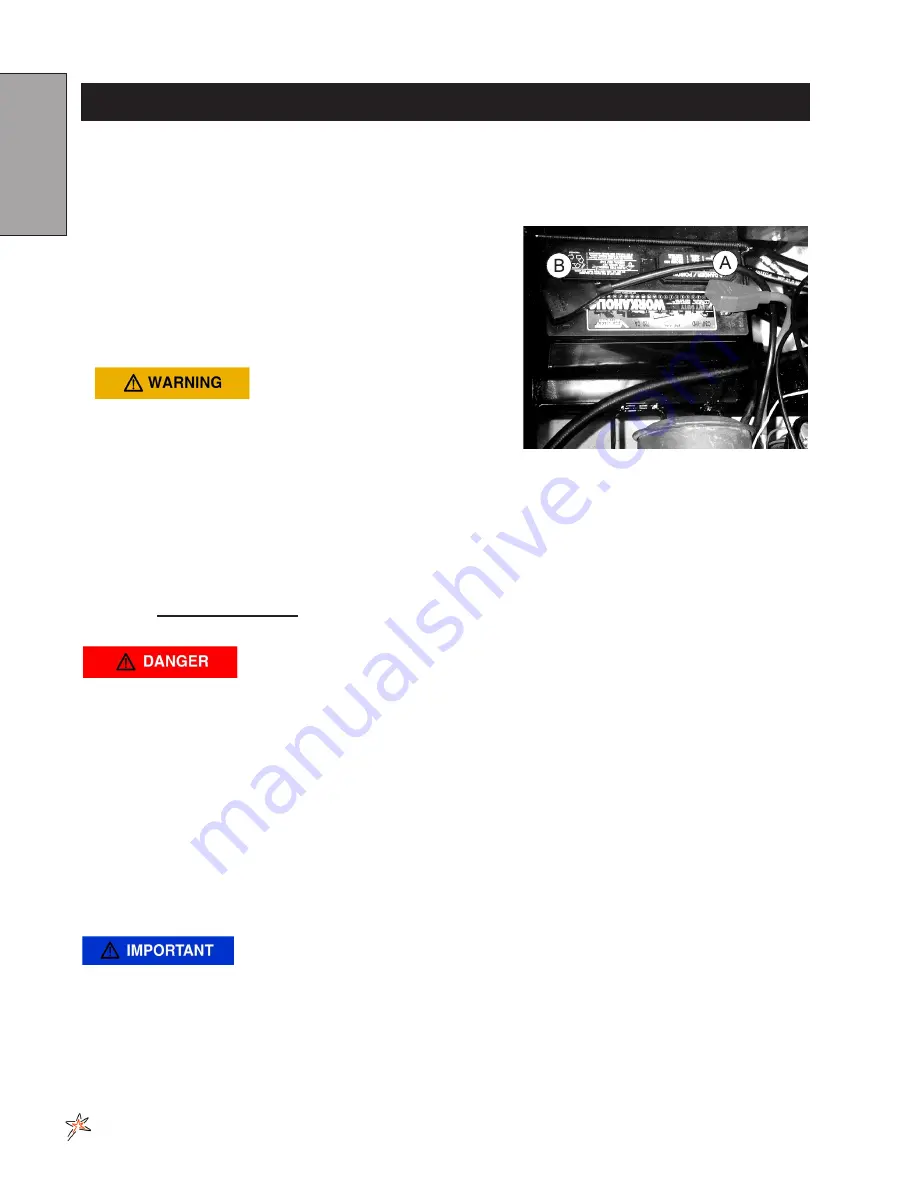

2. Battery is located under center console. Turn lock clock-

wiseadn raise console panel. This is a negative grounding

system.

Connecting battery cables to

the wrong post could result in

personal injury and/or damage to

the electrical system. Make sure

battery and cables do not inter-

fere or rub on any moving part.

Connect red positive (+) cable

(A) to battery first. When discon

-

necting remove black negative (-) cable (B) first.

3. Check hydraulic fluid level in tank located under the seat. Remove cap and add SAE 10W-40 API Ser

-

vice SJ or higher motor oil if necessary. Fluid level should be about 2-2

1

/

2

" (5-6.4 cm) from the top of the

tank when cold. DO NOT OVERFILL.

4. Fill fuel tank, located on right side, with Unleaded 87 Octane Gasoline Minimum. When filling the fuel

tank stop when the fuel reaches 1 inch (2.54cm) from the top. This space is necessary for fuel expan

-

sion.

DO NOT OVERFILL.

Fuel is flammable, caution must be used when storing or handling it. Do not

fill fuel tank while engine is running or an enclosed area, fumes are explosive

and dangerous to inhale. DO NOT SMOKE while filling the fuel tank. DO NOT

OVERFILL

5. Machine should be greased before starting, refer to

Spray Star 5200 Parts/Service Manual

for location.

6. Attach the Spray Boom and any other Optional Equipment to the Prime Mover, in accordance with

instructions in the

Spray Star 5200 Parts/Service Manual

. The nozzles must be the correct distance

above the turf as described in

Turf Spraying Guide

. The spray boom must operate properly and the

outer sections must break away safely if an object is struck by them, they must then return to normal

operation position.

7. Be sure to double check boom heights, nozzle spacing and displacement before spraying.

8. Machine is shipped with windshield washer fluid in to prevent freezing. Flush system completely with

clear water. Fill tank with water and re-tighten the four bolts used to hold the tank in place.

9. Read operating instructions before starting.

Never allow pump to run dry! The valve on the suction side of the pump (be-

tween the pump and tank) must be fully open whenever the pump is operated.