12

Introduction

SETUP

The Bunker Rakes arrive from

Smithco

Smithco

Smithco

Smithco

Smithco

with some assembly required before service.

1. Set park brake. Push the brake down past center and

the park brake is engaged.

2. Rear wheel mounting. Block front tire. Jack up rear of

machine being careful not to damage underside of

machine. Place wheel on hub lining up bolt holes. Use

the ten lug nuts provided. Then torque to 64 - 74 ft/lb

(87-100 Nm) using a cross pattern. Retorque after the

first 10 hours and every 200 hours thereafter. Lower

machine to ground and remove blocks and jack.

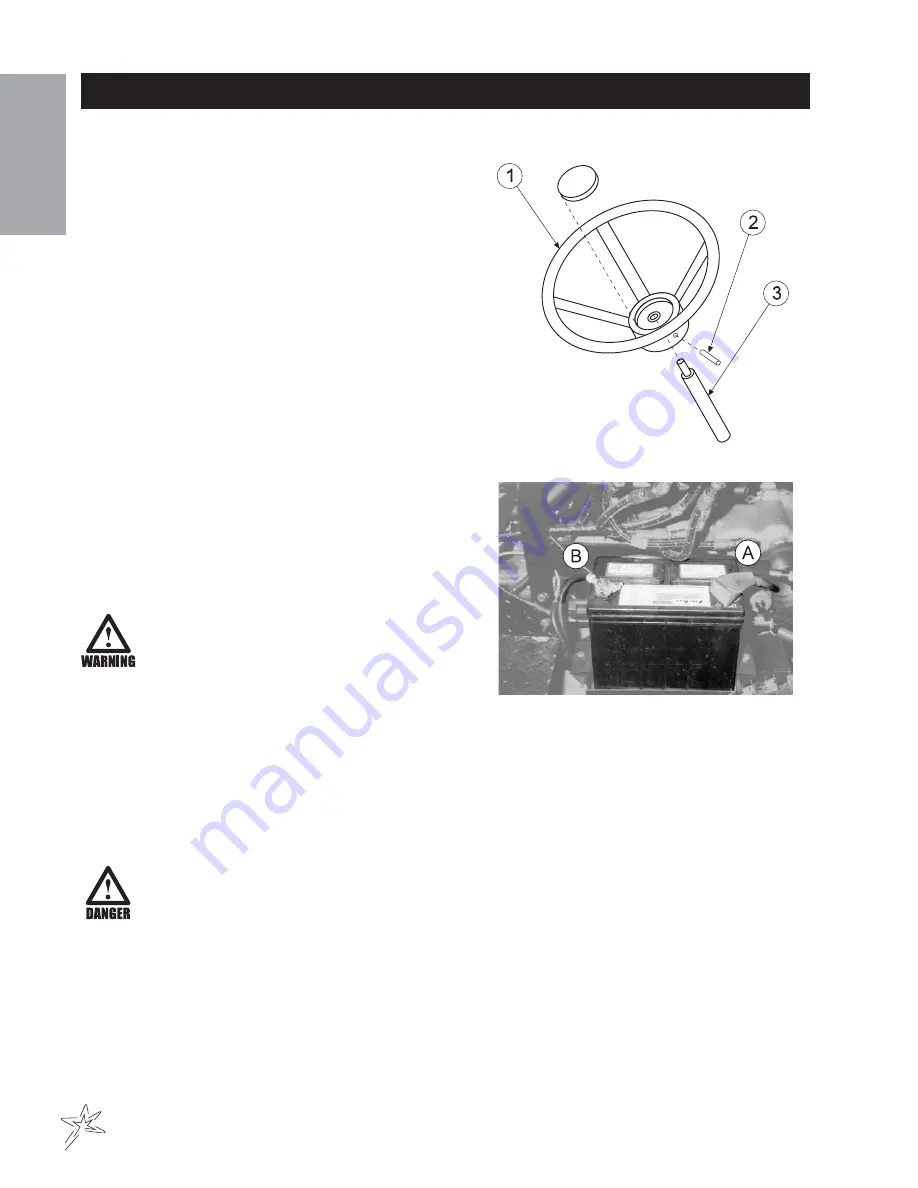

3. Install steering wheel (Ref 1) on machine. Put steer-

ing wheel onto shaft (Ref 3) Line up holes and insert

1

/

4

x 2" Roll Pin (Ref 2) into wheel shaft. Tighten set

screw.

4. Check the tire pressure. The tire pressure should be

5 psi (0.35 bar)

5. Battery not furnished. Install an automotive type 45 -

12 volt; 480 cold cranking amps (minimum) battery in

the battery box of the Super Rakes and Super Stars

This is a negative grounding system. Attach the

battery hold-downs. Then attach red positive (+) cable

(A) to positive terminal. Slide rubber boot over the

positive terminal to prevent shorts. Attach black

negative (-) cable (B) to the negative terminal.

Connecting battery cables to the wrong post

could result in personal injury and/or damage

to the electrical system. Make sure battery and

cables do not interfere or rub on any moving

part. Connect the red positive (+) cable (A) to

the battery first. When disconnecting remove

the black negative (-) cable (B) first.

6. Check engine oil and add as necessary. See engine manual for recommended motor oil. DO NOT

OVERFILL.

7. Fill Gas Tanks with Unleaded 87 Octane gasoline (minimum).

Fill Diesel Tanks with Diesel No. 2.

Gasoline is flammable. Caution must be used when storing or handling it. Do not fill fuel tank

while engine is operating or in an enclosed area. Fumes are explosive and dangerous to

inhale. DO NOT SMOKE while filling the fuel tank. DO NOT OVERFILL.

8. Check hydraulic oil level on the tank. The level should be

2 -2

1

/

2

"(5 - 6.35 cm) from top of tank. If level is

low, add SAE 10W-40 API Service SJ or higher motor oil.

9. Machine should be greased before starting.

10. Read operating instructions before starting machine.

Summary of Contents for SUPER RAKE 13-550-D

Page 15: ...13 Introduction NOTES...

Page 28: ......