© SMP (PLAYGROUNDS) LTD, TEN ACRE LANE, THORPE, EGHAM, SURREY, TW20 8RJ

POLYNESIA SPRINGERS

Appendix A Page 1

Appendix A: SUB-ASSEMBLIES

The assemblies described below are for the spring and profile sub-assemblies. These will be supplied complete by

SMP. Instructions are included should the units need to be dis-assembled.

1

SPRING SUB-ASSEMBLY (CODE 86559999)

PARTS LIST

i)

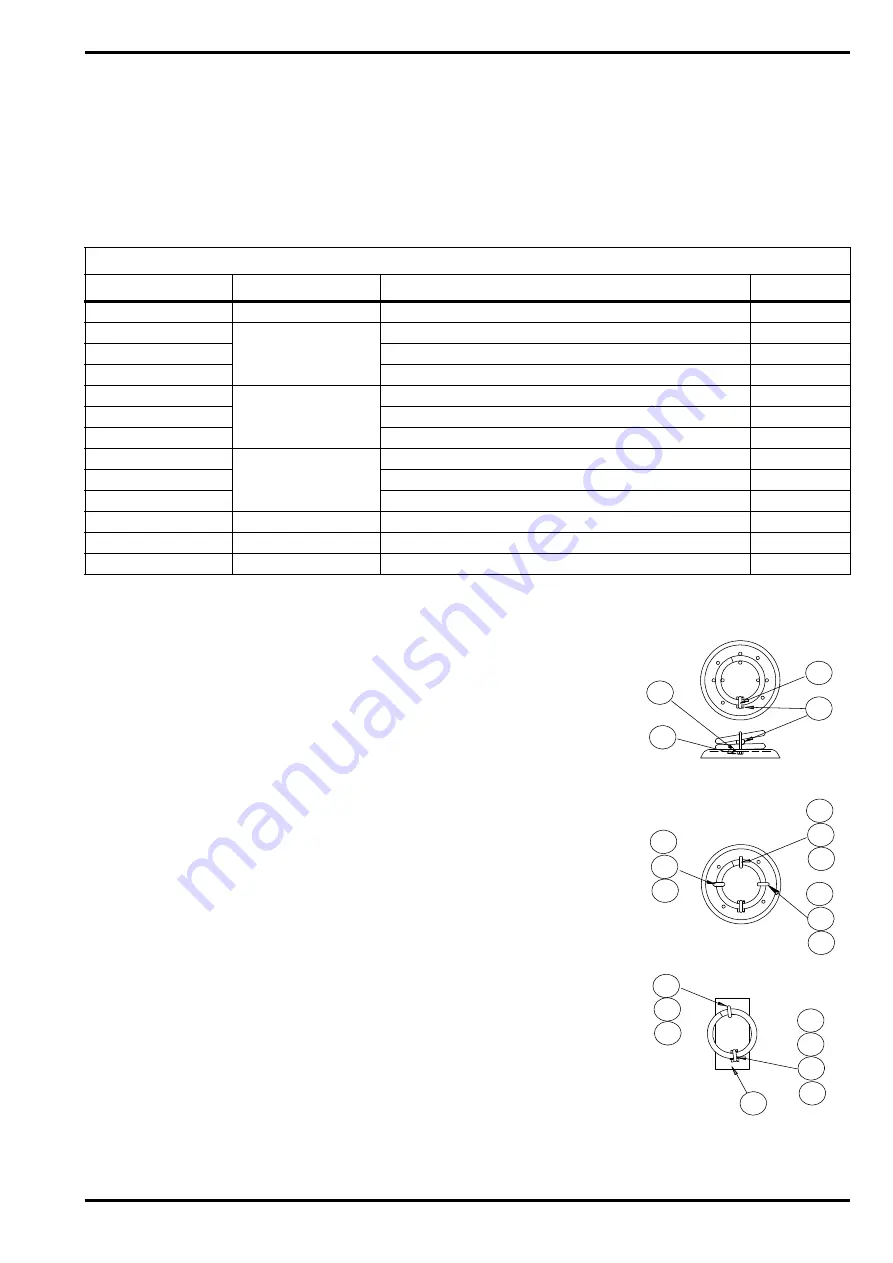

Place U-bolt (2.8) over the spring approximately one coil up from the base.

Locate the clamping block (2.11) over the threaded ends of the U-bolt,

ensuring that the taper and the curved face of the block are the correct way

round. "Wind" the bolt and clamping block down the spring until it is pinched

between the spring coils and over the holes in the base mounting. Place the

threads in the holes and secure in position with M12 nuts (2.9) and washers

(2.10). Do not tighten (Fig 7).

ii)

Place U-bolt (2.5) over the first two coils and through the base mounting.

Place the remaining two U-bolts (2.2) over the first coil and through the

base mounting. Secure in position with M12 nuts (2.3) and washers (2.4).

(Fig 8).

iii)

Place the top mounting bracket (2.13) onto the spring assy in the position

shown so that it is in line with the four fixing holes of the base plate (Figs 8

& 9).

iv)

Place U-bolt (2.8) over the first two coils. Locate the clamping block (2.11)

over the threaded ends of the U-bolt, ensuring that the taper and the curved

face of the block are the correct way round, and through the top mounting

bracket (2.13). Place the remaining U-bolt (2.2) over the first coil and

through the top mounting bracket. Secure in position with M12 nuts (2.3)

and washers (2.4). Tighten the nuts evenly until the spring is fully secured

and in alignment with the base plate to a final torque setting between 34-38

Nm (25-27 lbf ft) (Fig 9).

SPRING SUB-ASSY

ITEM

CODE

DESCRIPTION

QTY.

2.1

86009003

BASE PLATE

1

2.2

86009006A

U-BOLT 43mm LONG

3

2.3

NYLOC NUT-M12

6

2.4

WASHER-PLAIN M12

6

2.5

86009006B

U-BOLT 55mm LONG

1

2.6

NYLOC NUT-M12

2

2.7

WASHER-PLAIN M12

2

2.8

86009006C

U-BOLT 69mm LONG

2

2.9

NYLOC NUT-M12

4

2.10

WASHER-PLAIN M12

4

2.11

86009007

CLAMPING BLOCK

2

2.12

86009005

SPRING

1

2.13

86559004

TOP MOUNTING

1

¤

Fig 7

2.8

2.9

2.10

2.11

¤

Fig 8

2.2

2.3

2.4

2.2

2.3

2.4

2.5

2.6

2.7

¤

Fig 9

2.2

2.3

2.4

2.8

2.9

2.10

2.11

2.13

ISSUE N

Summary of Contents for SPBIK

Page 2: ...INTENTIONALLY LEFT BLANK...