Summary of Contents for TCV 5000

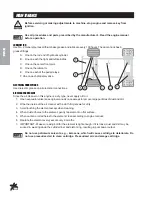

Page 13: ...11 Service NOTES...

Page 22: ...20 Diagrams BODY FRAMEDRAWING...

Page 24: ...22 Parts NOSE CONE DRAWING...

Page 26: ...24 Parts FRONTAXLEDRAWING...

Page 28: ...26 Parts OIL AND FUEL TANK DRAWING...

Page 30: ...28 Parts SEAT PANEL DRAWING...

Page 32: ...30 Parts ENGINE AND PUMPS DRAWING...

Page 34: ...32 Parts COOLER AND EXHAUST DRAWING...

Page 36: ...34 Parts 31 015 GONDOLA DUMP BOX DRAWING...

Page 38: ...36 Parts 31 028 CARGO TAILGATE BOX DRAWING...

Page 40: ...38 Parts 13 731 SINGLE BANK HYDRAULIC VALVE DRAWING...

Page 42: ...40 Parts 15 301 ORBITROL DRAWING...

Page 44: ...42 Parts 30 102 EATON PUMP DRAWING...

Page 46: ...44 Parts 30 102 EATON PUMP DRAWING...