4

“

H

ARDWARE

I

DENTIFICATION

C

HART

”

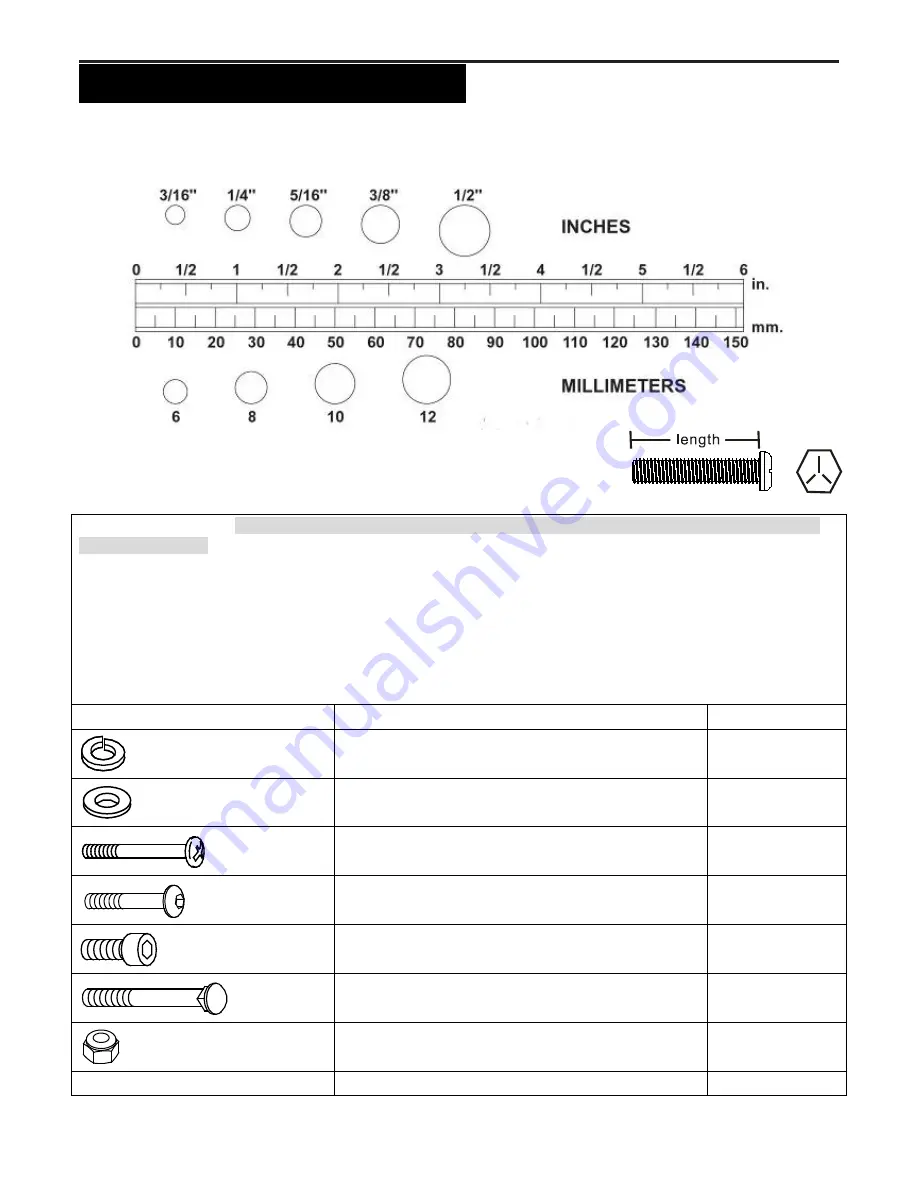

Unpack the box in a clear area. Follow the

List of Hardware Kit

below. This chart is provided to help identify the hardware

used in the assembly process. Place the washers, the end of bolts, or screws on the circles to check for the correct

diameter. Use the small scale to check the length of the bolts and screws. Do not dispose of the packing material.

NOTICE:

The length of all bolts and screws except those with flat heads is

Measured from below the head to the end of the bolt or screw. Flat head

bolts and screws are measured from the top of the head to the end of the

bolt or screw

After unpacking the unit,

please note that there are 3 hardware bags (HARDWARE KIT A, HARDWARE KIT B and

HARDWARE KIT C)

.

Assembly’s

Step 1 ~ 5

: Will use HARDWARE KIT

A

Assembly’s

Step 6 ~ 10

: Will use HARDWARE KIT

B

Assembly’s

Step 11 ~ 12

:

Will use HARDWARE KIT

C

Note:

Please review the list below to ensure that the contents are present (A, B and C)

Some small parts may have been pre-attached for shipping purposes. If a part is not present in the hardware bag, check to

see if it has been pre-assembled

HARDWARE KIT

A

Part No. and Description

Q’TY

121 Lock Washer (M8)

4 pcs

124 Washer (8x23x2.0t)

2 pcs

139 Screw, Round Head (M5xp0.8x40mm)

1 pcs

154 Bolt, Button Head (M8xp1.25x30mm)

2 pcs

162 Bolt, Socket Head (M8xp1.25x70mm)

2 pcs

164 Carriage Bolt (M8xp1.25x90mm)

2 pcs

171 Nylock Nut (M8xp1.25)

2 pcs

Summary of Contents for V2300

Page 24: ...24 PRODUCT PARTS DRAWING A ...

Page 25: ...25 PRODUCT PARTS DRAWING B ...