13

of

84

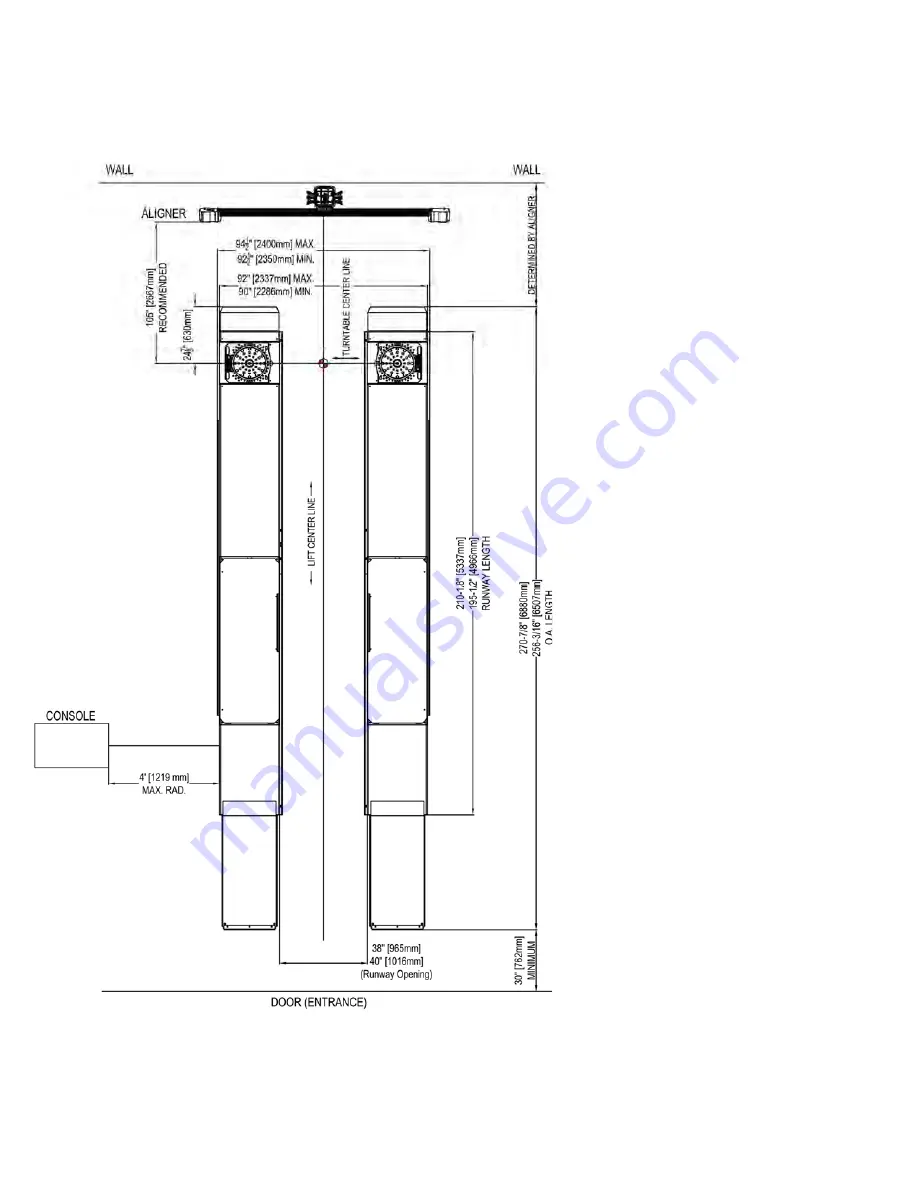

8.2 Surfacemount Bay Layout

NOTE:

Leave any additional room

for any desired aisle or work area.

Recommended clearance around

the equipment is a minimum of

three (3) feet. Ensure clearance

conforms to local building and fire

codes.

Recommended overhead clearance

is a minimum of twelve (12) foot

ceiling providing 6 feet for the

maximum lift height and 6 feet for

the supported vehicle. For vehicles

taller than 6 feet it is recommended

that the user provides additional

overhead clearance or a shut off

mechanism to stop the lift from

raising the vehicle too high.

Please contact customer service

for latest installation diagram as

it may change without notice.

Figure 3 - Typical Bay Layout

(Surface Mount)

Summary of Contents for EELR587A

Page 7: ...7 of 84 3 0 SAFETY WARNING DECALS...

Page 18: ...18 of 84 Figure 8 Hydraulic Connections...

Page 22: ...22 of 84 TO LEFT DECK ASSEMBLY Figure 11 Air Safety Auxiliary Air Connections...

Page 26: ...26 of 84 Figure 15b Optional LED Driver Box Circuit Connections...

Page 35: ...35 of 84 Figure 28 Filler Angle Installation...

Page 64: ...64 of 84 20 0 ACCESSORY ASSEMBLY 20 1 Front Turnplate...

Page 67: ...67 of 84 20 3 Airline Routing for Locking Turnplates and Rear Slip Plates...

Page 79: ...79 of 84 22 0 POWERPACK ASSEMBLY 22 1 Powerpack Assembly EAA0441V72A...