www.smoothfitness.com

27

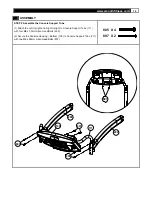

STABILIZER ADJUSTMENT

How to level the treadmill

:

An uneven floor or improper stabilizer level can cause the treadmill to wobble during use as well as

the incline adjustment to function incorrectly. Please follow the procedure described below to

make sure the treadmill stabilizer is adjusted correctly prior to use. You may need the assistance

of another person to perform this adjustment.

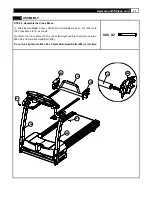

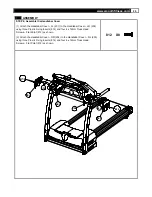

1. There are four stabilizers and two cushions

located on the underside of the treadmill as shown

in drawing

1

. These all need to sit firmly on the

floor to prevent the treadmill from wobbling during

use.

1.

Four stabilizers towards the rear and two cushions at

the front.

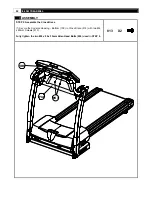

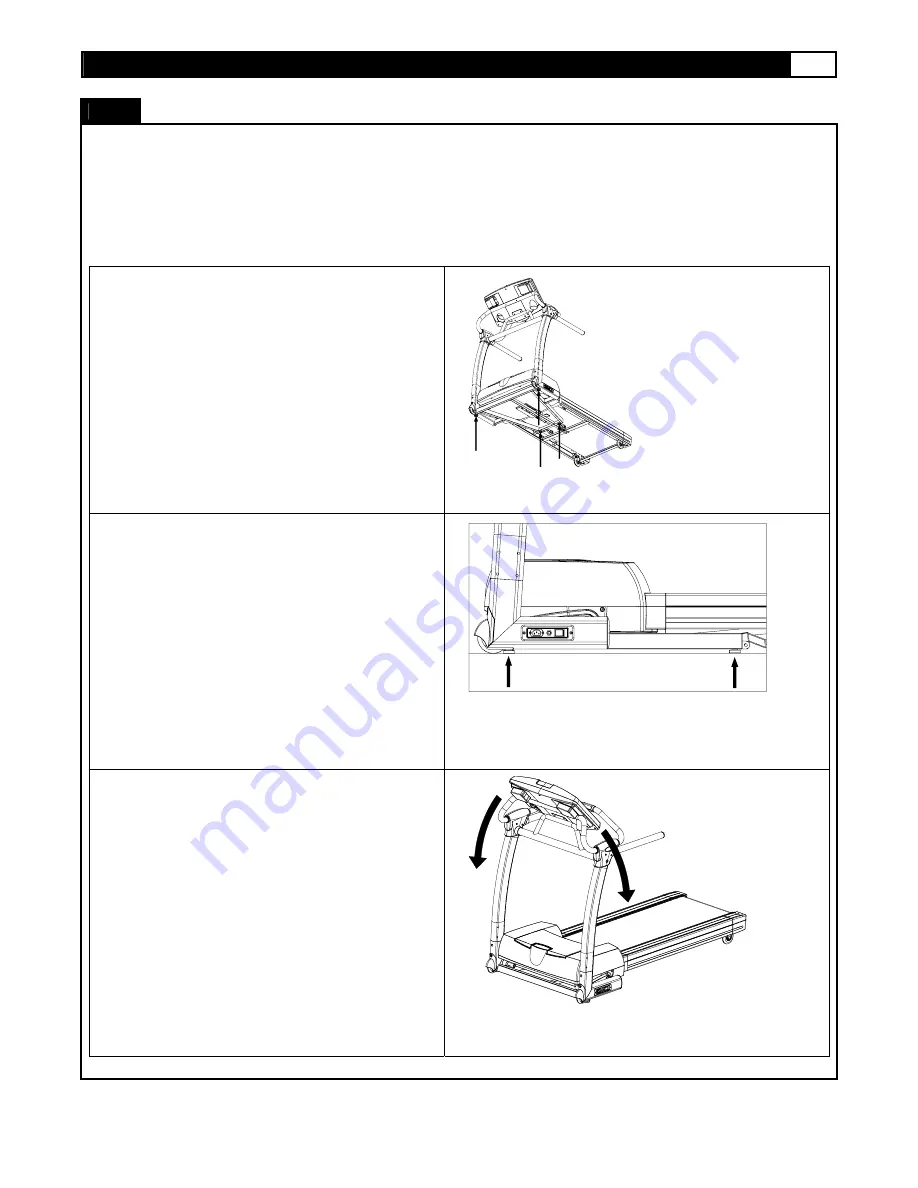

2. Inspect each side of the treadmill base frame.

The treadmill should sit on the floor with all four

stabilizers and both cushions resting firmly on the

floor as shown in drawing

2

. Shake the

handlebars back and forth to check if they are

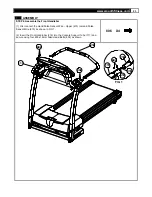

resting firmly on the floor. If they are not, tilt the

treadmill to one side to adjust the stabilizers as

shown in drawing

3

. Simply turn the stabilizers like

a screw to adjust their heights. Repeat this until

the treadmill sits firmly on the floor.

2.

Check position of stabilizers and cushions.

3.

Tilt treadmill to access stabilizers.