© SMP (PLAYGROUNDS) LTD, TEN ACRE LANE, THORPE, EGHAM, SURREY, TW20 8RJ

POLYNESIA SPRINGERS

Section 1 Page 3

3

INSTALLATION & ASSY PROCEDURES

PRE-INSTALLATION INSPECTION :

Inspect all parts for damage (that may have occurred during transportation &

storage). Finish Coatings, if found to be damaged these should be made good

before erection. Any damaged or missing parts must be replaced.

i)

Warn the public of the risk of injury, by placing signs and fencing the

surrounding area, before commencing installation.

ii)

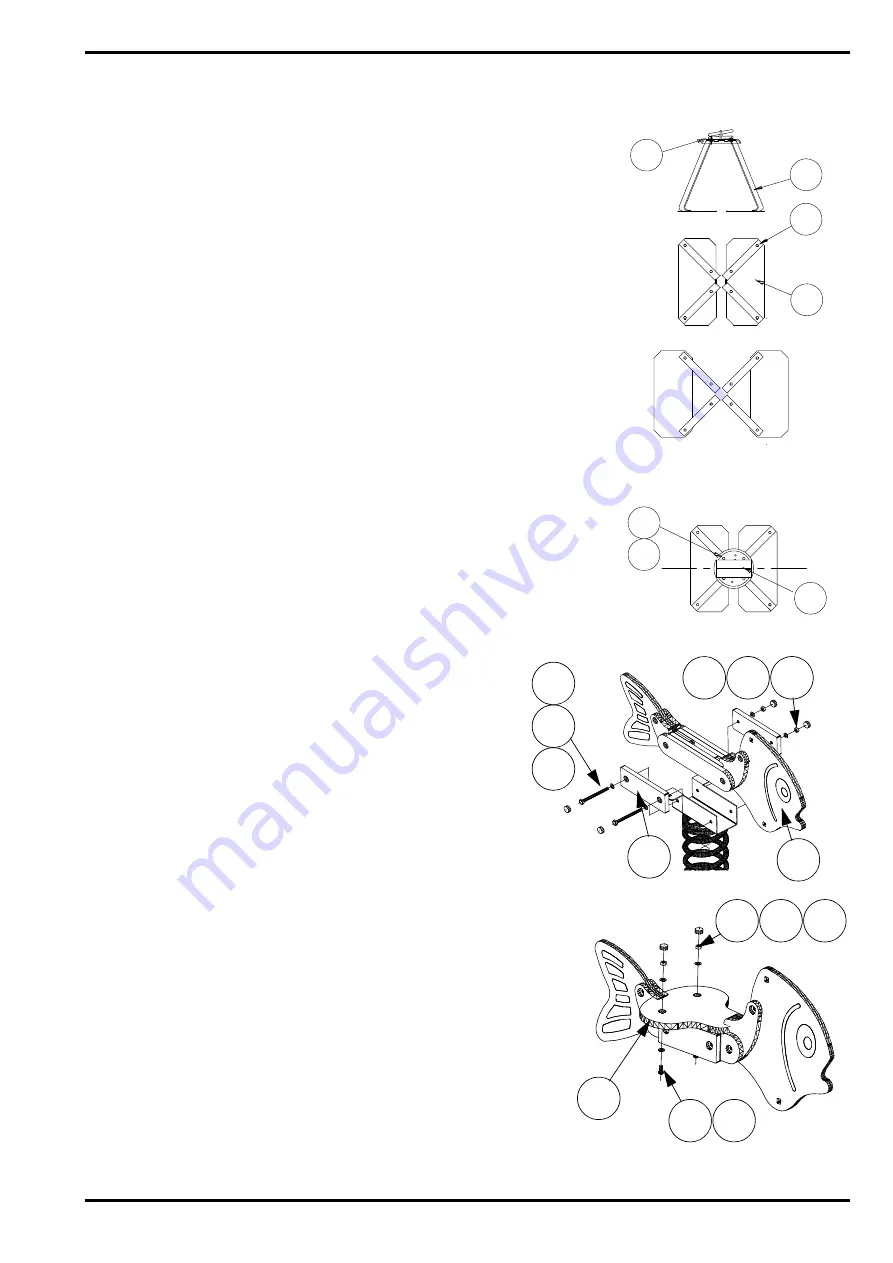

Note if the installation is 'standard' or 'loose fill',then assemble the base

supports (1.3) to the base plates (1.4) the appropriate way round using 4-

off Torx bolts (1.9) and fully secure.(Fig 3).

iii)

Align the base sub-assy onto the spring sub-assy (1.2) in the angular

position shown in Fig 4.

iv)

Assemble the spring sub-assy onto the base sub-assy using 4-off Torx

bolts (1.9) and washers (1.6).Tighten Torx bolts to a torque setting

between 40-43 Nm (30-32 lbf ft). (Fig 4).

v)

Position the unit, mark out the foundation holes (Figs 1 & 2). Place the

unit to one side and excavate the holes. If applicable refer to the site

plan for unit location.

vi)

Place the unit into the hole, then level and square the unit. Pour

concrete into the hole to a minimum thickness of 100mm (Figs 1 & 2).

Allow to cure before continuing (Recommended initial curing time is 48

hours minimum).

vii) Backfill the hole with earth to the required level, taking into

account any 'impact absorbing surfacing requirements'

(Figs 1 & 2). Refer to separate instructions if applicable.

viii) Place body sub-assy (1.1) onto spring & base sub-assy.

Align holes. Place bolt (1.5) thro' plain washer (1.6) and

outer poly cover with c'bore facing outermost (1.11) & feed

thro' spring sub assy & body sub assy. Fit washer (1.6) &

nut (1.7).Tighten bolts to a torque setting between 24-27

Nm (18-20 lbf ft).(Fig 5).

ix)

Place the seat (1.12) into position, tucking front of seat into

slot on profile. From underside, place bolt (1.10) thro' plain

washer (1.6) & feed thro' holes in spring sub-assy & seat holes.

Fit washer (1.6) and nut (1.7).Tighten bolts to a torque setting

between 24-27 Nm (18-20 lbf ft).(Fig 6).

x)

Tap plastic cap (1.8) into recess on both sides of body & seat top

face, ensuring they finish flush with the surrounding plastic

surface with no sharp edges.

1.2

1.3

1.9

1.4

STANDARD INSTALLATION

LOOSE FILL INSTALLATION

Fig 3

¤

¤

1.6

1.9

Fig 4

PROFILE

1.2

FIG.5

1.6 1.7 1.8

1.1

1.8

1.6

1.11

1.5

1.6

1.8

1.7

1.6

1.10

1.12

ISSUE N

FIG.6

Summary of Contents for SPBIK

Page 2: ...INTENTIONALLY LEFT BLANK...