4.0 Manual Metal Arc Welding Process

(MMAW)

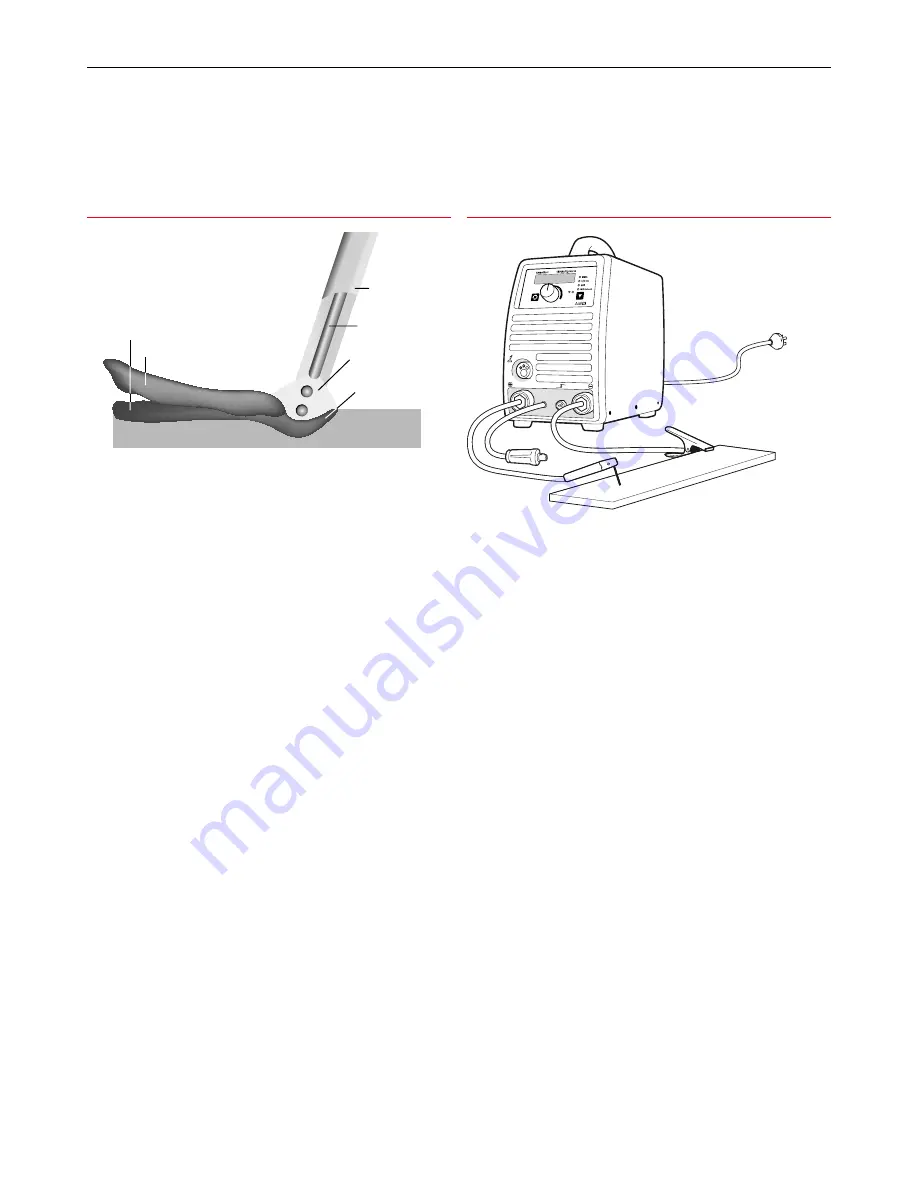

TIG Welding techniques

Weld Metal

Slag

Core Wire

Flux Covering

Arc

Weld Pool

Workpiece

4.1 Process

Manual Metal Arc welding is the process of joining metals where an

electric arc is struck between the metal to be welded (parent metal) and

a flux-coated filler wire (the electrode). The heat of the arc melts the

parent metal and the electrode which mix together to form, on cooling, a

continuous solid mass.

Before arc welding can be carried out, a suitable power source is

required. Two types of power sources may be used for arc welding, direct

current (DC) or alternating current (AC).

The essential difference between these two power sources is that, in the

case of DC, the current remains constant in magnitude and flows in the

same direction. Similarly, the voltage in the circuit remains constant in

magnitude and polarity (i.e. positive or negative).

In the case of AC however, the current flows first in one direction and

then the other. Similarly, the voltage in the circuit changes from positive

to negative with changes in direction of current flow. This complete

reversal is called a ‘half cycle’ and repeats as long as the current

flows. The rate of change of direction of current flow is known as the

‘frequency’ of the supply and is measured by the number of cycles

completed per second. The standard frequency of the AC supply in

Australia is 50 Hz (Hertz).

4.2 Welding Machine

The most important consideration when contemplating the use of arc

welding for the first time is the purchase of a suitable welding machine.

BOC supplies a popular range of arc welding machines. Machines

range from small portable welders that operate from standard 240

Volt household power to heavy-duty welders used by the largest steel

fabricators.

Basic Welding Machine and Cables

The choice of welding machine is based mostly on the following factors:

• primary voltage, e.g. 240 Volt or 380 Volt

• output amperage required, e.g. 140 amps

• output required, e.g. AC or DC +/-

• duty cycle required, e.g. 35% @ 140 amps

• method of cooling, e.g. air-cooled or oil-cooled method of output

amperage control, e.g. tapped secondary lugs

• or infinitely variable control.

For example, the Smootharc 175 Multiprocess connects to 240 Volt

supply (15 amps Input), has an output of 175 amps DC @ 35% duty

cycle.

Having decided on a welding machine, appropriate accessories are

required. These are items such as welding cables, clamps, electrode

holder, chipping hammer, helmet, shaded and clear lenses, scull cap,

gloves and other personal protective equipment.

BOC stocks a huge range of personal protective equipment. This

combined with BOC’s extensive network ensures fast reliable service

throughout the South Pacific.

25

BOC Smootharc 180 Multiprocess operating manual

Installation for MMA process

Summary of Contents for 180 Multiprocess

Page 1: ...180 Multiprocess Operating manual 6PRRWKDUF GYDQF GYDQF ...

Page 45: ...45 BOC Smootharc 180 Multiprocess operating manual ...

Page 53: ......

Page 54: ......

Page 55: ......