14

of

84

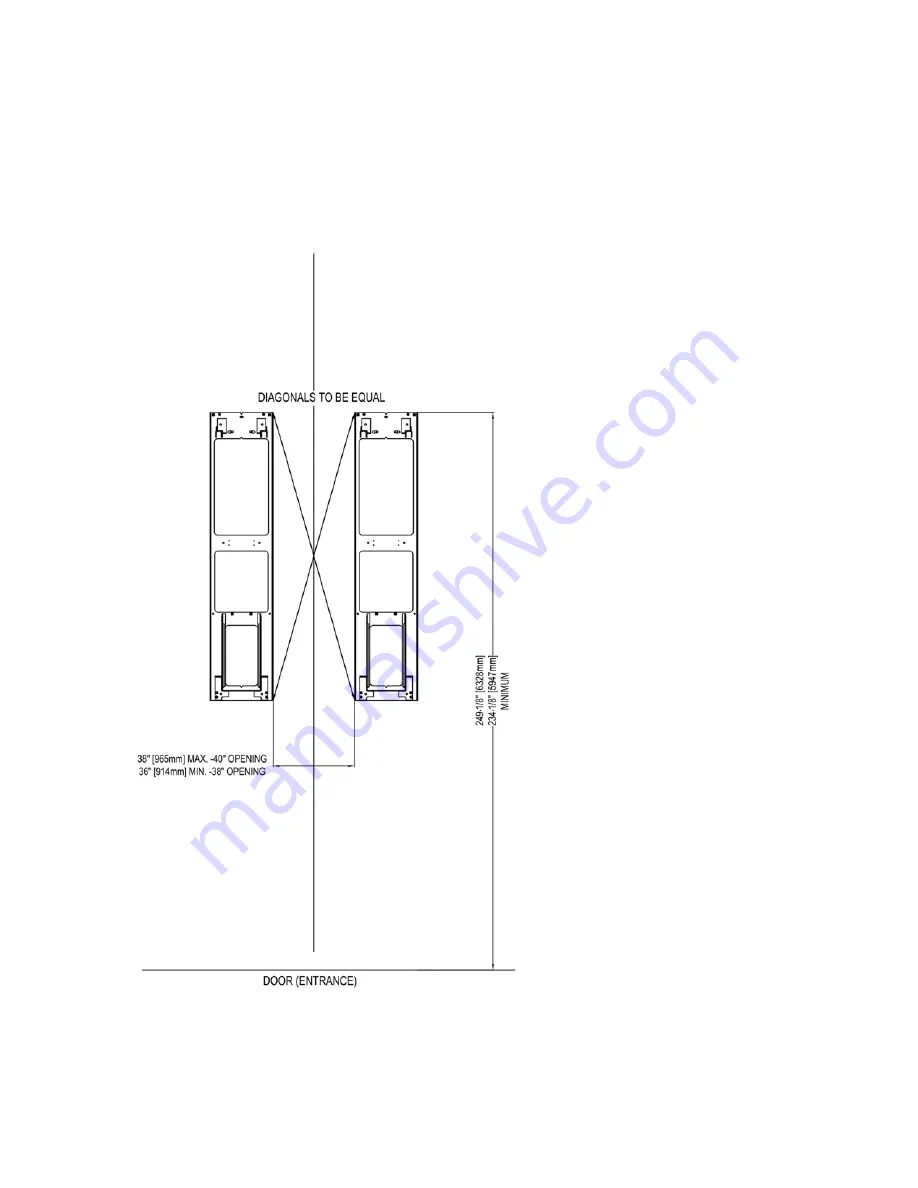

8.3 Baseframe Location

IMPORTANT: DO NOT CUT THE

SHIPPING STRAPS HOLDING

EACH SCISSOR ASSEMBLY

TOGETHER UNTIL

INSTRUCTED TO DO SO.

1. With reference to

Figure 3

,

the installer should locate the

most suitable location in the

shop for the lift.

2. Snap a chalk line for the

centerline of the lift ensuring

that it matches the centerline of

the bay door.

3. Measure and snap two (2)

parallel chalk lines on either

side the centerline for the

inside edges of the

baseframes. Refer to

Figure

4

for the dimensions

necessary to provide the

desired width between the

two runways. A distance of

36" (914mm) between the

baseframes will provide the

standard width of 38”

(965mm) between the inside

of the runways.

4. Measure and snap a chalk

line parallel to the shop door

for the front of the

baseframes, a minimum

distance of 249 1/8”

(6328mm) for the standard

length lift is recommended.

For short length lifts, use a

minimum of 234-1/8"

(5947mm).

5. Before proceeding, ensure

that once the runways are

installed adequate workspace

will remain in front of the lift. Refer to the minimum requirements listed in the installation and

operation manual of any alignment equipment as needed.

Figure 4 - Baseframe Locations

Summary of Contents for EELR587A

Page 7: ...7 of 84 3 0 SAFETY WARNING DECALS...

Page 18: ...18 of 84 Figure 8 Hydraulic Connections...

Page 22: ...22 of 84 TO LEFT DECK ASSEMBLY Figure 11 Air Safety Auxiliary Air Connections...

Page 26: ...26 of 84 Figure 15b Optional LED Driver Box Circuit Connections...

Page 35: ...35 of 84 Figure 28 Filler Angle Installation...

Page 64: ...64 of 84 20 0 ACCESSORY ASSEMBLY 20 1 Front Turnplate...

Page 67: ...67 of 84 20 3 Airline Routing for Locking Turnplates and Rear Slip Plates...

Page 79: ...79 of 84 22 0 POWERPACK ASSEMBLY 22 1 Powerpack Assembly EAA0441V72A...