Summary of Contents for 9.45TV

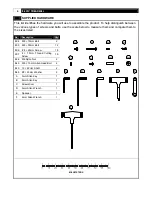

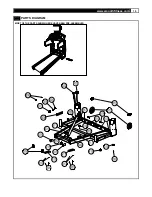

Page 12: ...12 9 45TV TREADMILL PARTS DIAGRAM MOST OF THE PARTS SHOWN HERE HAVE BEEN PRE ASSEMBLED ...

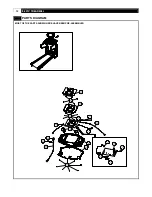

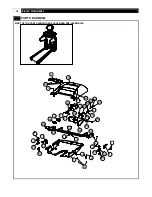

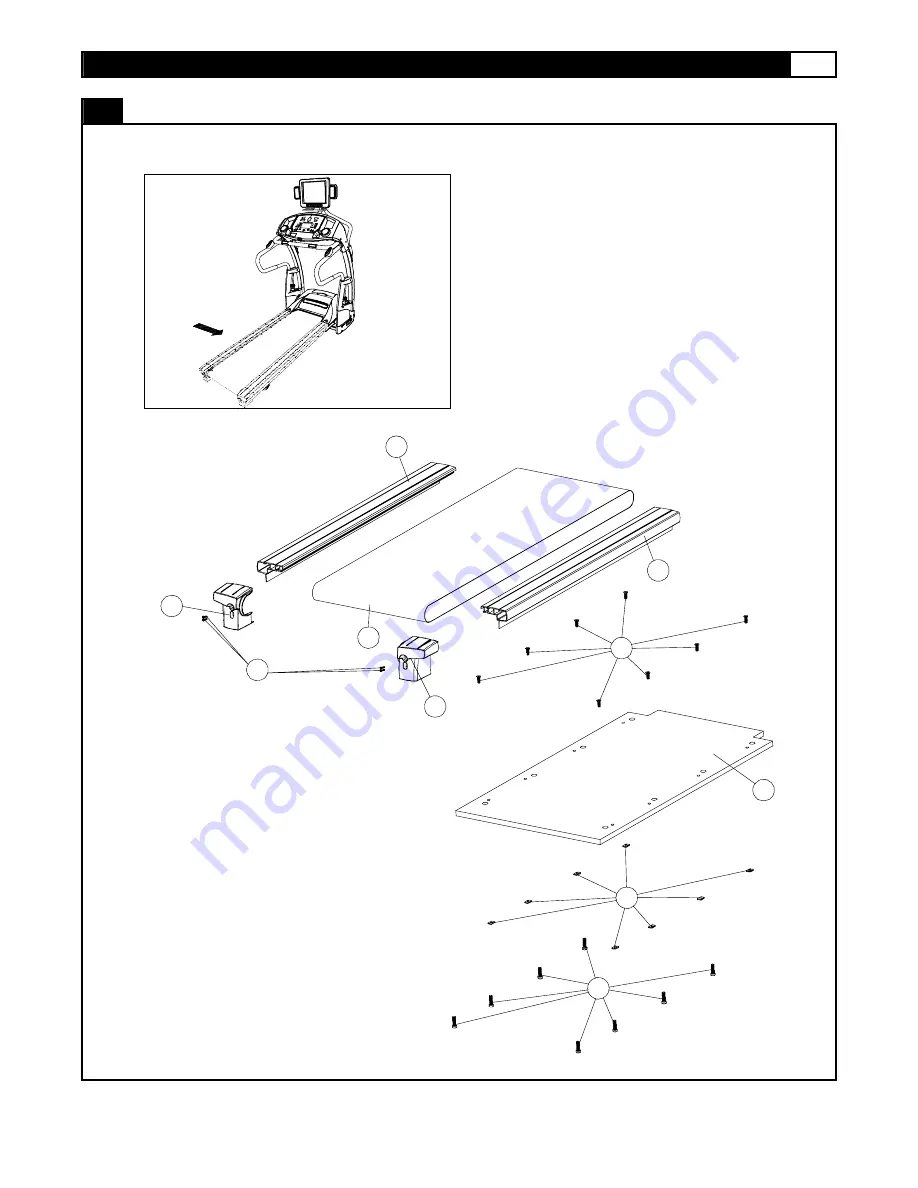

Page 13: ...www smoothfitness com 13 PARTS DIAGRAM MOST OF THE PARTS SHOWN HERE HAVE BEEN PRE ASSEMBLED ...

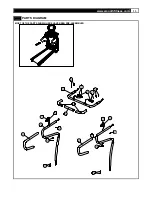

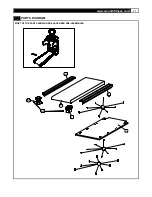

Page 15: ...www smoothfitness com 15 PARTS DIAGRAM MOST OF THE PARTS SHOWN HERE HAVE BEEN PRE ASSEMBLED ...